Down-flow catalytic cracking/ cracking reactor for processing heavy raw oil

A cracking reactor and catalytic cracking technology, which is applied in the field of downward catalytic cracking/cracking reactors, can solve problems such as gas-solid back-mixing, downward sliding, axial and radial particle density, and uneven velocity distribution, so as to improve carbon burning Effects of conversion rate, reduction of secondary reactions, and control of contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

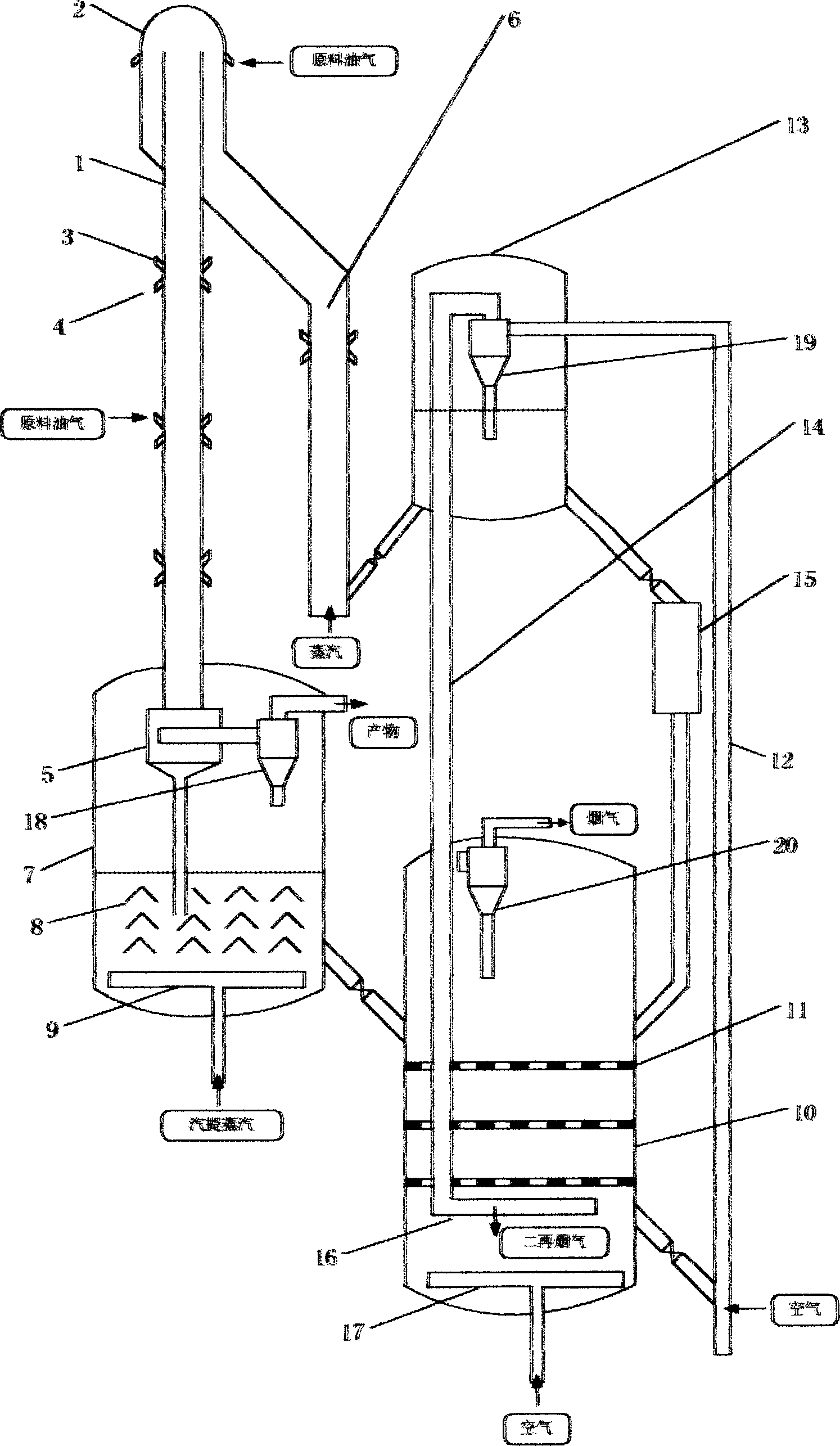

[0014] figure 1Shown is a down-flow FCC / cracking reactor processing a heavy feedstock. The downstream catalytic cracking / cracking reactor consists of a pre-riser connecting the gas-solid co-current downstream ultra-short contact catalytic reactor, a stripper and a two-stage regenerator. On the top of the down-flow catalytic cracking reactor 1, there is a dense-phase turbulent inlet 2 for the catalyst and raw oil gas; the down-bed reactor 1 and the pre-riser 6 are provided with secondary oil injectors 3 and 4; the down-bed reactor 1 The end of the main body is provided with a gas-solid rapid separation device 5, and the rear 5 of the separation device is provided with a stripper 7, and a ridge-shaped member 8 and a gas distributor 9 are provided in the stripper 7; The form enters the dense-phase turbulent inlet 2; the raw oil gas and atomized steam are sprayed through the multiple nozzles on the dense-phase turbulent inlet 2; the catalyst particles and atomized oil and gas are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com