Hydrogen production device and system for fuel cell with controllable hydrogen production rate

A technology for fuel cells and hydrogen production devices, which is applied in the fields of fuel cells, hydrogen production, hydrogen, etc., can solve the problems of difficult to accurately control the reaction rate, reduced system reliability and stability, and complicated processes, and achieves portability and application. Flexible, compact, system-flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

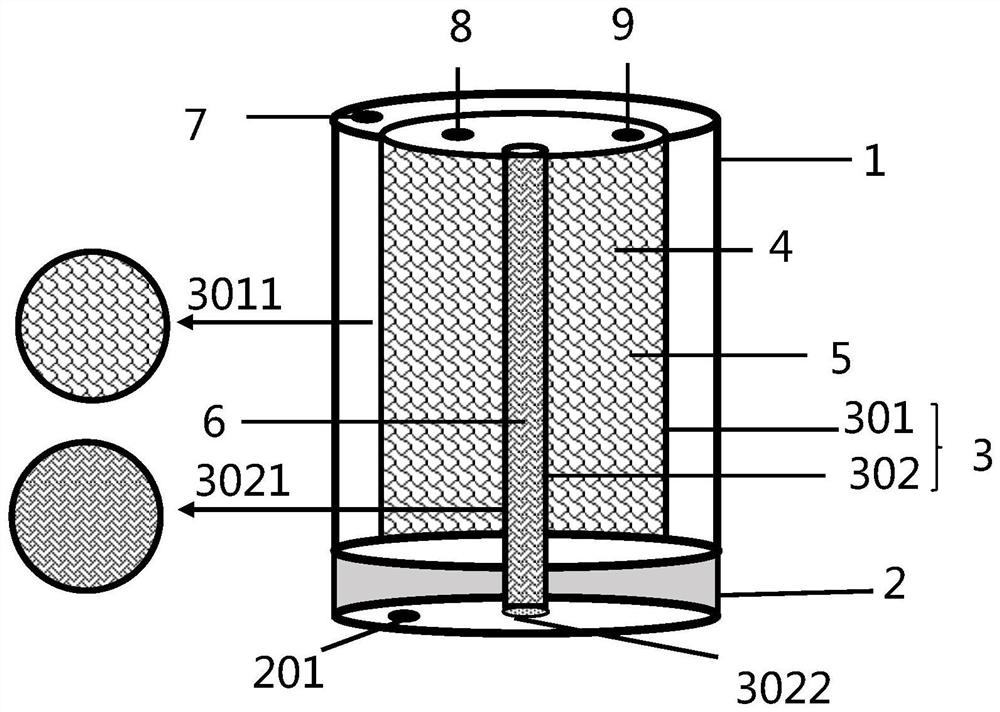

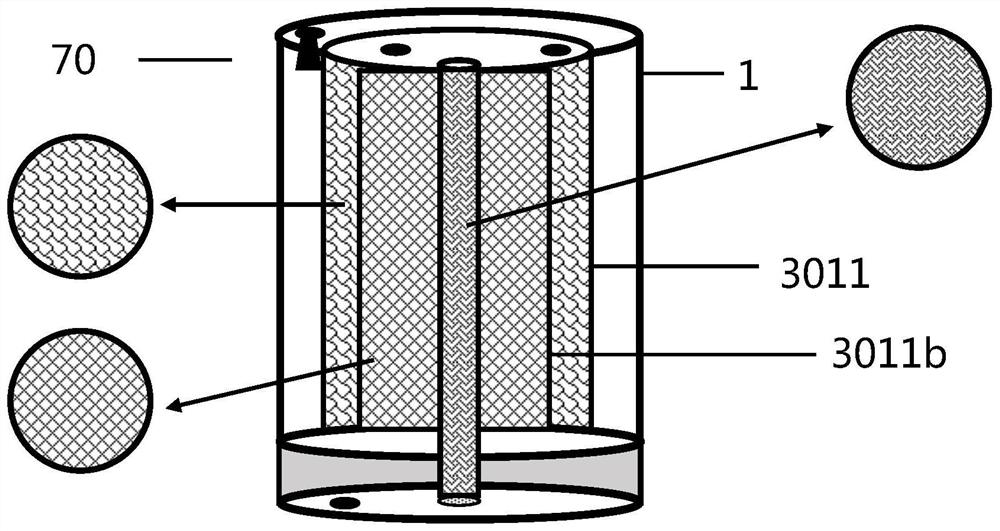

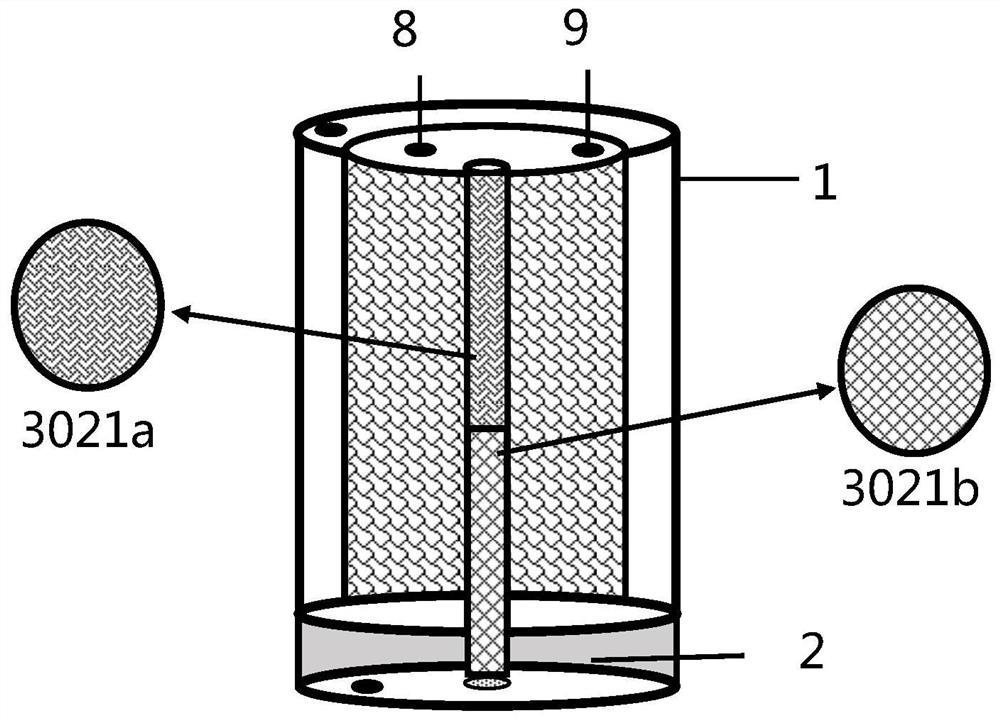

[0036] like Figure 1-Figure 4 As shown, the present embodiment provides a hydrogen production device with a controllable hydrogen production rate for a fuel cell, the device includes two overlapping tanks, the upper part is a hydrogen production tank 1, and the lower part is a waste water tank 2;

[0037] A sleeve assembly 3 is arranged in the hydrogen production tank 1, and a first hollow cavity 4 is formed between the outer wall of the sleeve assembly 3 and the inner wall of the hydrogen production tank 1. The sleeve assembly 3 includes an active substance filling tank 301 and a A water recovery tank 302, the water recovery tank 302 is located inside the active material filling tank 301, a second hollow cavity 5 is formed between the inner wall of the active material filling tank 301 and the outer wall of the water recovery tank 302, and the water recovery tank 302 runs through Hydrogen production tank 1 and waste water tank 2, a third hollow cavity 6 is formed between the ...

Embodiment 2

[0074] like Figure 7 As shown, this embodiment provides a hydrogen production system with a controllable hydrogen production rate for a fuel cell, including: a water storage tank, a hydrogen production device, a fuel cell stack, a water supply system, a water circulation system, and a hydrogen supply system, One end of the water supply system is connected to the water storage tank, and the other end is connected to the first feed port of the hydrogen production device. The fuel cell stack includes a hydrogen inlet and a hydrogen outlet, and the hydrogen inlet is connected to the gas outlet of the hydrogen production device. One end of the water circulation system is connected with the waste water outlet, and the other end is connected with the first feed port for recycling part of the water.

[0075] The water storage tank and the hydrogen production tank are connected by a pump or filled with a liquid absorbent core, and the liquid absorbent core material includes but is not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com