Formaldehyde fumigation and disinfection method and disinfection device thereof

A technology of fumigation, disinfection and sterilization device, applied in the direction of chemistry, gasification substances, etc., can solve the problems of complicated operation, fire hazard, formaldehyde poisoning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

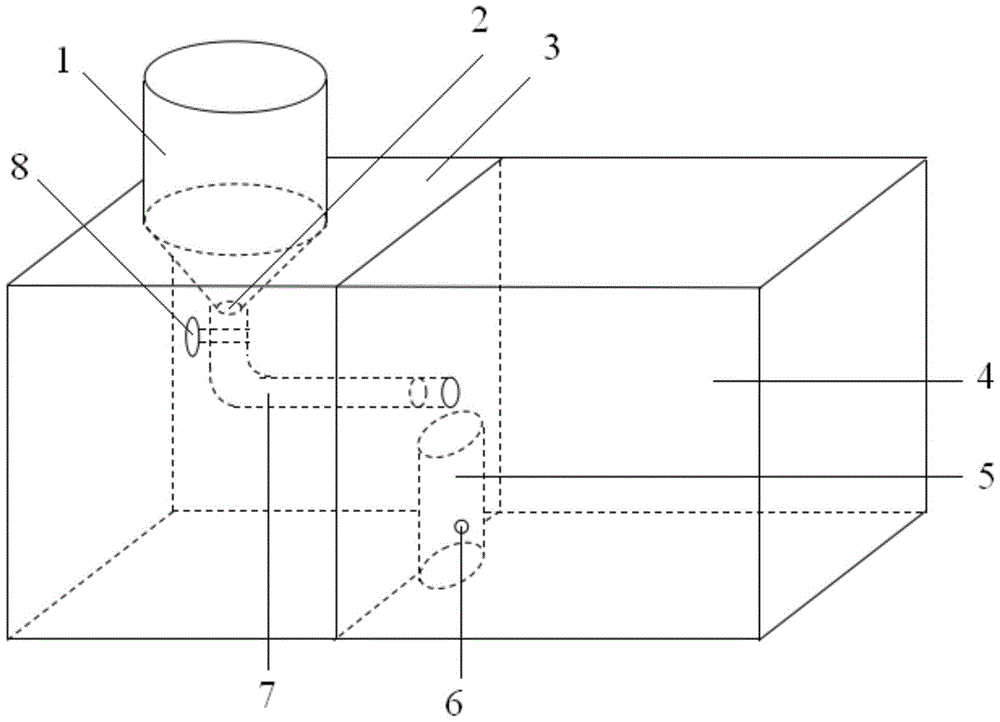

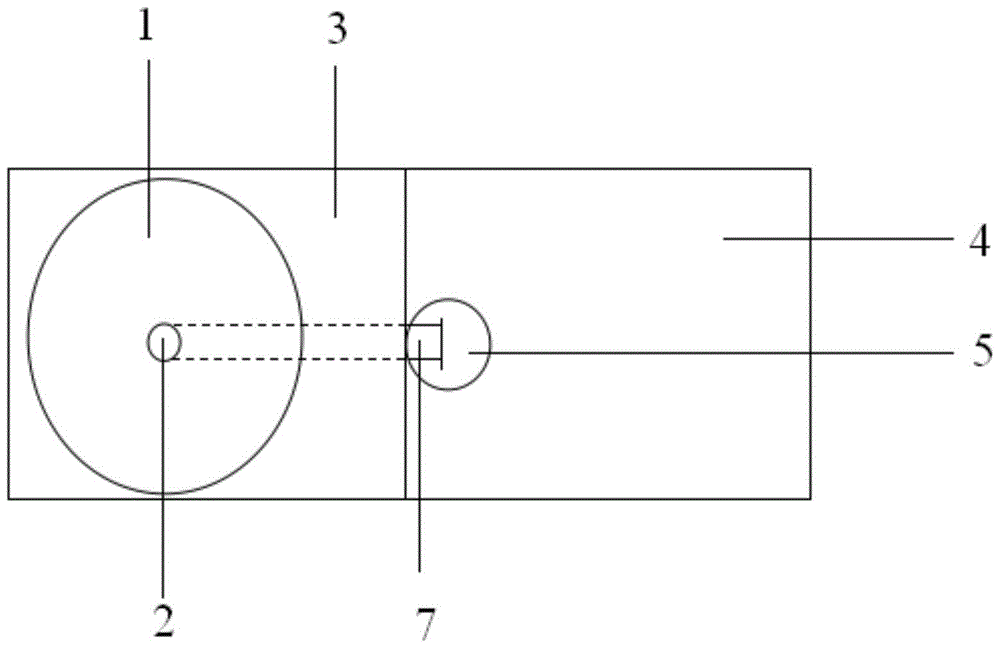

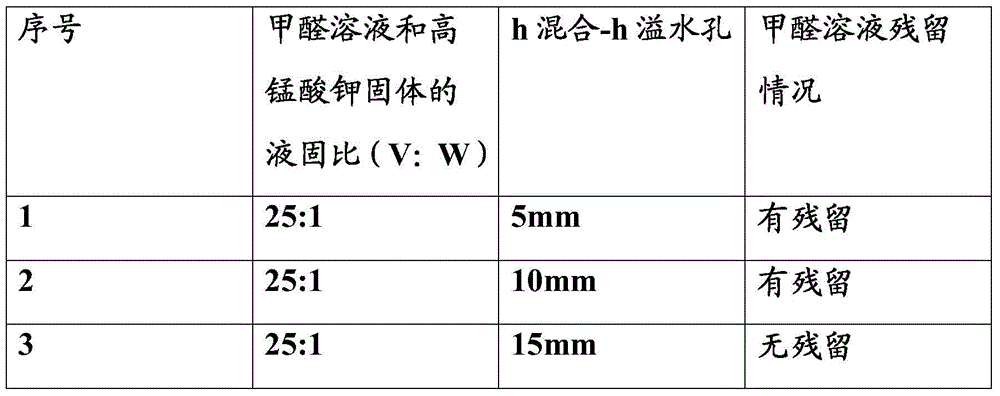

[0034] The height of the formaldehyde tank (1) from the ground is 38cm, the diameter of the small hole (2) in the bottom depression is 1mm, the bottom of the formaldehyde tank (1) is fixed on the support (3), the support (3) is a cube, at least one The side can be disassembled, the bracket (3) and the potassium permanganate tank (4) are combined to form a cuboid, the inner diameter of the formaldehyde delivery pipeline (7) is 1cm, and one end of the formaldehyde delivery pipeline (7) is welded to the formaldehyde tank (1) The bottom is communicated with the small hole (2), and the other end of the formaldehyde delivery pipeline (7) extends into the side wall of the potassium permanganate tank (4), and there is a time delay fixed at the bottom of the potassium permanganate tank below. Groove (5), formaldehyde conveying pipeline (7) stretches into the groove body that length does not exceed time-delay groove (5) at potassium permanganate tank (4) side wall, and formaldehyde conve...

Embodiment 2

[0039] The height of the formaldehyde tank (1) from the ground is 45cm, the diameter of the small hole (2) in the bottom recessed area is 1mm, the bottom of the formaldehyde tank (1) is fixed on the support (3), the support (3) is a cuboid, at least one The side can be disassembled, the bracket (3) and the potassium permanganate tank (4) are combined to form a cuboid, the inner diameter of the formaldehyde delivery pipeline (7) is 1cm, and one end of the formaldehyde delivery pipeline (7) is welded to the formaldehyde tank (1) The bottom is communicated with the small hole (2), and the other end of the formaldehyde delivery pipeline (7) extends into the side wall of the potassium permanganate tank (4), and there is a time delay fixed at the bottom of the potassium permanganate tank below. Groove (5), formaldehyde conveying pipeline (7) stretches into the groove body that length does not exceed time-delay groove (5) at potassium permanganate tank (4) side wall, and formaldehyde ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com