A system and process for producing olefins from organic oxygen-containing compounds with reduced catalyst coking

A compound and catalyst technology, applied in the field of organic oxygen-containing compounds, can solve the problem of rapid coking on the catalyst surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

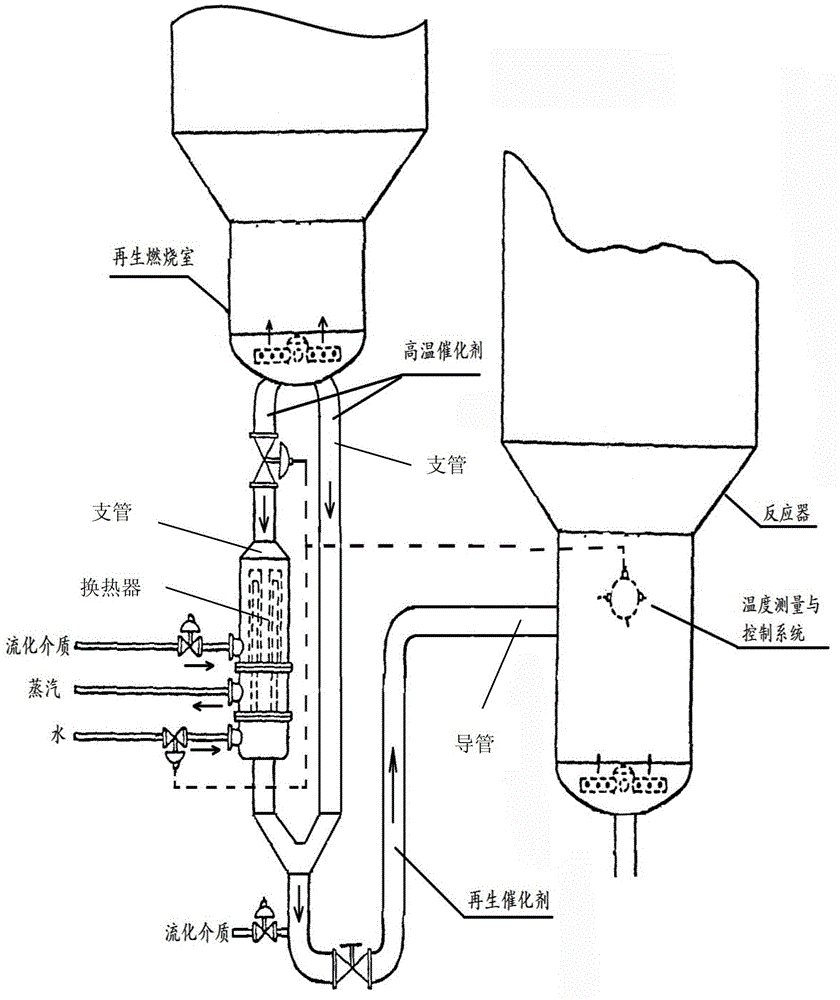

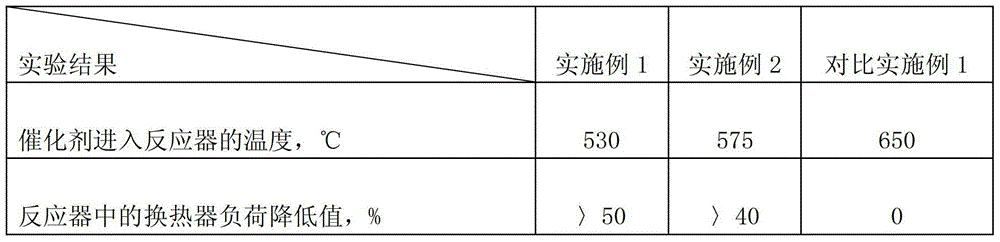

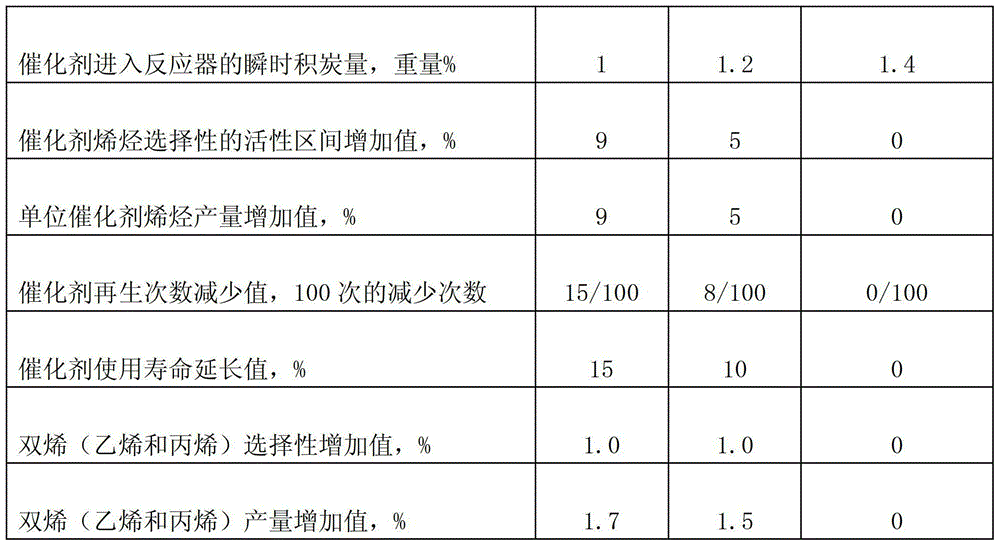

[0051] use figure 1 The system shown performs a methanol-to-olefins (MTO) conversion reaction in which the return of the regenerated catalyst to the reaction is controlled by adjusting the flow ratio of the high temperature regenerated catalyst into two vertical legs in the lower part of the regenerator (regenerated combustor) temperature in the container.

[0052] Open the catalyst flow control valve on the branch pipe with a partitioned heat exchanger inside, so that part of the high-temperature regenerated catalyst flowing out of the regenerator (regeneration combustion chamber) flows into the branch pipe with a partitioned heat exchanger inside, and is transferred by the partitioned wall The heat exchanger cools this part of the high temperature regenerated catalyst.

[0053] The temperature of this part of the high-temperature regenerated catalyst cooled by the partition wall heat exchanger is reduced from 650 ° C to about 400 ° C, and the amount of this part of the cata...

Embodiment 2

[0057] use figure 1 The system shown performs methanol (MTO) to olefins conversion reaction, where the temperature at which the regenerated catalyst is returned to the reactor is controlled by adjusting the heat exchange duty of the dividing wall heat exchanger arranged in the above branch.

[0058] Open the catalyst flow control valve on the branch pipe with a partitioned heat exchanger inside, so that part of the high-temperature regenerated catalyst flowing out of the regenerator (regeneration combustion chamber) flows into the branch pipe with a partitioned heat exchanger inside, and is transferred by the partitioned wall The heat exchanger cools this part of the high temperature regenerated catalyst.

[0059] Adjust the flow rate of the cooling medium in the partition heat exchanger, and gradually increase the cooling load, so that part of the high-temperature regenerated catalyst from the regenerator (regeneration combustion chamber) is cooled in the partition heat excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com