MWW type molecular sieve carrier catalyst and preparation method and application thereof

A molecular sieve and catalyst technology, which is applied in the field of modified molecular sieve catalysts, can solve problems such as easily damaged structures, poor catalyst stability, and catalysts that cannot meet industrial requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

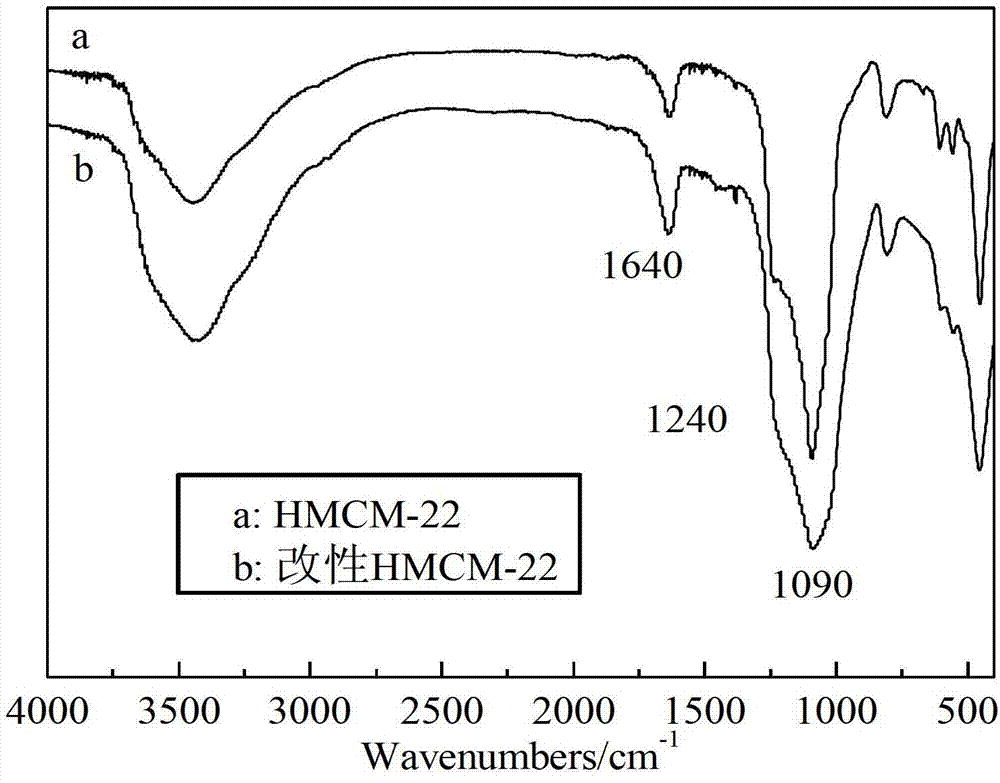

[0038] (a) Take 15 grams of SiO 2 / A1 2 o 3 MCM-22 molecular sieves with a molar ratio of 15 were exchanged into NH by immersing in 20 ml of 0.1 mol / L ammonium nitrate solution at 85°C for 8 hours 4 type molecular sieve, and then calcined at 550°C for 4 hours to obtain H type MCM-22 molecular sieve.

[0039] (b) The H-type MCM-22 molecular sieve prepared in step (a) is exchanged with 20 milliliters of 5mol / L alkaline earth metal magnesium nitric acid solution as the exchange liquid, and is exchanged 3 times at 85° C. according to the solid-to-liquid ratio of 10. The exchange time is 2 hours. After washing, suction filtration, the filter cake was dried at 110° C. for 4 hours. The molecular sieve was calcined at 550°C for 4 hours to obtain Mg-MCM-22 type molecular sieve.

[0040] (c) Mg-modified MCM-22 molecular sieve was impregnated with 0.1mol / L boric acid solution at 25°C for 6 hours, dried at 120°C for 8 hours, and calcined at 550°C for 3 hours to obtain boric acid and ...

Embodiment 2

[0043] (a) Take 15 grams of SiO 2 / A1 2 o 3 MCM-22 molecular sieves with a molar ratio of 50 were exchanged into NH by immersing in 20 ml of 0.1 mol / L ammonium nitrate solution at 85°C for 8 hours 4 type molecular sieve, and then calcined at 550°C for 4 hours to obtain H type MCM-22 molecular sieve.

[0044] (b) The H-type MCM-22 molecular sieve prepared in step (a) is exchanged with 20 milliliters of 5mol / L alkaline earth metal magnesium nitric acid solution as the exchange liquid, and is exchanged 3 times at 85° C. according to the solid-to-liquid ratio of 10. The exchange time is 2 hours. After washing, suction filtration, the filter cake was dried at 110° C. for 4 hours. The molecular sieve was calcined at 550°C for 4 hours to obtain Mg-MCM-22 type molecular sieve.

[0045] (c) Mg-modified MCM-22 molecular sieve was impregnated with 0.1mol / L boric acid solution at 25°C for 6 hours, dried at 120°C for 8 hours, and calcined at 550°C for 3 hours to obtain boric acid and ...

Embodiment 3

[0048] (a) Take 15 grams of SiO 2 / A1 2 o 3 MCM-49 molecular sieves with a molar ratio of 13 were exchanged into NH by immersing in 20 ml of 5 mol / L ammonium nitrate solution at 60°C for 8 hours 4 type molecular sieve, and then calcined at 400°C for 4 hours to obtain H type MCM-49 molecular sieve.

[0049] (b) Exchange the H-type MCM-49 molecular sieve prepared in step (a) with 20 milliliters of 0.1mol / L calcium acetate solution as the exchange solution, and exchange it three times at 60°C according to the solid-to-liquid ratio of 10, each exchange The time is 2 hours. After washing, suction filtration, the filter cake was dried at 110° C. for 4 hours. The molecular sieve was calcined at 400°C for 4 hours to obtain Ca-MCM-49 molecular sieve.

[0050] (c) Ca-modified MCM-49 molecular sieve was impregnated with 1mol / L boric acid solution at 25°C for 6 hours, dried at 120°C for 8 hours, and calcined at 400°C for 3 hours to obtain boric acid and alkaline earth metal modified ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com