Preparation method of hydrogenation catalyst and method for preparing dimethylaminopropylamine diisopropanol

A technology of dimethylaminopropylamine diisopropanol and hydrogenation catalyst is applied in the preparation of organic compounds, molecular sieve catalysts, chemical instruments and methods, etc., and can solve relatively high safety requirements, unknown product purity, and low yield of main products. and other problems, to achieve the effects of good economy, improved activity and stability, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

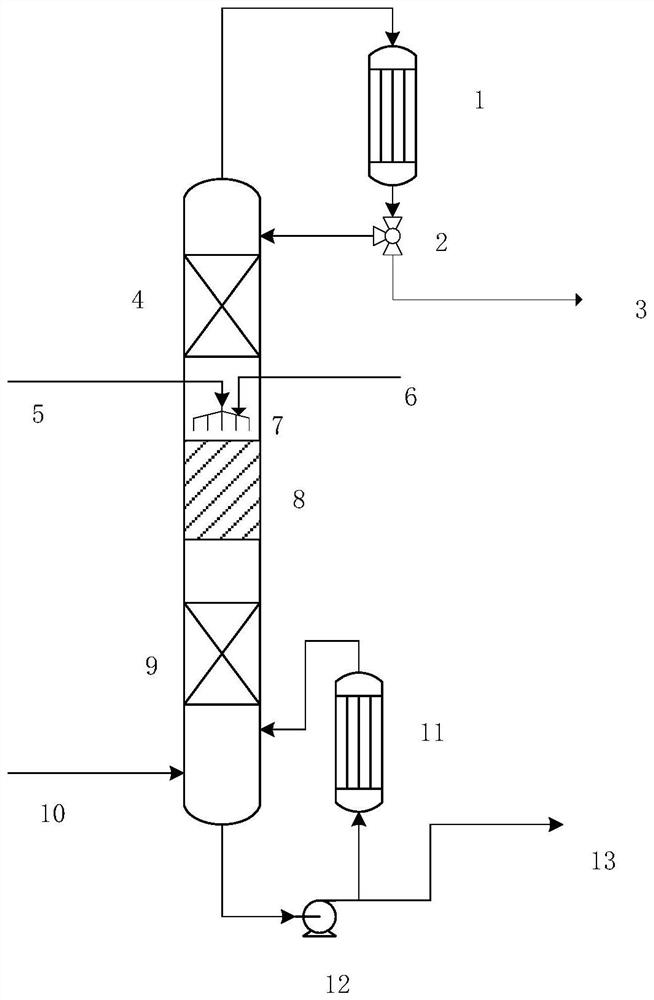

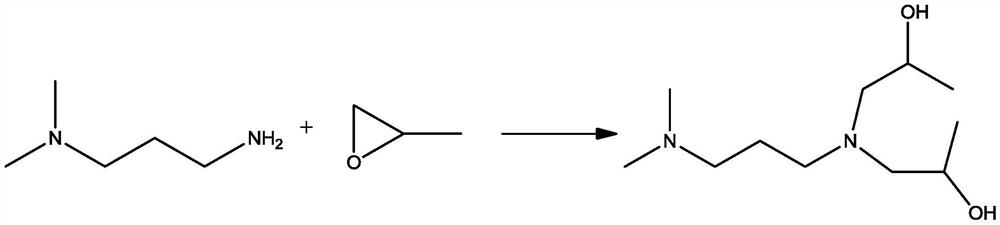

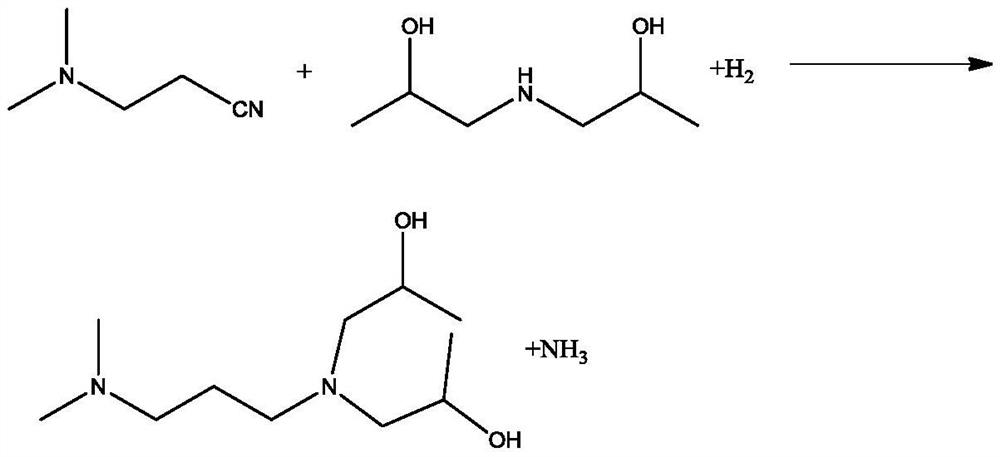

Method used

Image

Examples

Embodiment 1

[0062] 1# Catalyst precursor preparation:

[0063] To 90g HZSM-5 (silicon-aluminum ratio is 200) and 10g ZrSi 2 Add 2g of citric acid, 2g of methyl cellulose and 1g of kale powder, mix evenly, add 10g of deionized water and knead evenly, extrude the block into a cylindrical shape with an extruder, and dry it at 110°C after natural air drying 6h, roasted at 450°C for 6h to get 90%HZSM-5+10%ZrSi 2 Composite carrier.

[0064] Use 100ml of deionized water to prepare an impregnating solution containing 20g of nickel, 2g of ruthenium, and 0.5g of zinc nitrate, and add 77.5g of the above-mentioned composite carrier by equal volume impregnation method. After 24h, the adsorption equilibrium is reached, and then dried at 110°C for 6h, and then dried at 500°C Calcined at the bottom for 8h to obtain 1# catalyst precursor, its mass composition is: 20%Ni+2%Ru+0.5%Zn / 90%HZSM-5+10%ZrSi 2 .

[0065] Synthesis of dimethylaminopropylamine diisopropanol:

[0066] In a stainless steel catalyt...

Embodiment 2

[0069] 2# Catalyst precursor preparation:

[0070] To 95g HZSM-5 (silicon-aluminum ratio is 100) and 5g ZrSi 2 Add 1g of nitric acid, 4g of polyvinyl alcohol and 5g of graphite to the mixture, mix well, add 10g of deionized water and knead evenly, extrude the block into a clover shape with an extruder, and dry it naturally at 100°C for 8h, then at 300°C Roast for 12 hours to get 95% HZSM-5+5% ZrSi 2 Composite carrier.

[0071] Use 100ml of deionized water to prepare an impregnation solution containing 15g of nickel, 0.3g of chromium, and 0.2g of iron nitrate, and add 84.5g of the above-mentioned composite carrier by the equal volume impregnation method. After 24h, the adsorption balance is reached, and then dried at 100°C for 8h, 400 Calcined at ℃ for 10h to obtain 2# catalyst precursor, its mass composition is: 15%Ni+0.3%Cr+0.2%Fe / 95%HZSM-5+5%ZrSi 2 .

[0072] Synthesis of dimethylaminopropylamine diisopropanol:

[0073] In a stainless steel catalytic rectification tower...

Embodiment 3

[0076] 3# Catalyst precursor preparation:

[0077] To 88g HZSM-5 (silicon-aluminum ratio is 400) and 12g ZrSi 2 Add 4g of boric acid, 1g of soluble starch and 3g of scallop powder, mix evenly, add 20g of deionized water and knead evenly, extrude the block into a cross core shape with an extruder, and dry it naturally at 80°C for 12h. Calcined at 500°C for 8h to get 88%HZSM-5+12%ZrSi 2 Composite carrier.

[0078] Use 100ml of deionized water to prepare an impregnation solution containing 10g of nickel, 2.0g of chromium, and 1.0g of zinc nitrate, and add 87.0g of the above-mentioned composite carrier by equal volume impregnation method. After 24h, the adsorption balance is reached, and then dried at 80°C for 12h, 600 Calcined at ℃ for 6h to obtain 3# catalyst precursor, its mass composition is: 10%Ni+2%Cr+1%Zn / 88%HZSM-5+12%ZrSi 2 .

[0079] Synthesis of dimethylaminopropylamine diisopropanol:

[0080]In a stainless steel catalytic rectification tower with an internal diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com