A new type of soil heavy metal fixative and its preparation method and application

A fixative and heavy metal technology, applied in the field of soil remediation, can solve problems such as poor fixation effect, short lasting passivation time, and large soil disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0114] The present invention also provides a kind of preparation method of described fixing agent, comprises the steps:

[0115] (1) Provide component A and component B, wherein,

[0116] Component A is biomass power plant ash particles;

[0117] Component B is phosphate;

[0118] (2) under stirring conditions, adding the component B into water to obtain a phosphate solution;

[0119] (3) under stirring conditions, the component A is mixed with the phosphate solution obtained in step (2) to obtain the first mixed solution;

[0120] (4) Treating the first mixed solution obtained in step (3) at a certain temperature to obtain the fixative.

[0121] In another preferred example, the step (4) is carried out under airtight conditions.

[0122] In another preference, the step (4) includes:

[0123] (4-1) Seal the first mixed solution obtained in step (3) in the inner tank of the autoclave, and heat it to the first treatment temperature to obtain the fixative.

[0124] (4-2) He...

Embodiment 1

[0155] Embodiment 1 Fixative 1

[0156] Dissolve 2 g of disodium hydrogen phosphate powder in 80 mL of aqueous solution, add 10 g of biomass power plant ash into the disodium hydrogen phosphate solution under stirring conditions, and stir well. Pour the mixed solution into a 100mL autoclave liner (the maximum pressure of the laboratory hydrothermal kettle is generally 3MpaG, and the maximum filling degree is generally ≤ 80%, that is, 80mL liquid, which can be guaranteed under the safe pressure of the kettle in this embodiment), and seal , placed in an electric oven and heated at 180°C for 10 hours, filtered and washed the residue in the kettle after the reaction, and dried at 40°C to obtain Fixative 1.

[0157] result

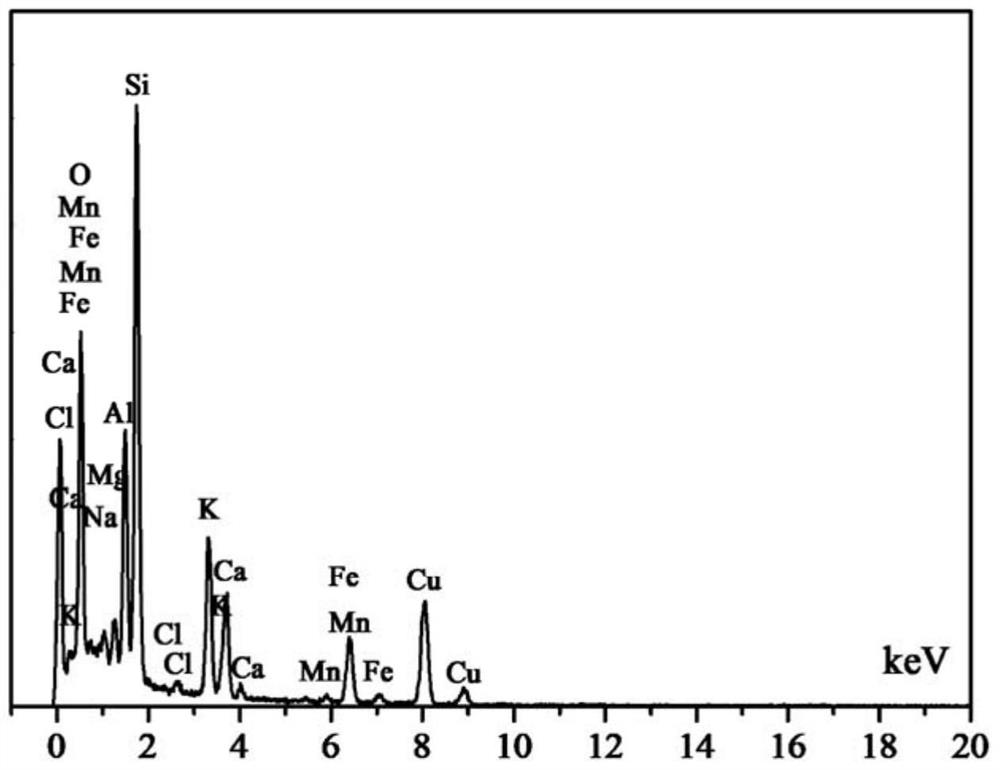

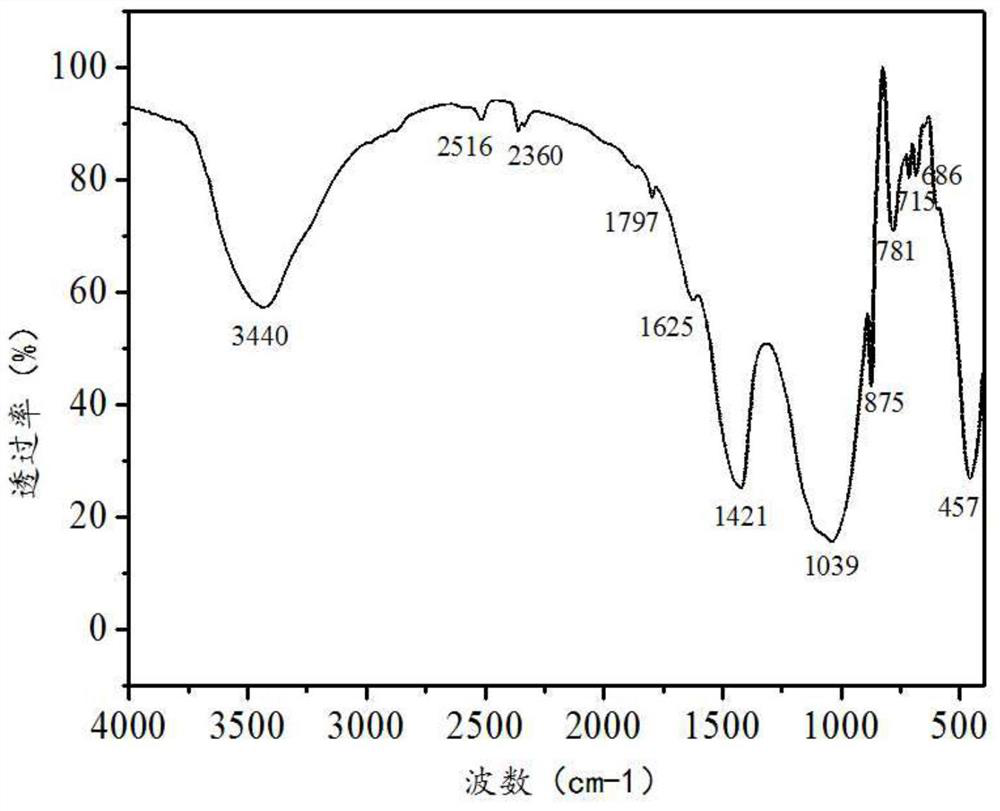

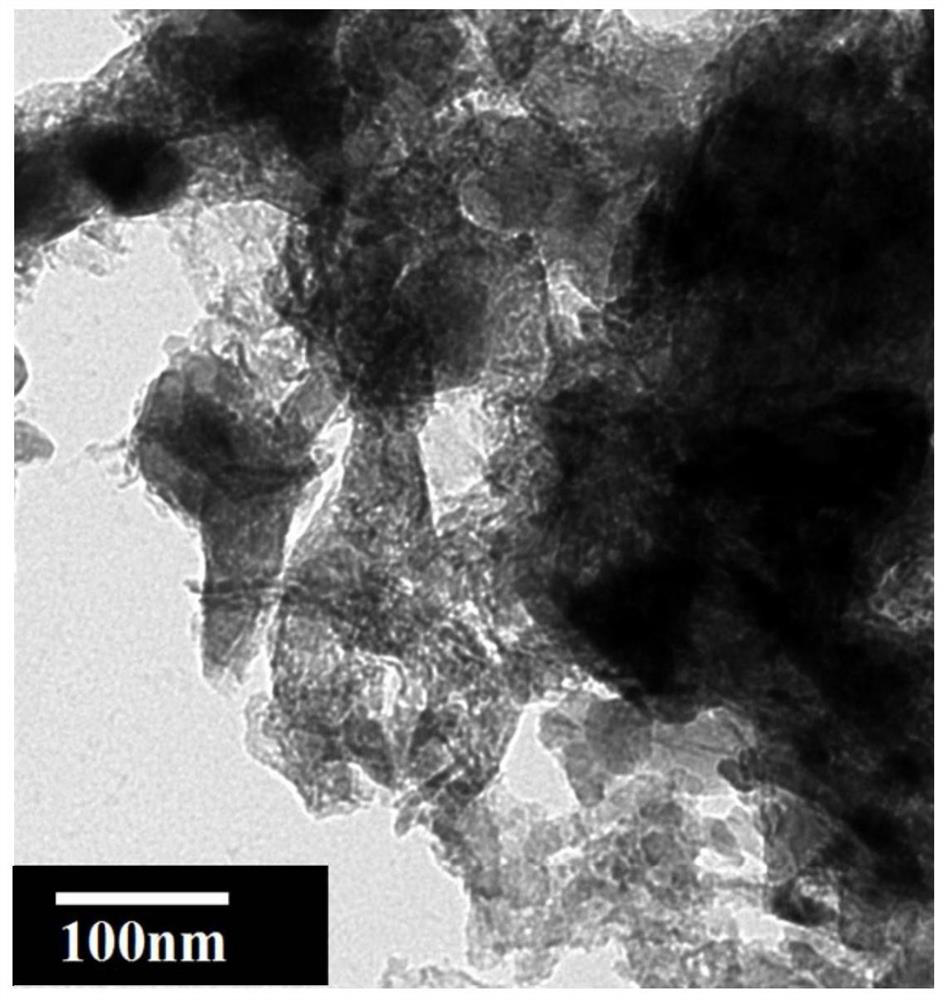

[0158] Conduct EDS, FT-IR, TEM and XRD tests on the biomass power plant ash used.

[0159] FT-IR, TEM and XRD tests were carried out on the obtained fixative.

[0160]figure 1 It is the EDS collection of illustrative plates of the biomass power plant ash use...

Embodiment 2

[0167] Embodiment 2 Fixative 2

[0168] Same as Example 1, except that disodium hydrogen phosphate is replaced by dipotassium hydrogen phosphate to obtain fixative 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com