High-dispersion dual-functional catalyst for hydrogenating and deoxidizing phenol and preparation method of catalyst

A dual-function catalyst and hydrodeoxygenation technology, which is applied in hydrogenation preparation, molecular sieve catalyst, carbon-based compound preparation, etc., can solve problems such as uneven distribution of functional groups, irregular material channels, uneven metal dispersion, etc., and achieve uniform distribution of functional groups , low cost, uniform distribution of active components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 4.00 g (0.69 mmol) of Pluronic P123 was dissolved in 150 mL of 0.03 mol / L HCl solution at room temperature, heated to 40 °C with stirring, and then tetraethylorthosilicate TEOS (9.00 g, 43.20 mmol) was added. TEOS was prehydrolyzed for 2 hours and then 143 μL (0.7652 mmol) of mercaptopropyltrimethoxysilane (MPTMS) and 0.0299 g (0.1530 mmol) of chloroplatinic acid (H 2 PtCl 60.01 g Pt / mL solution) and 1.2605 g (6.171 mmol) of aluminum isopropoxide (AIP). The resulting mixture was stirred at 40 °C for 24 h and then left to age at 100 °C for 24 h. The obtained solid material was filtered, dried at 100 °C for 8 h, and finally calcined in an air atmosphere in a muffle furnace, heated to 500 °C at a heating rate of 2 °C / min, then kept at 500 °C for 6 h, and cooled to room temperature to obtain a solid. Metal active and acidic bifunctional catalyst 1%Pt-(SH) / Al-SBA-15(7).

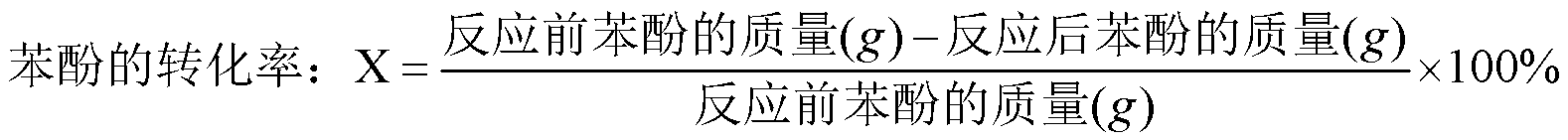

[0033] The activity evaluation reaction is to dissolve 1.1764 g (0.0125 mol) phenol in 25.0 mL of dic...

Embodiment 2

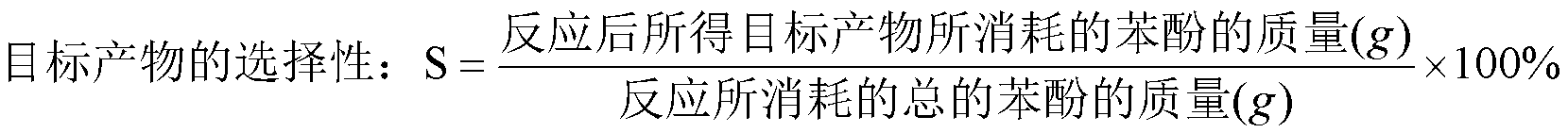

[0035] The catalyst was prepared according to the method of Example 1 to obtain a 1% Pt-(SH) / Al-SBA-15(7) catalyst. The other activity evaluation conditions were the same as in Example 1 except for the solvent. Take water, ethanol and toluene as solvent to do three groups of reactions respectively, and the results are shown in Table 1.

Embodiment 3

[0037] The catalyst was prepared according to the method of Example 1 to obtain a 1% Pt-(SH) / Al-SBA-15(7) catalyst. Three groups of reactions were performed under the conditions of reaction temperatures of 30°C, 50°C and 100°C, respectively, and other activity evaluation conditions were the same as those in Example 1 except for the reaction temperature conditions. The results are shown in Table 2 (for the convenience of comparison, the reaction at 180° C. is also listed in Table 2).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com