Continuous preparation method of hydrogenated bisphenol A

A technology for hydrogenating bisphenol and bisphenol, which is applied in hydrogenation preparation, separation/purification of hydroxyl compounds, organic chemistry, etc. The process is simple and the effect of improving application performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

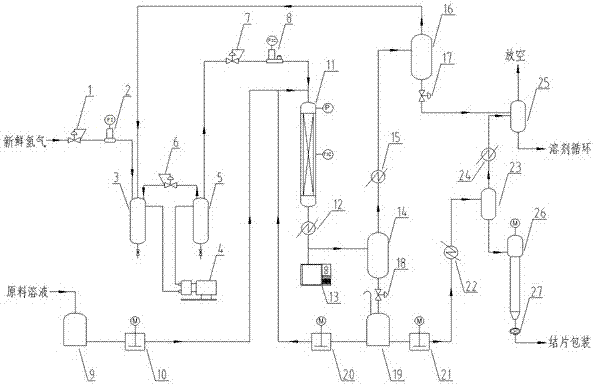

[0022] A kind of continuous preparation method of hydrogenated bisphenol A of the present invention, it comprises the steps:

[0023] First, the bisphenol A raw material is prepared into a solution with a certain concentration and stored in the raw material tank 9 , and then mixed with hydrogen gas at the inlet of the tube reactor 11 after being boosted by the metering pump 10 . Fresh hydrogen passes through the pressure stabilizing valve 1 to maintain a stable pressure, and then enters the inlet buffer tank 3 after being measured by the flow meter 2, and enters the outlet buffer tank 5 after being boosted by the hydrogen circulation compressor 4, and the outlet buffer tank is controlled by the back pressure valve 6 5 pressure, the hydrogen is discharged from the top of the outlet buffer tank 5, the pressure is controlled by the pressure stabilizing valve 7, and the flow rate passed by the flow controller 8 is controlled, and then mixed with the boosted bisphenol A raw material...

Embodiment 1~22

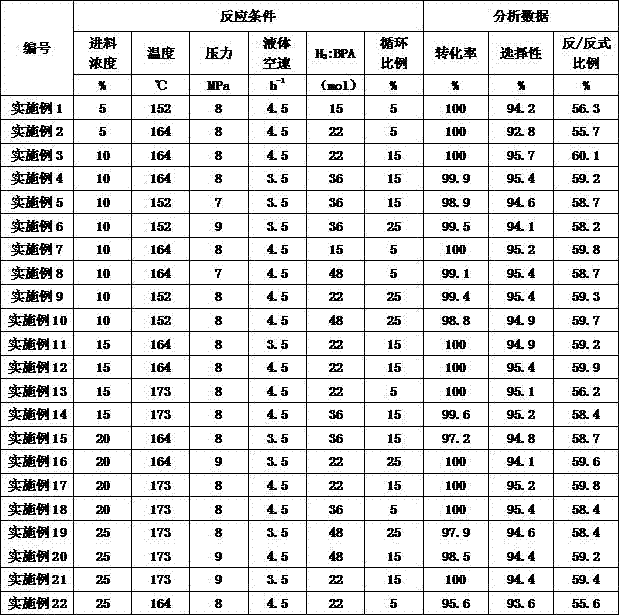

[0038] Carry out the filling and hydrogenation reaction of catalyst according to the above-mentioned implementation method, carry out the hydrogenation reaction effect investigation under different process conditions, wherein each condition is stable for more than 24 hours, take the hydrogenation product solution analysis result of condenser 12 outlet as investigation basis, The ratio of catalyst bed height to pipe diameter is 8:1, and the specific implementation conditions and hydrogenation product analysis data are shown in Table 1:

[0039] Table 1 Hydrogenation reaction conditions and analysis data table

[0040]

Embodiment 23~34

[0042] Carry out hydrogenation reaction according to the processing condition of embodiment 3 in the above-mentioned implementation method, and investigate the process of hydrogenation reaction product normal pressure desolvation, decompression by-product, investigate the removal effect of solvent and by-product under different processing conditions, The hydrogenated bisphenol A product was obtained after the solvent and by-products were removed, and the hydrogenated bisphenol A product was analyzed. The specific implementation conditions and analysis data are shown in Table 2:

[0043] Table 2 Desolvation, by-product conditions and product analysis data table

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com