A kind of upward slurry column method grouting and top filling method

A technology for grouting and grouting holes, which is applied in the direction of filling, earthwork drilling, mining equipment, etc. It can solve the problems of increased drilling depth, inability to grout, and poor surface control, so as to improve production efficiency and save drilling Effect of Hole Cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

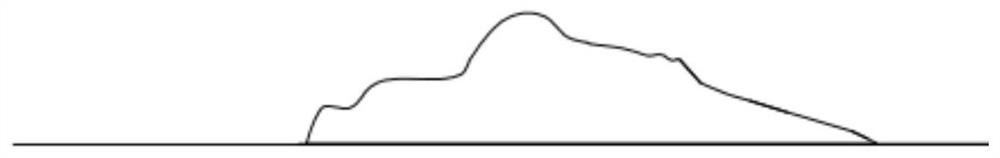

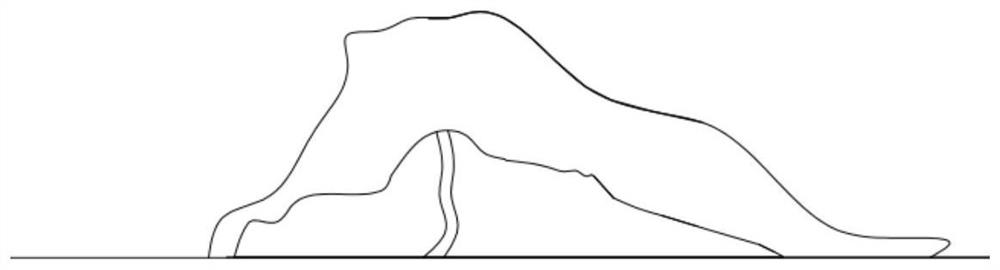

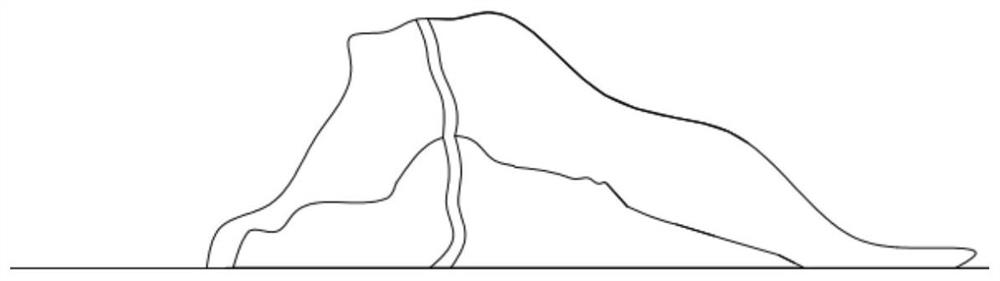

Image

Examples

Embodiment 1

[0043] The present invention provides an upward grouting column grouting filling method, the specific operation is as follows:

[0044] Step 1: Feeding the paste. Drill holes with an inner diameter of 150-175mm are arranged outside the production stop line, and the filling paste is mixed on the surface and then transported to the bottom drainage roadway by the pipeline. Downhole transportation. The filling pipeline is divided into three in the bottom pumping road, and enters the upper bottom pumping road, the middle bottom pumping road and the lower bottom pumping road respectively. Bottom pumping roadway reinforcement. Temporary reinforcement of the bottom pumping roadway shall be carried out within 30m behind the working face.

[0045] Step 2: Drain the hole through the hole. On the basis of the original extraction hole, the through-hole operation is carried out at 20m-30m behind the working face, and a 75-100mm high-pressure and high-wear filling pipe is buried to the u...

Embodiment 2

[0068] The specific filling method of the present embodiment is as follows:

[0069] Filling for the first time: grouting filling for coal seam floor, adding retarder in the last 10 minutes.

[0070] Second filling: continue filling after 15 to 30 minutes to form a secondary filling body, and the filling height will gradually increase. In the last 10 to 30 minutes, add retarder and reserve channels.

[0071] The third filling: continue filling after 10-30 minutes to reach the top filling. Add retarder in the last 10-30 minutes to create conditions for later grouting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com