Activated carbon desorption method of activated carbon tank in benzene vapor recovery unit

A recovery device and activated carbon technology, applied in separation methods, chemical instruments and methods, combustible gas purification, etc., can solve problems such as difficult desorption, reduce the average vacuum degree, improve the circulation processing capacity, and reduce the time required for startup Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

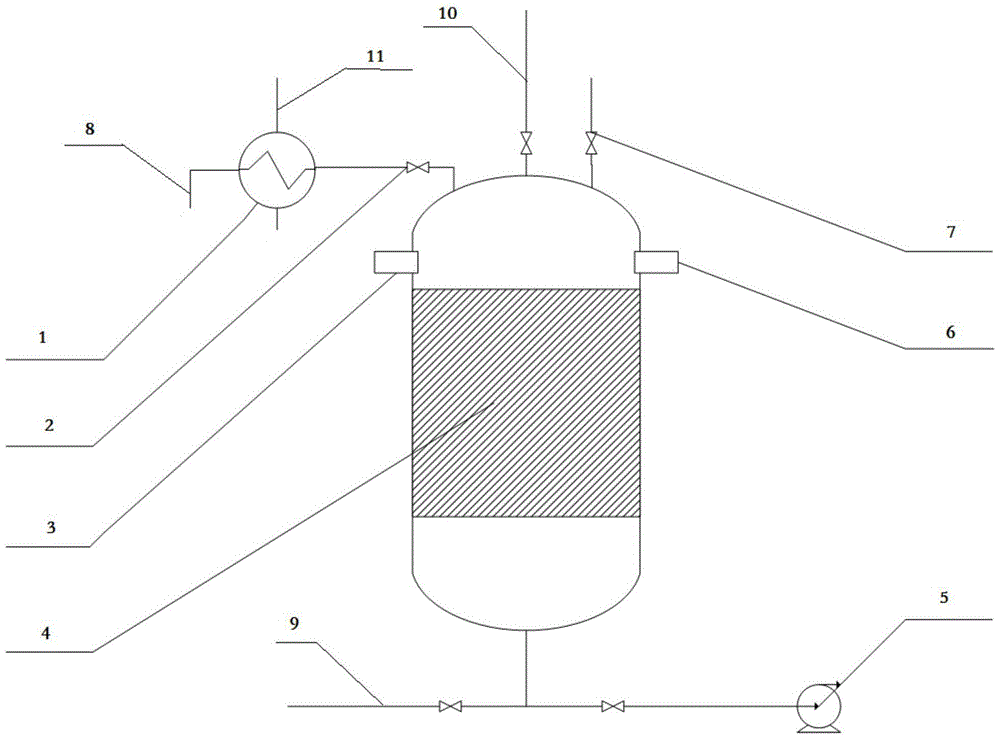

[0018] With design processing capacity of 300Nm 3 / h benzene vapor recovery device as an example, the adsorption tank is a pressure tank with a diameter of 1.6 meters, and 2 tons of activated carbon is installed inside.

[0019] (1) The air purge inlet pipeline and the steam heat tracing pipeline on the top of the activated carbon tank 4 are heat exchanged through the heat exchanger 1, and the temperature of the purge inlet air can be read by the temperature indicator 3 in the upper space of the activated carbon tank 4. The heat transfer rate of the heat exchanger was controlled to control the purge air temperature at 55°C.

[0020] (2) After the activated carbon tank 4 is adsorbed and saturated, its activated carbon bed is regenerated by the vacuum provided by the vacuum pump 5. When the pressure in the tank drops below 5.0kPa, open the purge solenoid valve 2 of the air inlet on the top of the activated carbon tank, and introduce the The heated clean air enters the activated...

Embodiment 2

[0025] According to the conditions and steps described in Example 1, the temperature of the purge air is only controlled at 40°C by controlling the heat transfer rate of the heat exchanger. After the purge solenoid valve 2 is opened for 1.5 minutes, the purge solenoid valve 2 is closed to make the inside of the tank The vacuum degree drops further and is maintained for 1.5 minutes before opening the purge solenoid valve 2.

[0026] The comparison test shows that after the warming air is introduced, the time required for the desorption of the activated carbon tank is reduced from 15 minutes to 12 minutes, and at the same time the desorption of the activated carbon tank is complete, and the adsorption capacity of benzene increases by about 5%.

Embodiment 3

[0028] According to the conditions and steps described in the embodiment, the temperature of the purge air is controlled at 60°C only by controlling the heat transfer rate of the heat exchanger. After the purge solenoid valve 2 is opened for 1 minute, the purge solenoid valve 2 is closed to make the vacuum in the tank Further down, and maintain 1.5min and then open the purge solenoid valve 2.

[0029] The comparison test shows that after the warming air is introduced, the time required for the desorption of the activated carbon tank is reduced from 15 minutes to 10.5 minutes, and at the same time the desorption of the activated carbon tank is complete, and the adsorption capacity of benzene increases by about 12%.

[0030] Obviously, by introducing heated air for purging, the temperature of the bed layer in the activated carbon tank during desorption and desorption can be increased, benzene crystals at low temperature can be melted, and the desorption speed of benzene molecules...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com