Metal organic framework-silicon based composite material, and preparation method and application thereof

A metal-organic framework and silicon-based composite material technology, which is applied in the field of mass spectrometry and can solve the problems of interfering with the determination of small molecular compounds and low sensitivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

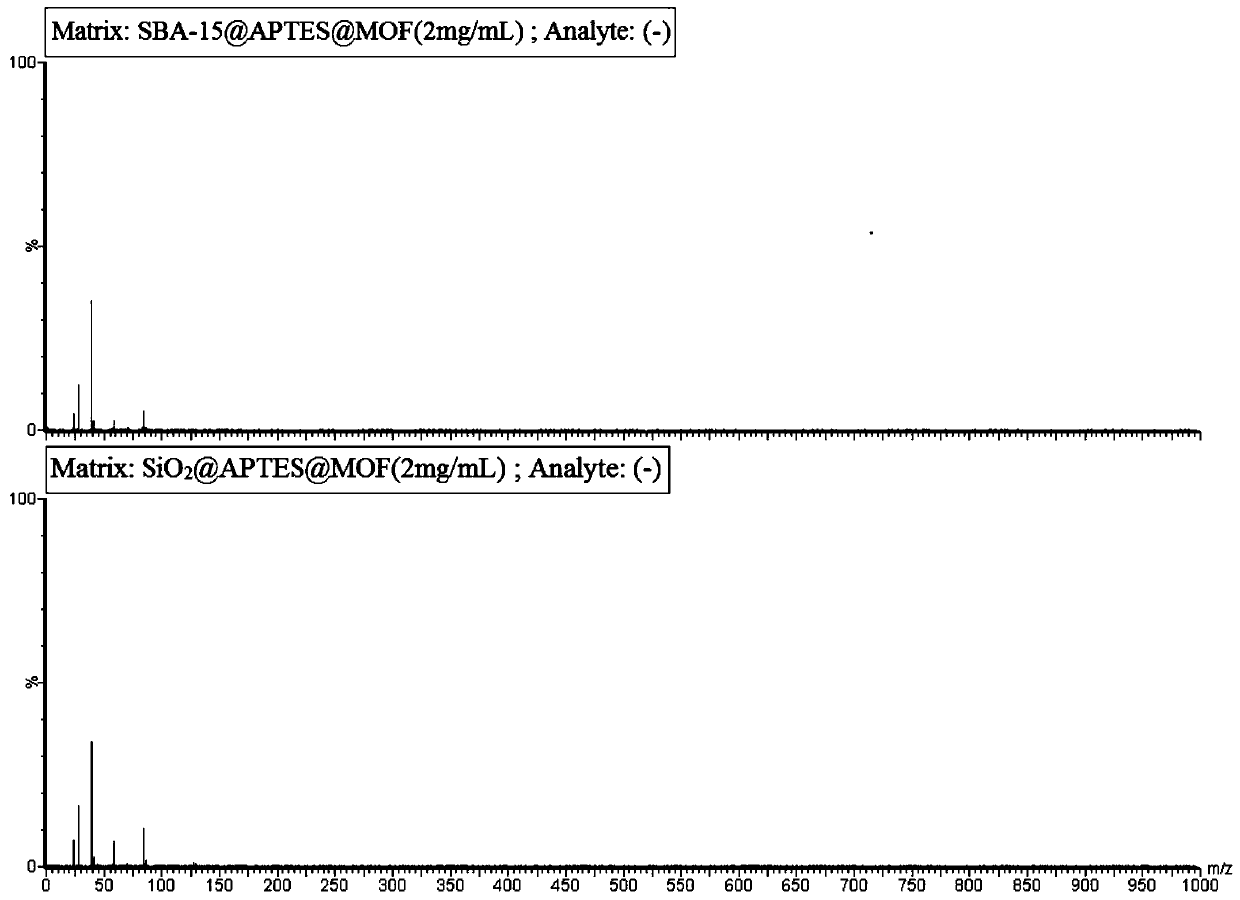

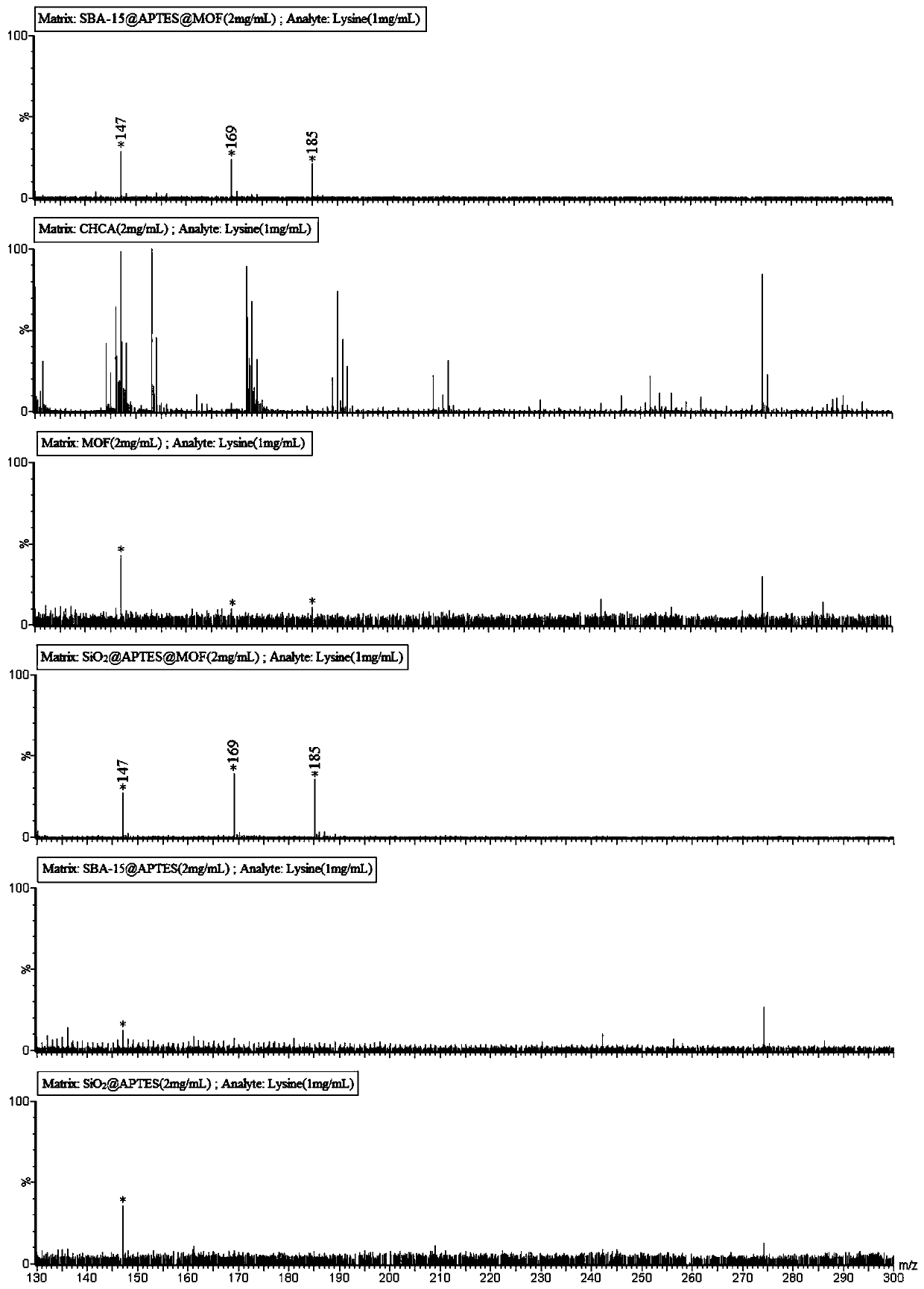

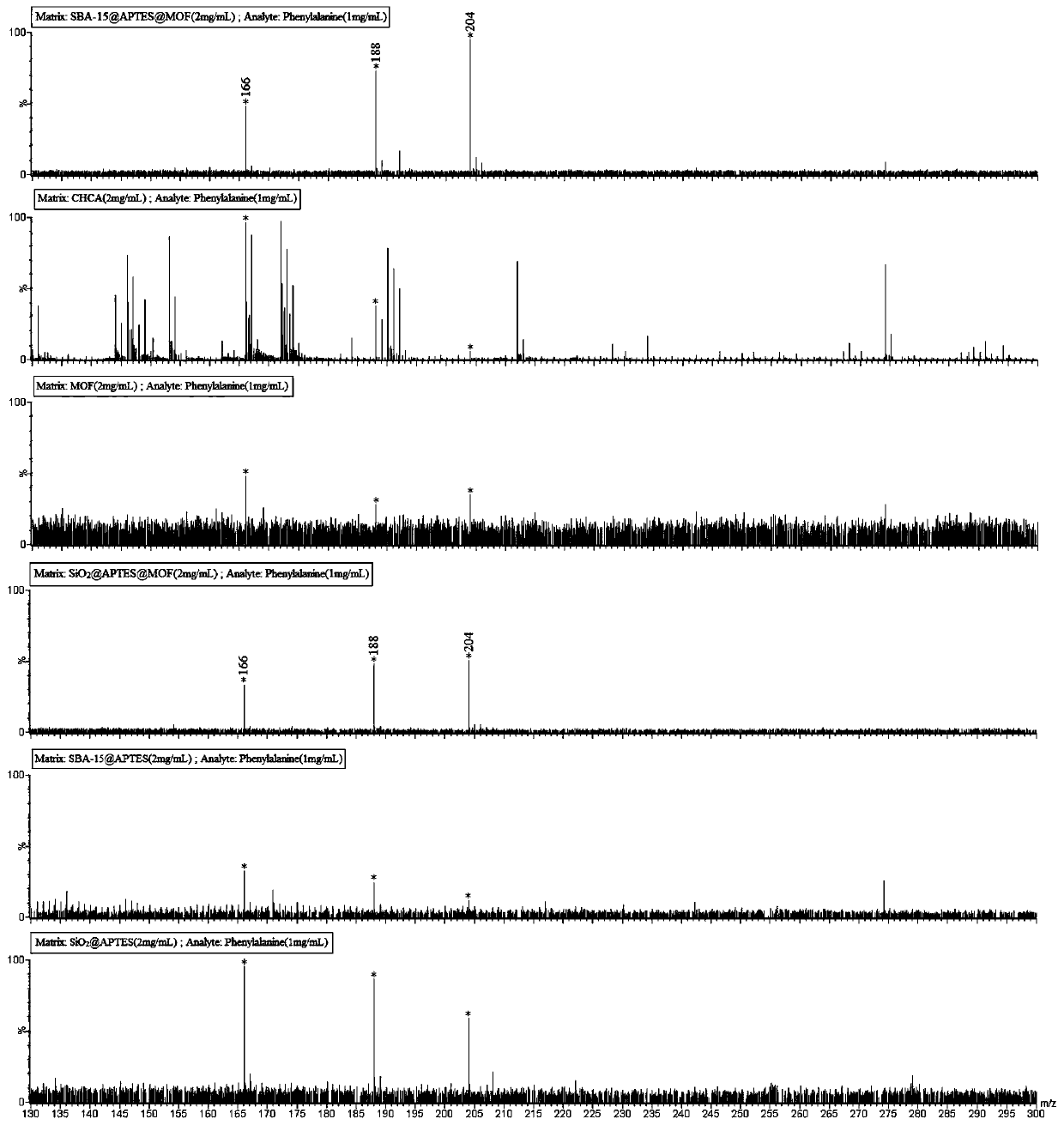

Image

Examples

preparation example Construction

[0047] In the present invention, the preparation method of the siloxane-modified silicon-based material preferably includes the following steps:

[0048] The silicon-based raw material, 3-aminopropyltriethoxysilane and solvent are mixed and then hydrolyzed to obtain the silicon-based material modified by siloxane.

[0049] In the present invention, the surface of the silicon-based raw material is modified with silanol, which can be hydrolyzed with 3-aminopropyltriethoxysilane to obtain a siloxane-modified silicon-based material. In the present invention, the silicon-based raw material preferably includes silica microspheres or SBA-15 mesoporous materials; the particle size of the silica microspheres is preferably 25-100 nm, more preferably 25-50 nm. In the present invention, there is no special limitation on the source of the silicon-based raw material, and commercially available products well known to those skilled in the art can be used. In the present invention, the amount...

Embodiment 1

[0067] (1) Preparation of MOF materials

[0068] 4.63g of Al(NO 3 ) 3 9H 2 O and 2.75 g of 2,5-dimercaptoterephthalic acid were mixed in 30 mL of ultrapure water; the resulting mixture was transferred to a Teflon-lined autoclave reactor, sealed and placed in an oven at React at 150°C for 5 hours; after the reaction is completed, centrifuge the obtained system at 4000rpm for 5min, alternately wash the centrifuged solid material with dimethylformamide (DMF) and absolute ethanol for 4 times, centrifuge at 4000rpm for 5min after each washing, and The solid material obtained after the last centrifugation was dried in a vacuum oven at 120°C for 12 hours to obtain the MOF material.

[0069] (2) Preparation of SBA-15@APTES@MOF

[0070] Ultrasonically disperse 0.5g of SBA-15 mesoporous material and 50mL of absolute ethanol in a beaker and transfer it to a three-necked flask, wash the beaker with 100mL of absolute ethanol, and combine the washings into the three-necked flask; then a...

Embodiment 2

[0073] Only the SBA-15 mesoporous material in Example 1 is replaced by silica microspheres (average particle size is 25nm), and the rest of the operations are carried out according to the method of Example 1, through the prepared MOF material and SiO 2 @APTES, SiO was finally prepared 2 @APTES @MOF.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com