Method for removing liquid-phase benzene retained in catalyst of liquid-phase ethylbenzene alkylation and transalkylation reactor through superheated benzene steam purging

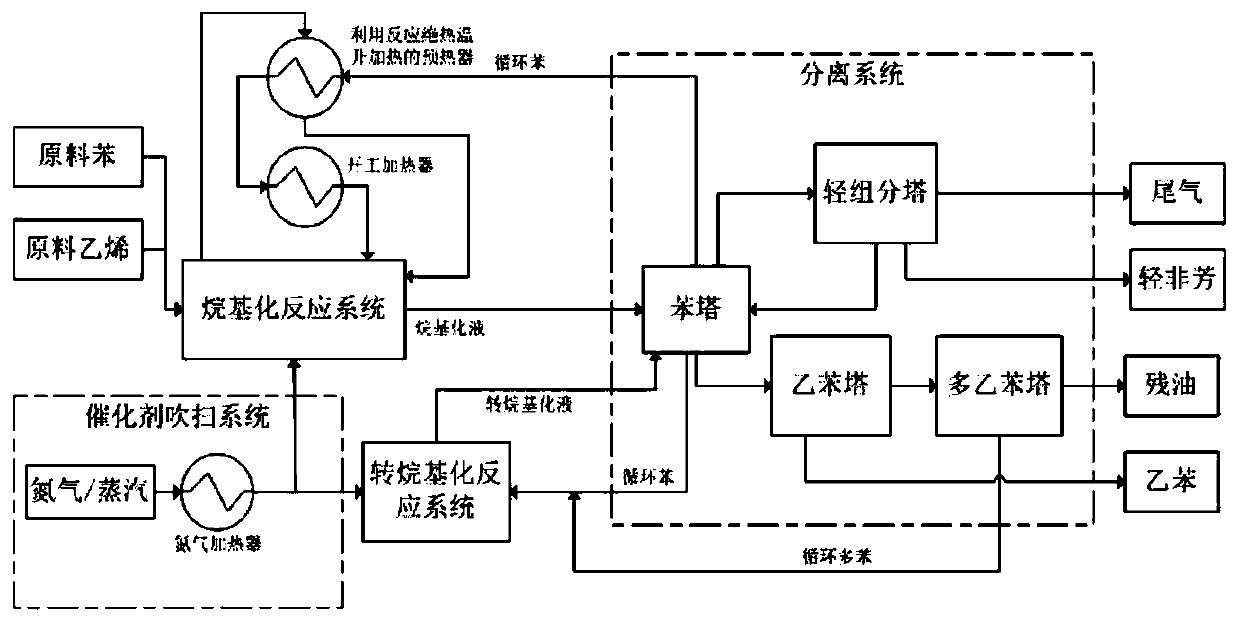

A technology of transalkylation and French ethylbenzene, which is applied in chemical instruments and methods, physical/chemical process catalysts, catalyst regeneration/reactivation, etc., can solve the problem of large investment, land occupation and low construction cost of circulating hot nitrogen system , waste a lot of nitrogen and other problems, to achieve the effect of solving excessive VOC emissions, small investment in equipment costs, and solving excessive investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following examples further illustrate the content of the present invention, but should not be construed as limiting the present invention. Without departing from the essence of the present invention, the modifications and substitutions made to the methods, steps or conditions of the present invention all belong to the scope of the present invention.

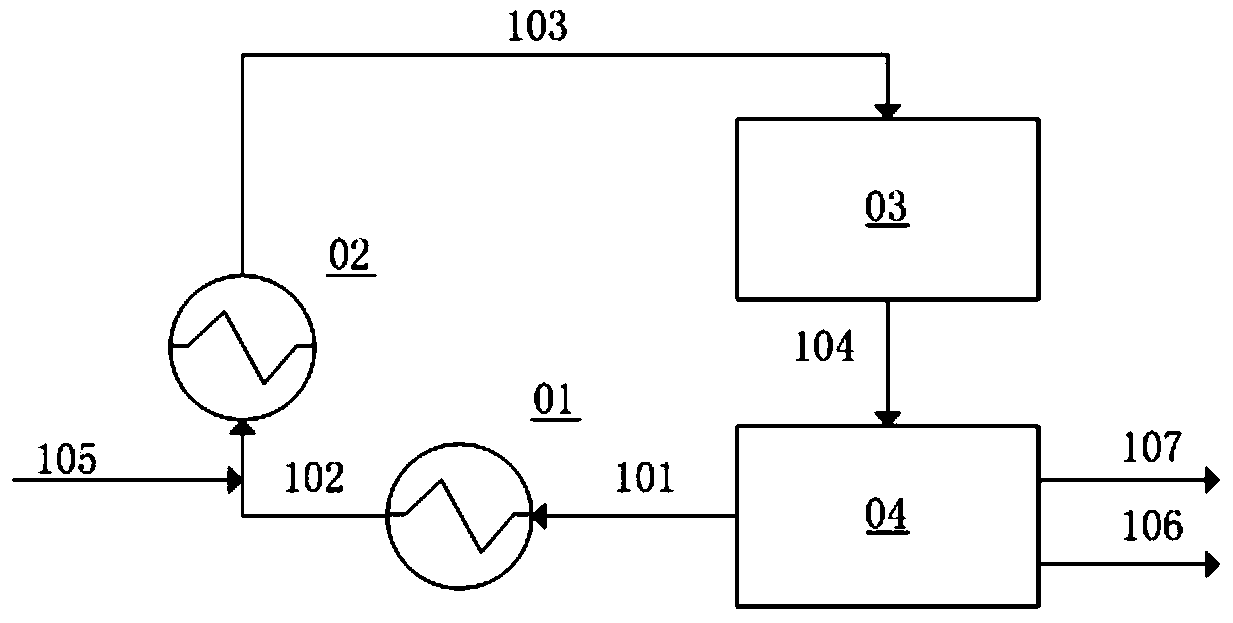

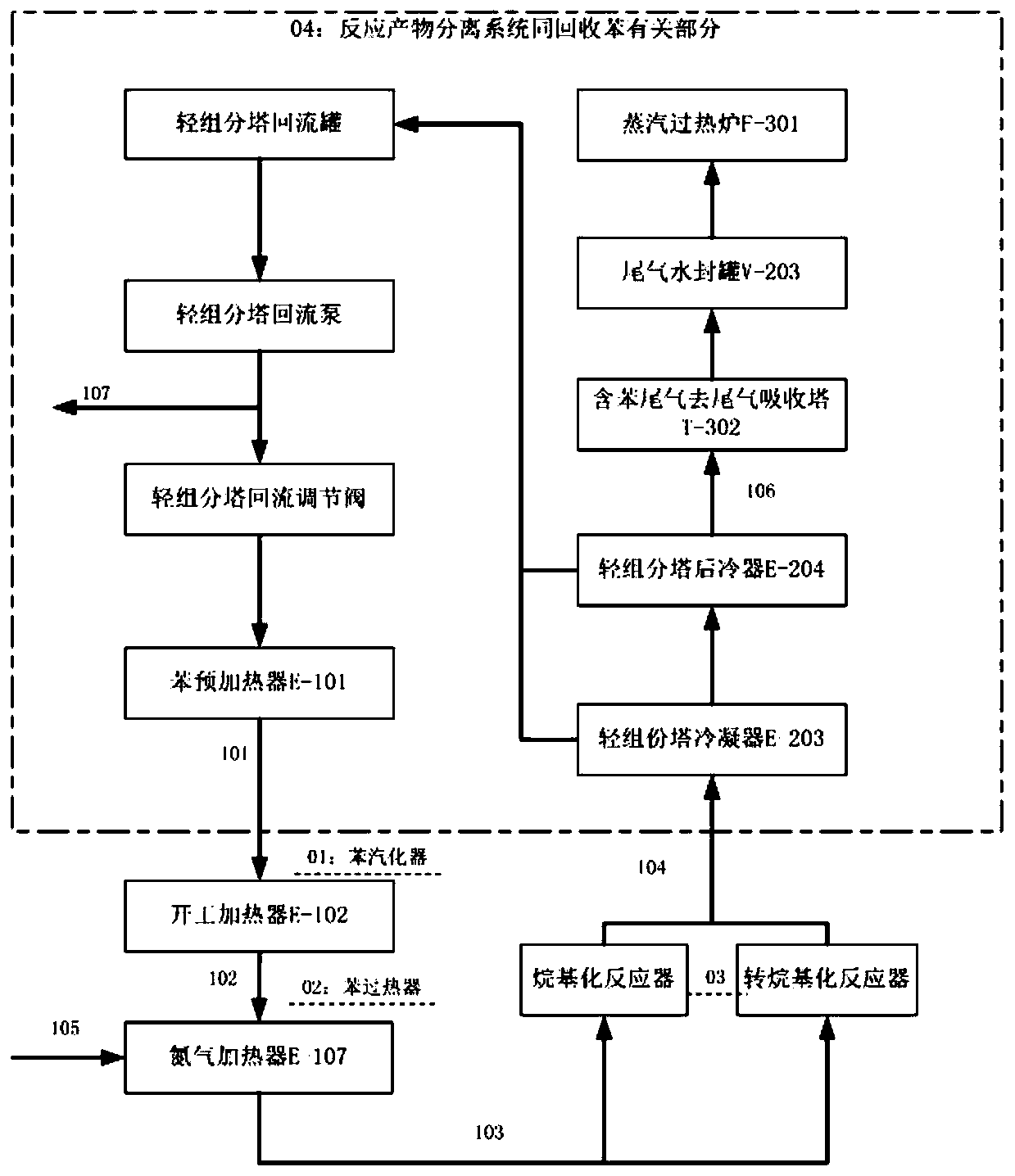

[0039]First, the liquid-phase benzene 101 separated from the reaction product separation system 04 in the liquid-phase ethylbenzene production device is sent to the benzene vaporizer 01, and the liquid-phase benzene 101 is vaporized by a heating heat source into benzene vapor 102, and then superheated by the benzene superheater 02, The superheated benzene vapor 103 is sent to the alkylation reactor or the transalkylation reactor 03, and the sensible heat of the superheated benzene vapor is used to dissipate the liquid-phase benzene gas retained in the alkylation and / or transalkylation catalyst bed Then the vapor phase ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com