Process and device for condensing and cooling crude benzene vapor

A steam condensation and cooling process technology, applied in the field of coal chemical industry, can solve the problems of increasing energy consumption and operating costs, and the increase of low-temperature water consumption, so as to save low-temperature water consumption, reduce equipment investment and land occupation, reduce energy consumption and operation cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

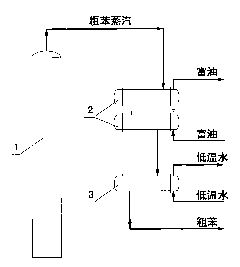

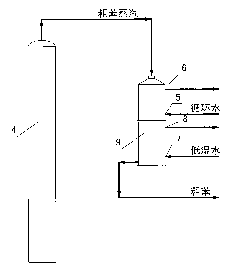

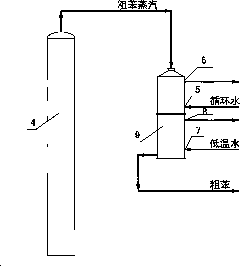

[0014] See figure 2 , crude benzene steam condensation cooling process, the process first uses circulating water as heat exchange medium to exchange heat with the crude benzene steam coming out of the debenzene tower 4, and the crude benzene steam cooled by circulating water is then cooled by low-temperature water.

[0015] The circulating water cooling and cooling water cooling processes are carried out in an equipment condensing cooler.

[0016] Crude benzene steam condensation cooling device 9, the device is a tank structure, the tank body part is divided into two connected areas, the above-mentioned area is a circulating water cooling area, and the side is provided with a circulating water inlet 5 and a circulating water outlet 6; the lower area is In the low-temperature water cooling area, a low-temperature water inlet 7 and a low-temperature water outlet 8 are arranged on the side.

[0017] The inlet temperature of circulating water in the upper area of the device is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com