Waste gas treatment device and system for chemical reaction kettle

A technology for waste gas treatment device and chemical reaction, which is applied in combined devices, chemical/physical/physical-chemical stationary reactors, organic chemistry, etc., can solve the problems of polluted environment and impure benzene, etc., to improve the purity and improve the filtering effect. , the effect of improving the collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

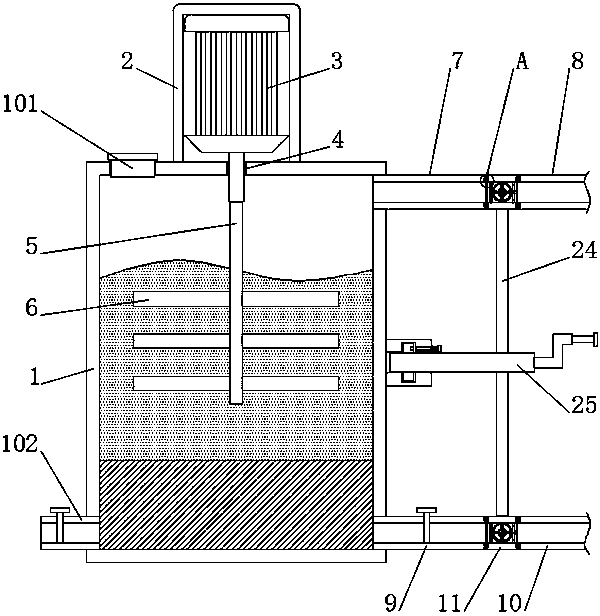

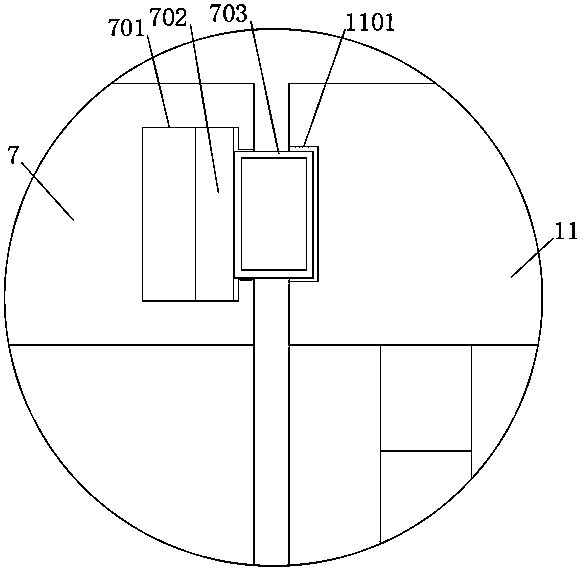

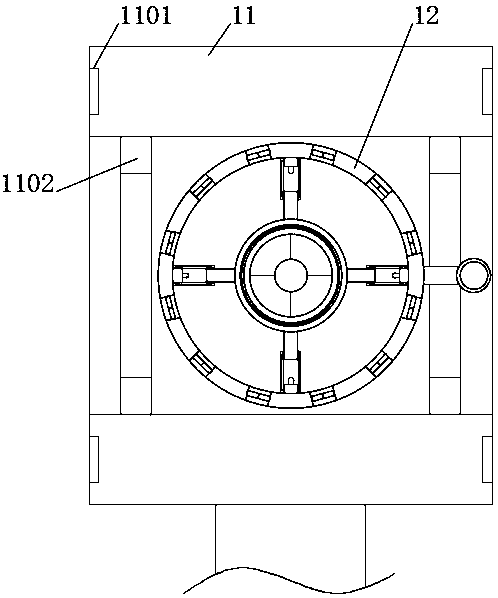

[0035] see Figure 1-4 , a waste gas treatment device for a chemical reactor and its system, comprising a reactor main body 1 filled with a coal tar mixed solution containing benzene, the upper end of the reactor main body 1 is fixedly connected with a control box 2, the control box 2 A motor 3 is fixedly connected inside, and a rotating hole 4 is drilled at the upper end of the main body of the reactor 1. The power output end of the motor 3 runs through the rotating hole 4. The power output end of the motor 3 is fixedly connected with a stirring shaft 5, and the outer end of the stirring shaft 5 is fixedly connected with a A plurality of evenly distributed stirring paddles 6, the outer end of the reactor main body 1 is fixedly connected with a left air guide pipe 7 and a left liquid discharge pipe 9, the left air guide pipe 7 is located on the upper side of the left liquid discharge pipe 9, the left air guide pipe 7 and the left liquid discharge pipe The pipes 9 are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com