High-silicon mordenite and preparation method thereof

A technology of mordenite and high silicon, applied in mordenite crystalline aluminum silicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problem of inability to produce hydrophobic MOR zeolite on an industrial scale, and achieve good microporous adsorption properties and perfect crystal structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0047] 1. Preparation method

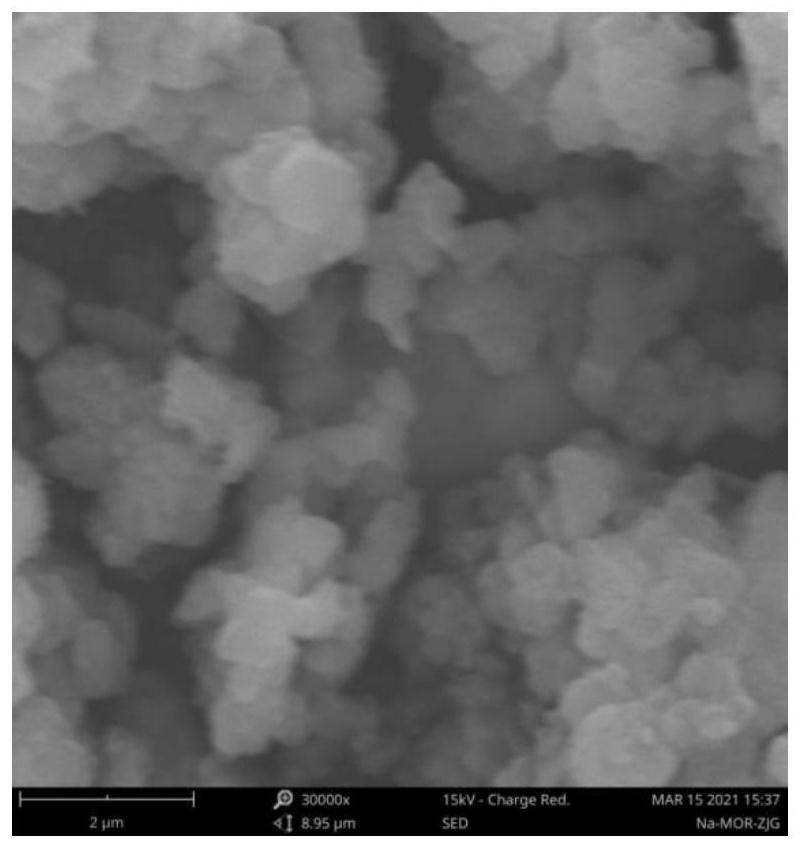

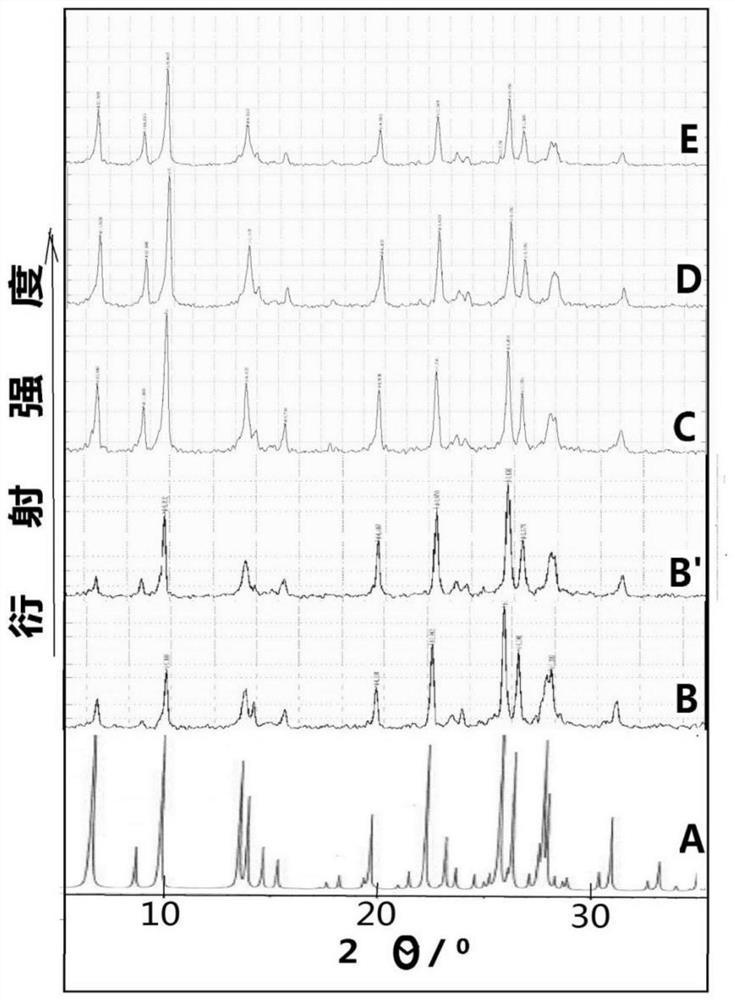

[0048] 1.1. Preparation of H-MOR: Na-MOR was synthesized according to the documented Syntheses of Zeolitic Materials, Second Revised Edition, Edit.By H.Robson, 2001P212. Synthetic raw materials use silica gel as the silicon source, sodium aluminate as the aluminum source, and the molar composition of the reaction mixture formed by mixing sodium hydroxide and water is 6Na 2 O: Al 2 o 3 : 30SiO 2 : 78H 2 O. Stir the reactant evenly and place it in a stainless steel reaction kettle with a capacity of 4 cubic meters, and conduct a hydrothermal reaction at 170° C. for 24 hours under the condition of stirring. After the reaction product was washed and dried, it was ion-exchanged with 1.0M sulfuric acid solution at a liquid / solid ratio of 10 / 1 at a temperature of 90°C for 3 hours, then washed and dried to make H-MOR, which was sample A.

[0049] 1.2. Preparation of sample B: take 100g of H-MOR (sample A), use 1 molar concentration of oxalic acid s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com