Sensitive material for benzene vapor detecting sensor and preparation method of gas sensor

A technology for detecting sensors and gas-sensitive elements, which is applied in the direction of analyzing materials, material analysis by electromagnetic means, instruments, etc., can solve the problems of high material cost, complex equipment, and high maintenance cost, and achieves improved sensitivity and selectivity. Effect of temperature and power consumption, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The preparation method of benzene vapor detection sensor sensitive material and gas sensor in this example comprises the following steps:

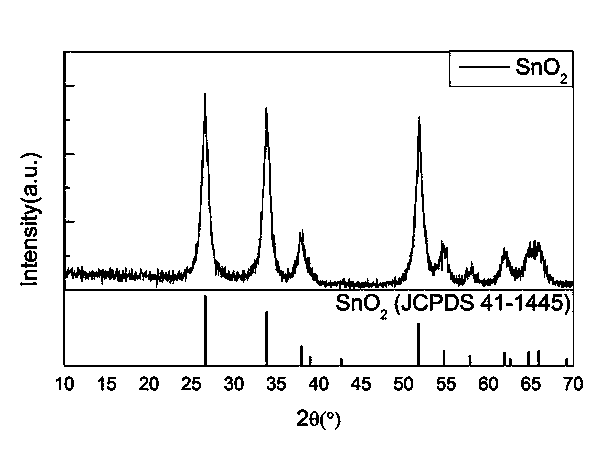

[0022] a.SnO 2 Preparation of nanomaterials: with SnCl 4 ·5H 2 O as a raw material, dissolved in deionized water to make a 0.05mol / L solution, stirred magnetically in a constant temperature water bath at 40°C for 30 minutes, added ammonia water dropwise to adjust the pH to 2-5; centrifuged to obtain a white colloidal precipitate, and then used to Ionized water and absolute ethanol were centrifuged and washed several times, dried to obtain gel particles, annealed at 500 ° C for 2 hours, and finely ground with an agate mortar to obtain SnO 2 nanomaterials;

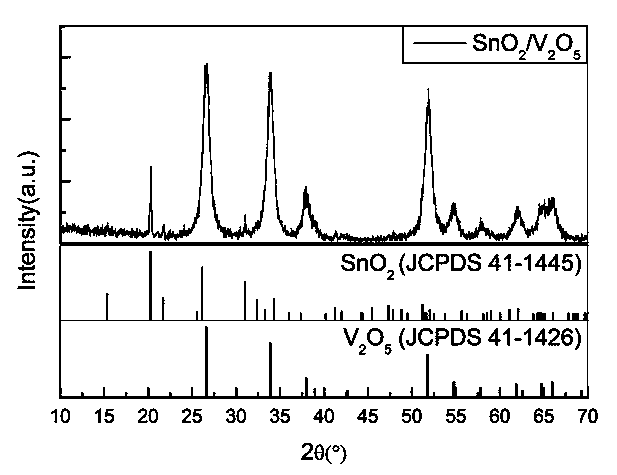

[0023] b.SnO 2 / V 2 o 5 Preparation of nanocomposites: the SnO 2 :V 2 o 5 According to the mass ratio of 99:1, the two nanomaterials are mixed and ground evenly, and the solid-state reaction is carried out at 600 ° C for 2 hours to obtain SnO 2 / V 2 o 5 Nanocomposite ...

Embodiment 2

[0026] The preparation method of benzene vapor detection sensor sensitive material and gas sensor in this example comprises the following steps:

[0027] a.SnO 2 Preparation of nanomaterials: with SnCl 4 ·5H 2 O as the raw material, dissolved in deionized water to make a 0.1 mol / L solution, stirred magnetically in a constant temperature water bath at 40°C for 40 minutes, added ammonia water dropwise to adjust the pH to 2-5; centrifuged to obtain a white colloidal precipitate, and then used Ionized water and absolute ethanol were centrifuged and washed several times, dried to obtain gel particles, annealed at 500 ° C for 2 hours, and finely ground with an agate mortar to obtain SnO 2 nanomaterials;

[0028] b.SnO 2 / V 2 o 5 Preparation of nanocomposites: the SnO 2 :V 2 o 5 According to the mass ratio of 9:1, the two nanomaterials are mixed and ground evenly, and the solid-state reaction is carried out at 600 ° C for 3 hours to obtain SnO 2 / V 2 o 5 Nanocomposite ma...

Embodiment 3

[0031] The preparation method of benzene vapor detection sensor sensitive material and gas sensor in this example comprises the following steps:

[0032] a.SnO 2 Preparation of nanomaterials: with SnCl 4 ·5H 2 O as the raw material was dissolved in deionized water to make a 0.2 mol / L solution, magnetically stirred in a constant temperature water bath at 40°C for 50 minutes, and ammonia water was added dropwise to adjust the pH to 2-5; a white colloidal precipitate was obtained after centrifugation, and then used to Ionized water and absolute ethanol were centrifuged and washed several times, dried to obtain gel particles, annealed at 500 ° C for 2 hours, and finely ground with an agate mortar to obtain SnO 2 nanomaterials;

[0033] b.SnO 2 / V 2 o 5 Preparation of nanocomposites: the SnO 2 :V 2 o 5 According to the mass ratio of 4:1, the two nanomaterials are mixed and ground evenly, and the solid-state reaction is carried out at 600 ° C for 3 hours to obtain SnO 2 / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com