Method for reclamation and cyclic utilization of tail gas containing benzene and hydrogenchloride in chlorobenzene production

A technology of hydrogen chloride gas and chlorinated benzene, which is applied in chemical instruments and methods, separation methods, disproportionation separation/purification of halogenated hydrocarbons, etc., can solve the problems of unseen recovery and utilization of benzene and hydrogen chloride, waste of resources, environment, retention, etc., to achieve High recovery rate, environmental protection, and the effect of reducing benzene consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Now further illustrate how the present invention is implemented in conjunction with examples.

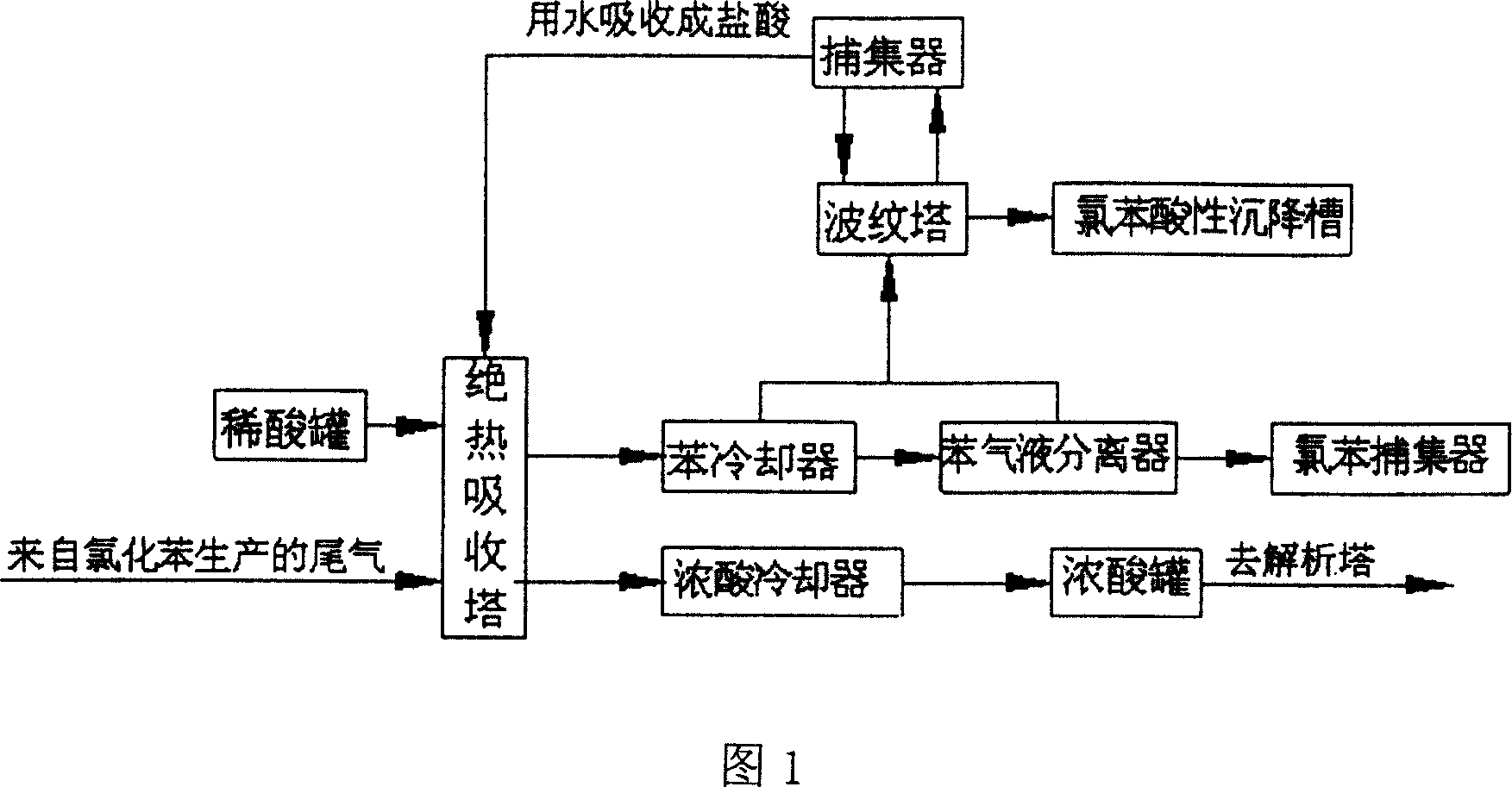

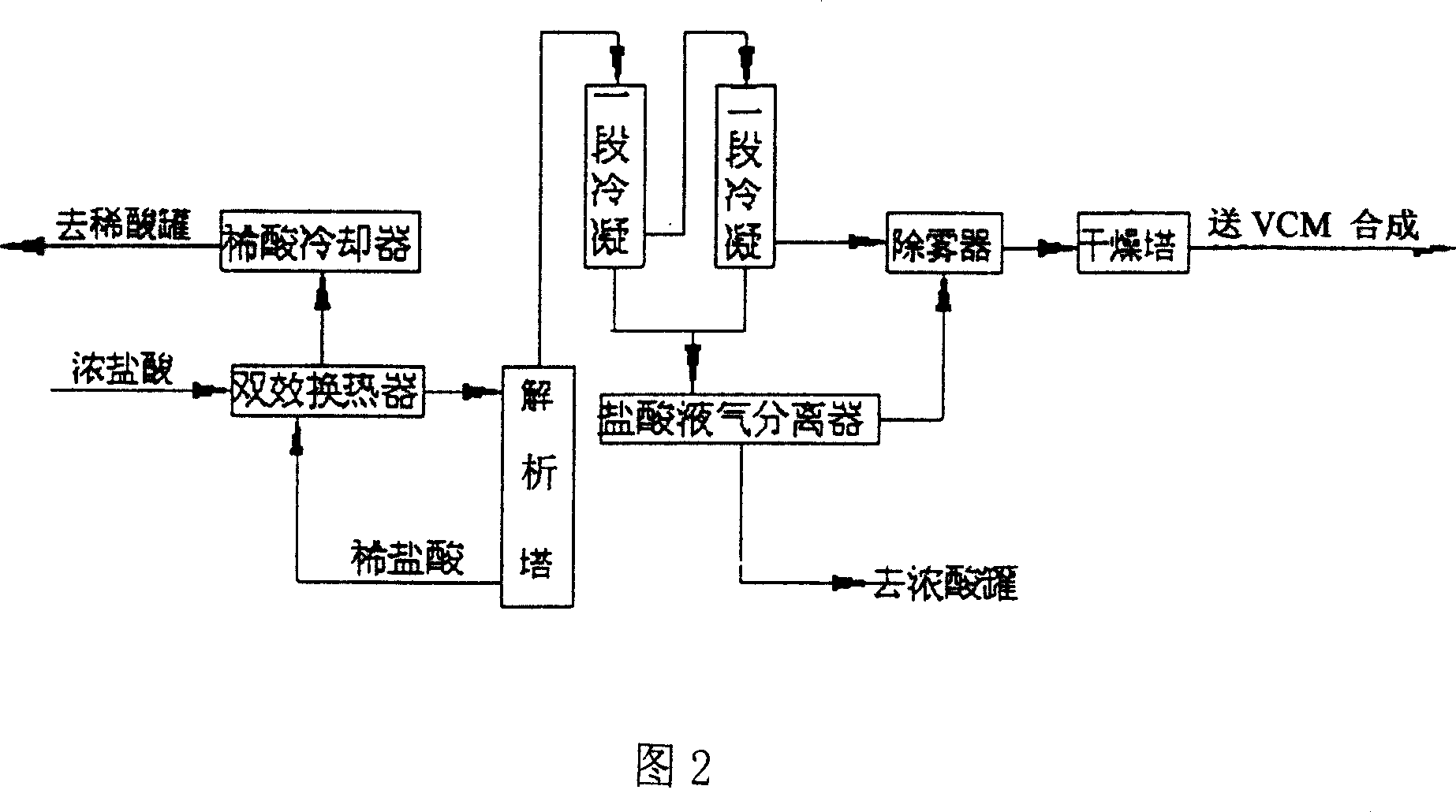

[0014] The hydrogen chloride tail gas produced from chlorinated benzene enters the adiabatic absorption tower in batches through the tail gas distribution platform. The tail gas entering the adiabatic tower is about 1016kg at a time. The top temperature is 81°C, and the amount of dilute hydrochloric acid added is about 2000kg. After the counter-flow mass transfer of dilute hydrochloric acid and hydrogen chloride, the benzene vapor in the tail gas enters the top of the adiabatic tower; Concentrated hydrochloric acid, at this moment, the concentrated hydrochloric acid of 31.2% is about 2950kg sent from the bottom of the adiabatic absorption tower. A small amount of hydrogen chloride, about 66kg, is condensed in the benzene condenser, and then separated by the gas-liquid separator. About 15kg of gaseous benzene is sent to the chlorinated benzene production system for recycling. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com