Method for preparing ethylbenzene by ethanol and benzene vapor-phase alkylation

A technology of alkylation and ethanol, applied in chemical instruments and methods, organic chemistry, molecular sieve catalysts, etc., can solve the problems of poor catalyst stability, short regeneration cycle, high content of xylene impurities, etc., and achieve good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

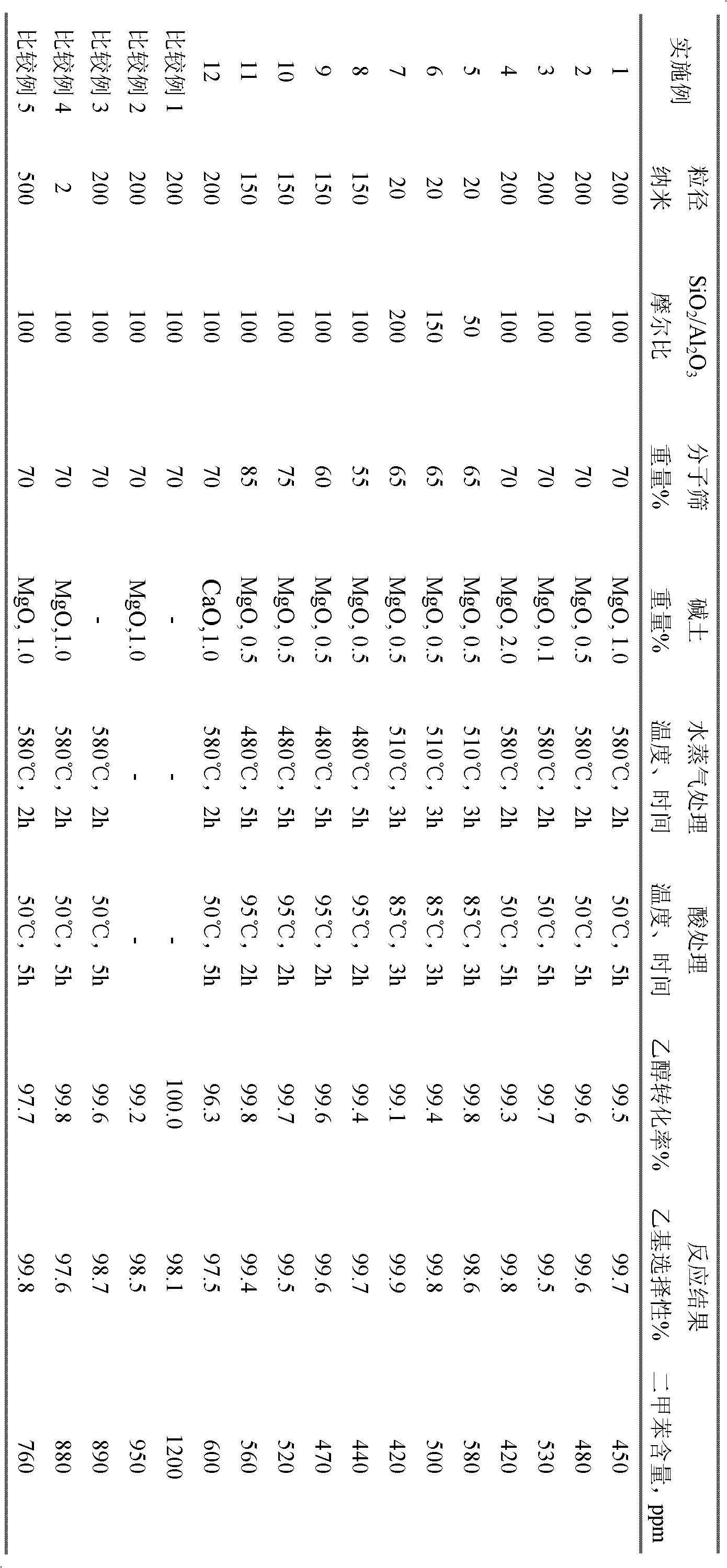

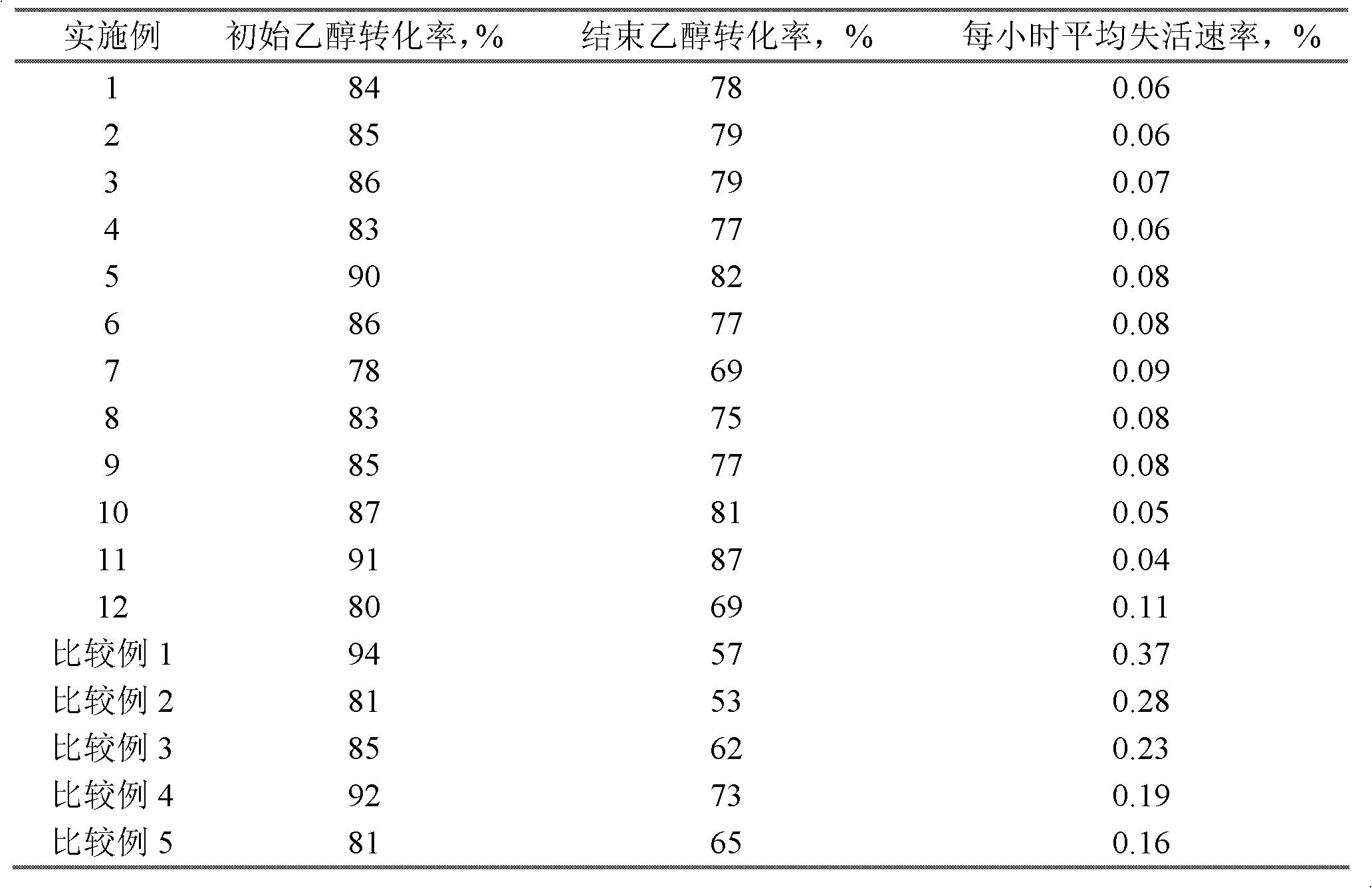

[0023] 200g SiAl Molar Ratio SiO 2 / Al 2 o 3 =100, the ZSM-5 molecular sieve with a grain diameter of 200 nanometers is exchanged three times with 2 liters of 0.1 mol / liter hydrochloric acid at 85°C, washed with deionized water until there is no chlorine radical, dried at 110°C, and then calcined at 580°C for 4 hours Backup.

[0024] 20 grams of the above-mentioned molecular sieves and 50 milliliters of 0.25 mol / liter magnesium nitrate aqueous solution were impregnated at room temperature for 4 hours, then dried at 110° C., and then calcined at 550° C. for 4 hours. Mix it with alumina binder at a ratio of 70:30, add 2% of scallop powder and 10% by weight of dilute nitric acid solution, knead, and extrude to form a Φ1.8mm strip. After baking at 110°C for 10 hours, and then baking at 550°C for 4 hours, the obtained catalyst contains 1.0% by weight of MgO.

[0025] Treat the above catalyst with water vapor at 580°C under normal pressure for 2 hours, and then treat it with 1.5...

Embodiment 2~11

[0027] Same as [Example 1], just change the SiO of ZSM-5 molecular sieve 2 / Al 2 o 3 Molar ratio, grain size, ratio of molecular sieve to alumina and alkaline earth metal oxide, steam treatment and phosphoric acid treatment conditions. See Table 1 for details.

Embodiment 12

[0039] Same as [Example 1], except that the catalyst contains 1.0% by weight of CaO.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com