Continuous flow method for measuring total alkaloid in tobacco or tobacco products

A technology for tobacco products and plant alkaloids, which is applied in the preparation of test samples, measurement of color/spectral characteristics, and material analysis by observing the impact on chemical indicators, etc. It can solve the problems of inconvenient use and large amount of chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

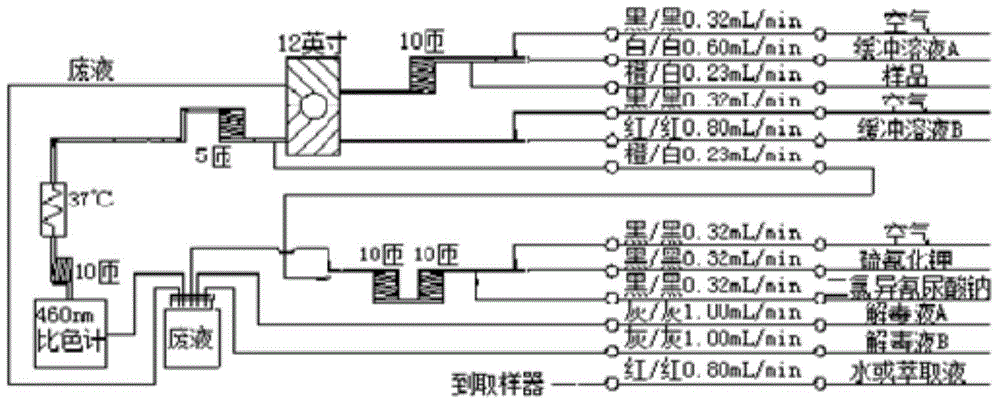

Method used

Image

Examples

Embodiment 1

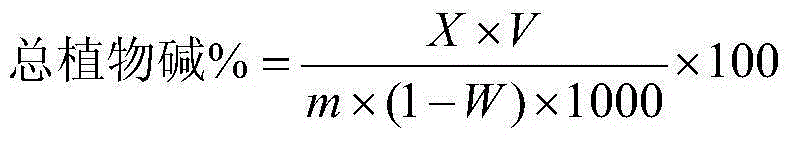

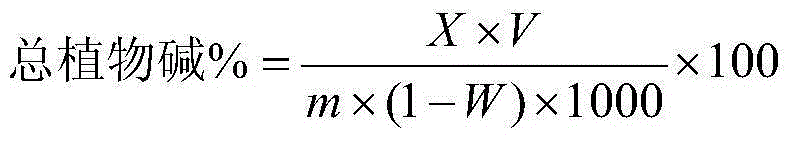

[0079] Example 1 : Determination of total plant alkaloids in flue-cured tobacco

[0080] 1) Sample pretreatment

[0081] Prepare the flue-cured tobacco powder into a sample according to YC / T31, and measure its moisture content, then weigh 0.25g of the sample in a 50mL Erlenmeyer flask with a stopper, add 25mL of 5% acetic acid, cover the stopper, and vibrate on a shaker (rotating speed >150rpm) extraction for 30min. Filter the extract with rapid qualitative filter paper, discard the first 2mL-3mL filtrate, and collect the subsequent filtrate for analysis.

[0082] 2) Preparation of reaction reagents

[0083] The preparation of buffer solution A is as follows: Weigh 71.6 grams of disodium hydrogen phosphate (12 crystal waters) and 15.2 grams of trisodium phosphate (12 crystal waters) into a beaker, dissolve them in water, then transfer them to a 1L volumetric flask, and dilute with water. To the scale.

[0084] The preparation of buffer solution B is: weigh 7g p-aminobenz...

Embodiment 2

[0109] Embodiment 2: the mensuration of total plant alkaloids in Burley tobacco

[0110] 1) Sample pretreatment

[0111] Prepare a sample of Burley tobacco powder according to YC / T31, and measure its moisture content, then weigh 0.25g of Burley tobacco sample in a 50mL conical flask with a stopper, add 25mL of 5% acetic acid, cover the stopper, and shake Shake on the device (rotational speed > 150rpm) and extract for 30min. Filter the extract with rapid qualitative filter paper, discard the first 2mL-3mL filtrate, and collect the subsequent filtrate for analysis.

[0112] 2) Preparation of reaction reagents

[0113] The preparation of buffer solution A is as follows: Weigh 71.6 grams of disodium hydrogen phosphate (12 crystal waters) and 15.2 grams of trisodium phosphate (12 crystal waters) into a beaker, dissolve them in water, then transfer them to a 1L volumetric flask, and dilute with water. To the scale.

[0114] The preparation of buffer solution B is: weigh 7g p-ami...

Embodiment 3

[0138] Embodiment 3: Determination of total plant alkaloids in cigarette

[0139] 1) Sample pretreatment

[0140] Prepare cigarette shredded tobacco as a sample according to YC / T31, and measure its moisture content, then weigh 0.25g of the cigarette sample into a 50mL Erlenmeyer flask with a stopper, add 25mL of 5% acetic acid, cover the stopper, and oscillate on a shaker (speed >150rpm) extraction for 30min. Filter the extract with rapid qualitative filter paper, discard the first 2mL-3mL filtrate, and collect the subsequent filtrate for analysis.

[0141] 2) Preparation of reaction reagents

[0142] The preparation of buffer solution A is as follows: Weigh 83.0 grams of disodium hydrogen phosphate (12 crystal waters) and 20.0 grams of trisodium phosphate (12 crystal waters) into a beaker, dissolve them in water, then transfer them to a 1L volumetric flask, and dilute with water. To the scale.

[0143] The preparation of buffer solution B is: weigh 7g of p-aminobenzenesul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com