Esterification process of cyanate ester resin

A cyanate ester resin and esterification technology, which is applied in the direction of control/adjustment process, chemical instruments and methods, chemical/physical process, etc., can solve the problems of unfavorable reaction uniformity and heat exchange, fixed stirring frequency, and increased viscosity of materials, etc. , to avoid large fluctuations in temperature control and improve heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A cyanate ester resin esterification process includes the following steps:

[0039] Step S1: Weigh the following raw materials by weight: 10 parts of diphenol propane, 0.5 parts of triethylamine, 35 parts of acetone, 25 parts of absolute ethanol, 20 parts of cyanogen chloride;

[0040] Step S2. Diphenol propane and triethylamine are added to a beaker containing acetone, heated in a water bath at 45°C, stirred at a rotation speed of 100r / min for 45 minutes, and allowed to stand for 30 minutes to prepare a mixture A;

[0041] Step S3, the reaction is carried out through the reactor, and the specific steps are as follows:

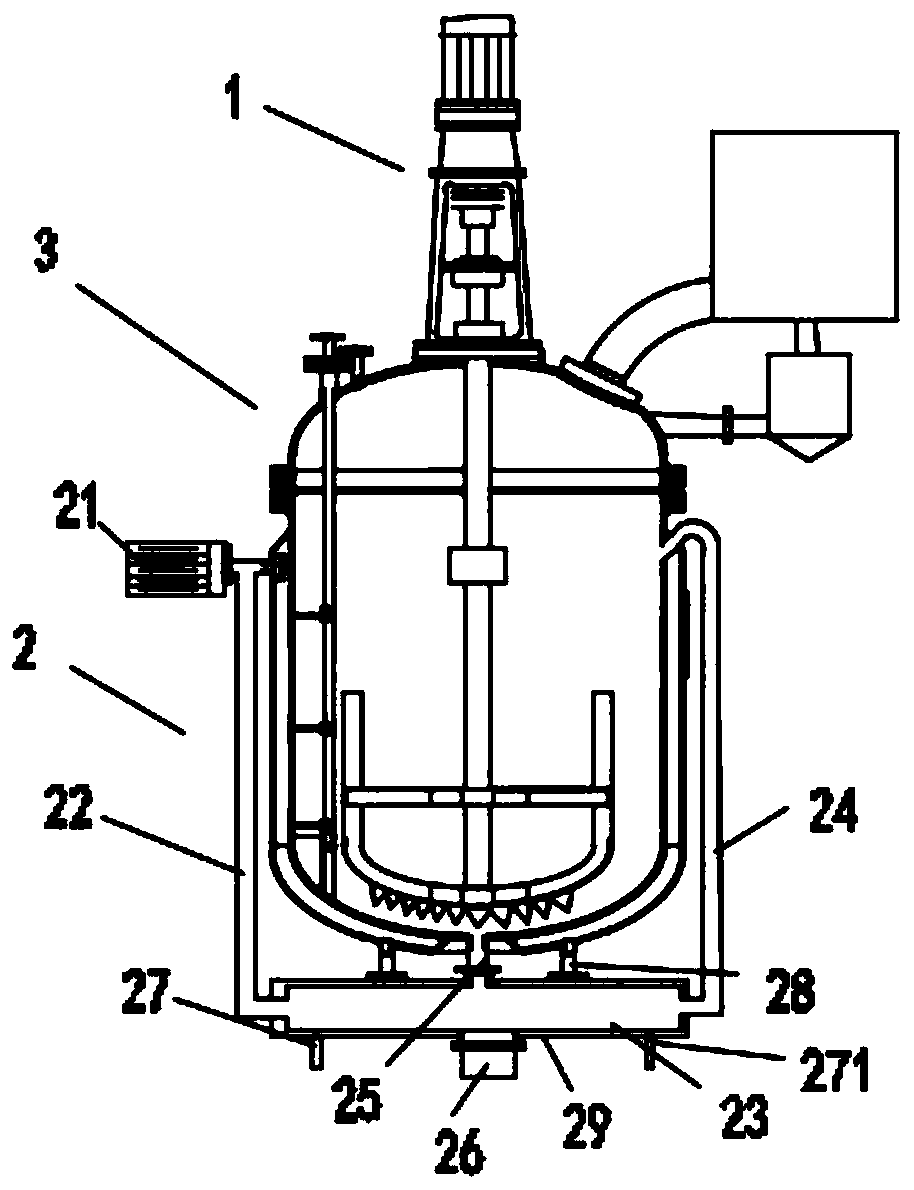

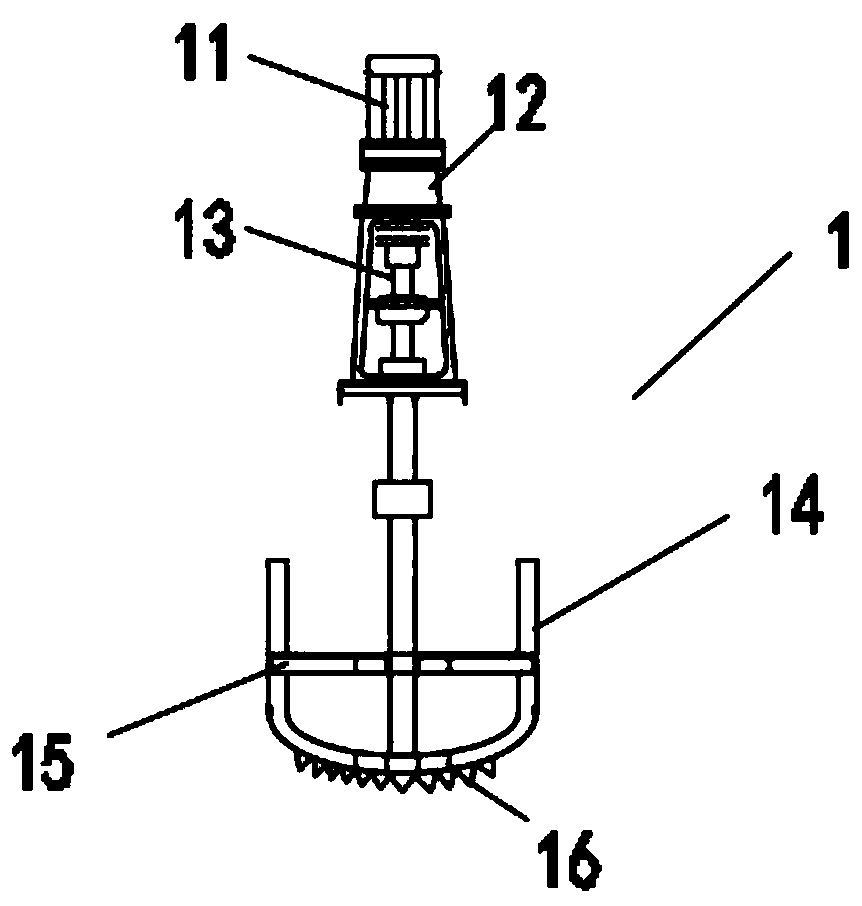

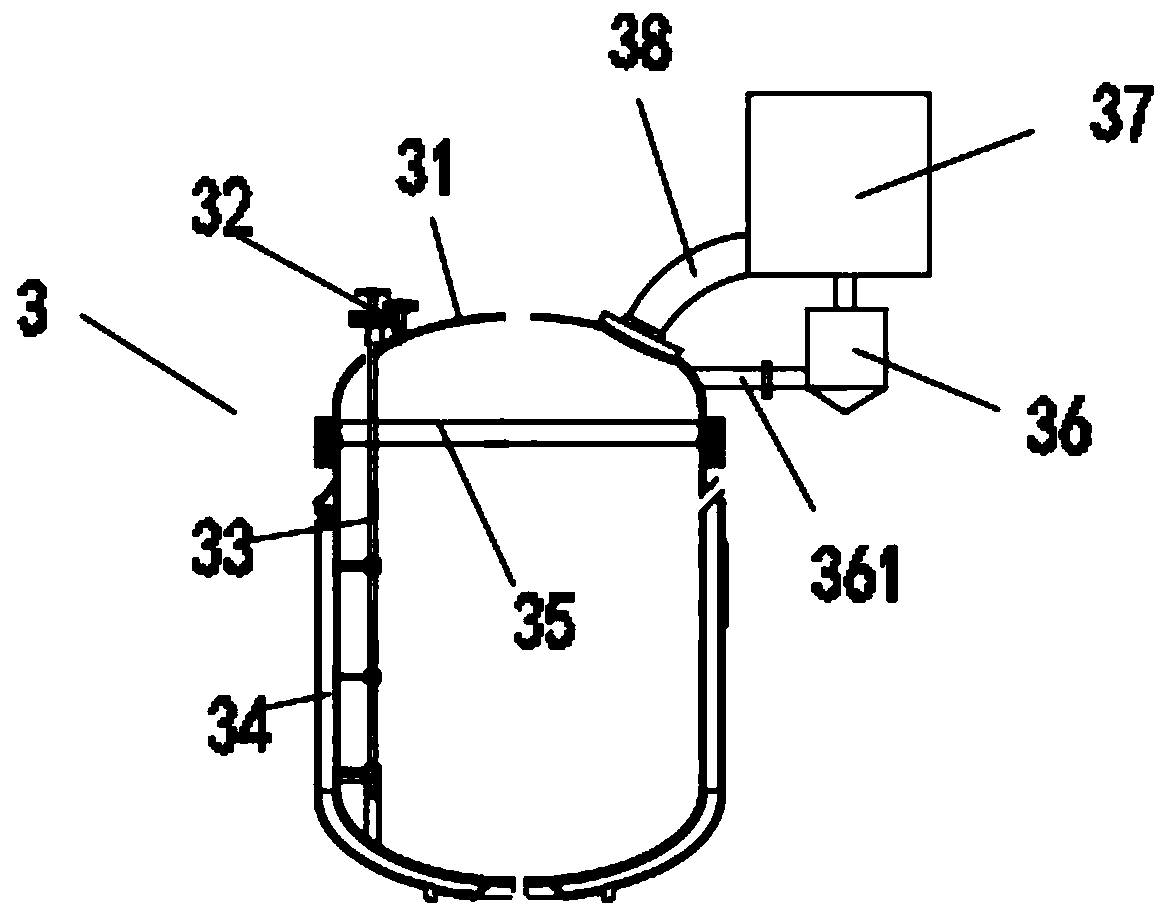

[0042] The first step is to add anhydrous ethanol and cyanogen chloride into the second storage tank of the reactor to form materials. The feed controller controls half of the materials to enter the kettle body, turn on the stirring motor, and the stirring motor drives the transmission rod to rotate, driving the U-shape The stirrer rotates to control the temper...

Embodiment 2

[0046] A cyanate ester resin esterification process includes the following steps:

[0047] Step S1: Weigh the following raw materials by weight: 12 parts of diphenol propane, 0.6 parts of triethylamine, 40 parts of acetone, 28 parts of absolute ethanol, 22 parts of cyanogen chloride;

[0048] Step S2. Diphenol propane and triethylamine are added to a beaker containing acetone, heated in a water bath at 45°C, stirred at a rotation speed of 100r / min for 45 minutes, and allowed to stand for 30 minutes to prepare a mixture A;

[0049] Step S3, the reaction is carried out through the reactor, and the specific steps are as follows:

[0050] The first step is to add anhydrous ethanol and cyanogen chloride into the second storage tank of the reactor to form materials. The feed controller controls half of the materials to enter the kettle body, turn on the stirring motor, and the stirring motor drives the transmission rod to rotate, driving the U-shape The stirrer rotates to control the temper...

Embodiment 3

[0054] A cyanate ester resin esterification process includes the following steps:

[0055] Step S1: Weigh the following raw materials by weight: 13 parts of diphenol propane, 0.8 parts of triethylamine, 45 parts of acetone, 32 parts of absolute ethanol, 28 parts of cyanogen chloride;

[0056] Step S2. Diphenol propane and triethylamine are added to a beaker containing acetone, heated in a water bath at 45°C, stirred at a rotation speed of 100r / min for 45 minutes, and allowed to stand for 30 minutes to prepare a mixture A;

[0057] Step S3, the reaction is carried out through the reactor, and the specific steps are as follows:

[0058] The first step is to add anhydrous ethanol and cyanogen chloride into the second storage tank of the reactor to form materials. The feed controller controls half of the materials to enter the kettle body, turn on the stirring motor, and the stirring motor drives the transmission rod to rotate, driving the U-shape The stirrer rotates to control the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com