Flour machine with drying function

A drying function, flour mill technology, applied in grain processing and other directions, can solve the problems of flour without good preservation equipment, poor quality, and difficult to preserve, and achieve the effect of ensuring quality problems, improving quality, and increasing feeding speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

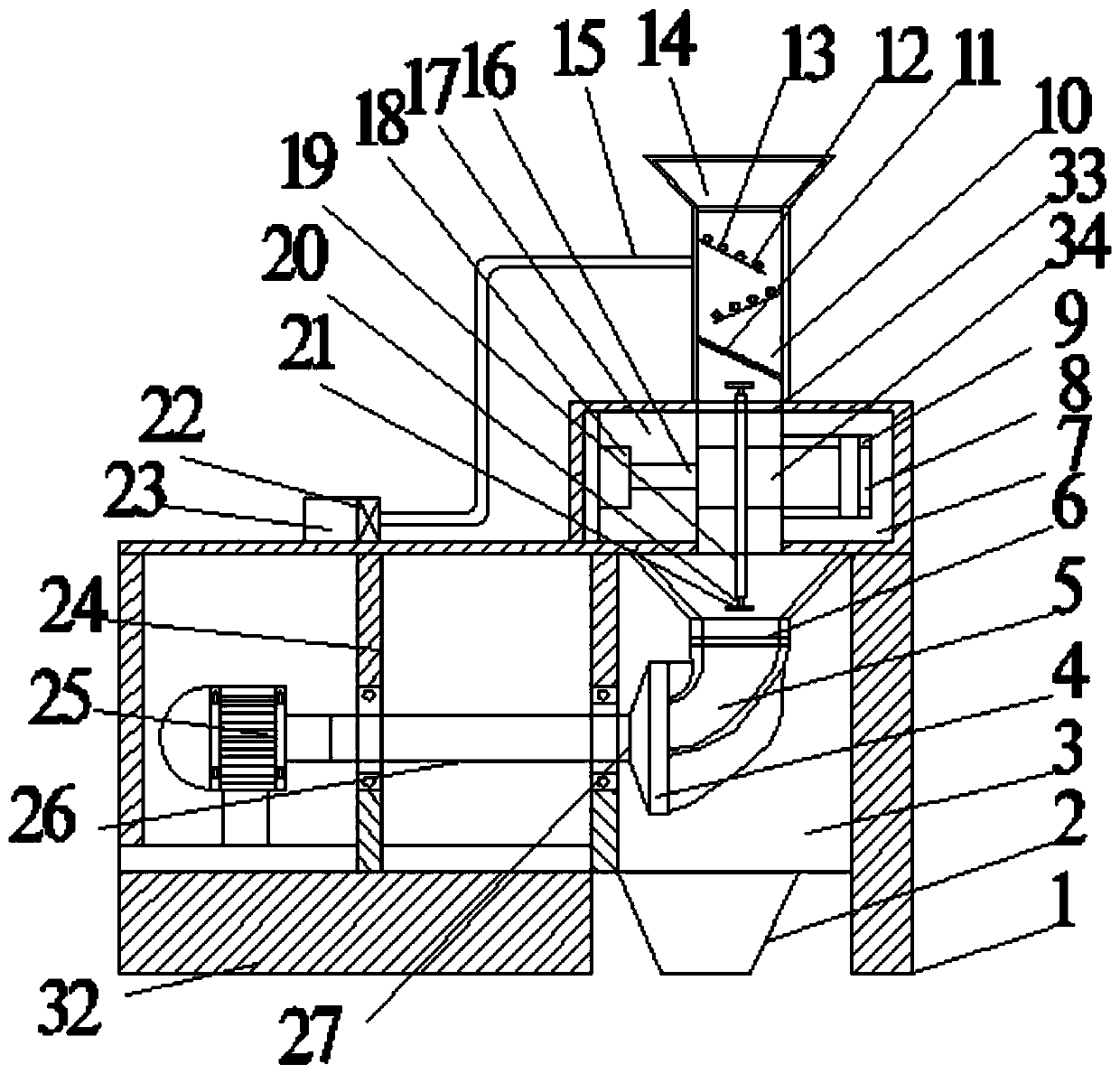

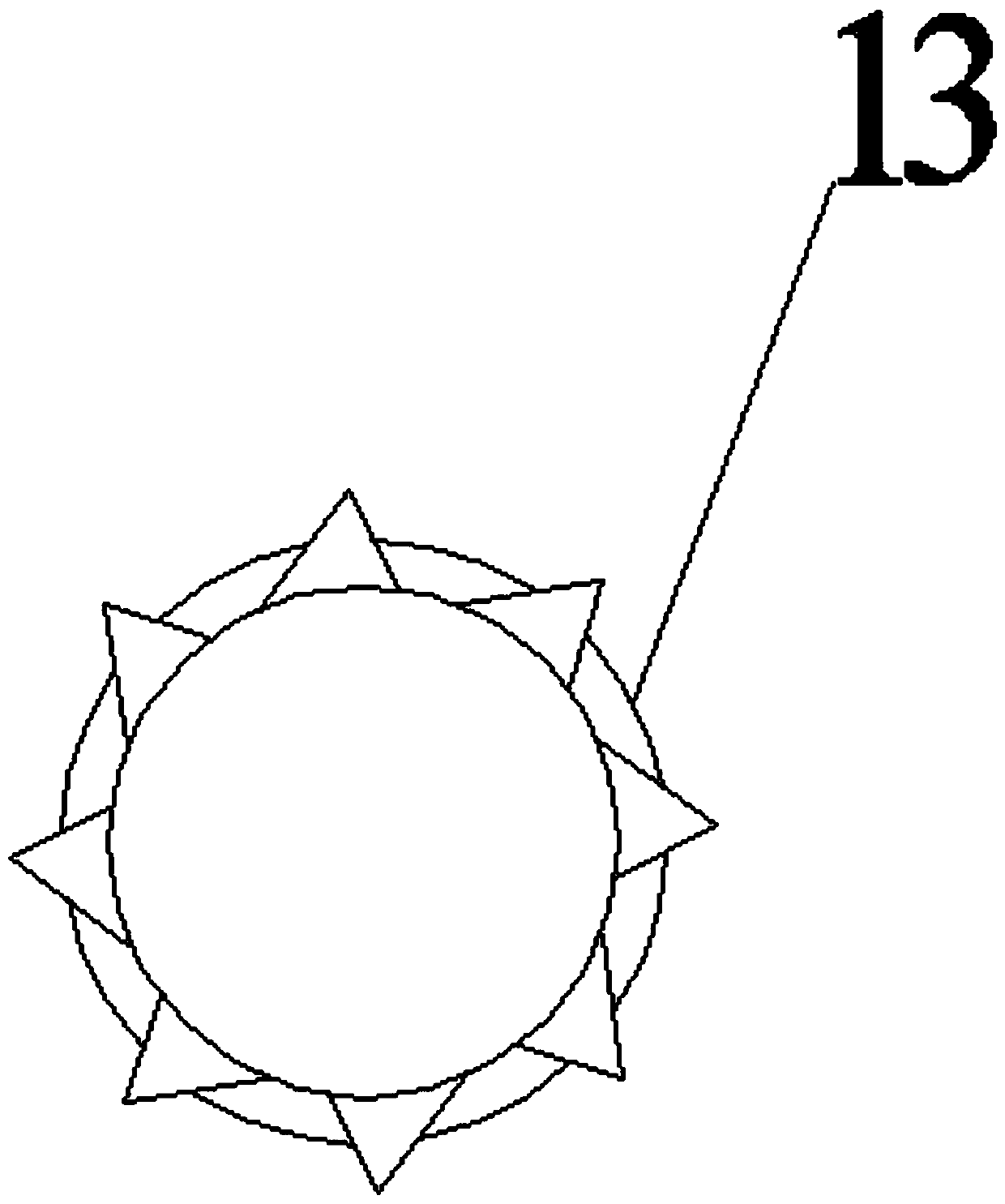

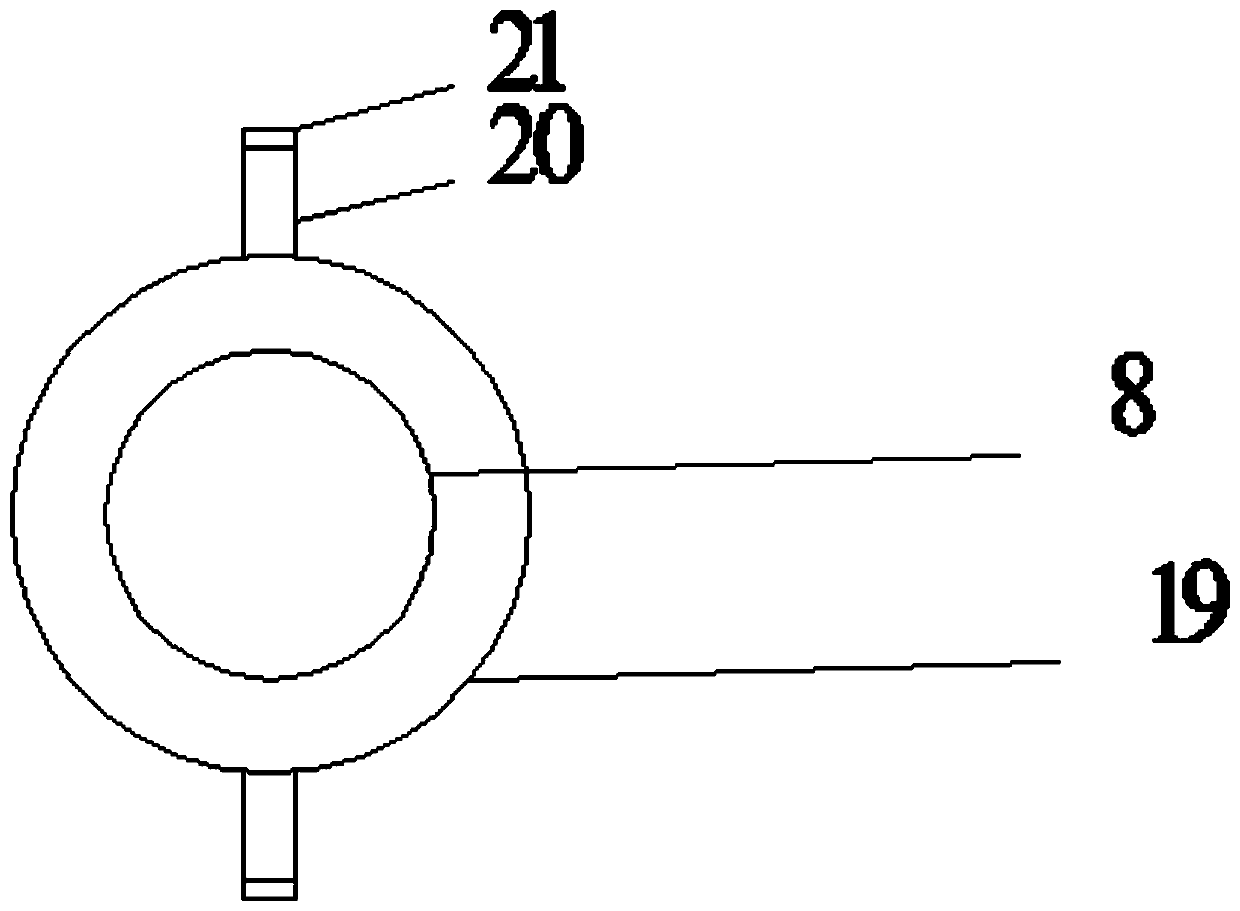

[0024] see Figure 1-3 , a flour machine with a drying function, comprising a base 32 and a flour milling chamber 3, the top of the base 32 is provided with a first motor 25, the output shaft of the first motor 25 passes through the supporting column 24 and is connected to one end of the rotating shaft 26 for rotation , the other end of the rotating shaft 26 is fixedly connected with a shaft coupling 27, and the shaft coupling 27 is fixedly connected with the noodle grinder 4. By starting the first motor 25, the operation of the noodle grinder 4 is driven. The flour mill 4 is arranged on one side of the flour milling chamber 3 , and the other side of the flour milling chamber 3 is provided with a support 1 . One side of the noodle grinder 4 is connected with a noodle delivery pipeline 5, and the top of the noodle delivery pipeline 5 is connected with a one-way valve 6, and the one-way valve 6 prevents the backflow of flour. A noodle storage tank 2 is arranged below the noodl...

Embodiment 2

[0028] refer to Figure 4 , on the basis of Embodiment 1, the bottom of the surface storage tank 2 is provided with a heating base 28, and the inside of the heating base 28 is provided with a pipe row 29, and one side of the heating base 28 is communicated with an air supply pipeline 30, and the air supply pipeline 30 is connected to To the air outlet pipe of heating fan 31. By sending the hot air in the heating fan 31 into the row pipe 29, then the bottom of the noodle storage tank 2 is heated by the row pipe 29, thereby preventing the bottom of the noodle storage tank 2 from damaging the quality of the flour due to moisture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com