A kind of cyanate ester resin esterification process

A cyanate resin, esterification technology, applied in control/adjustment process, chemical instrument and method, chemical/physical process, etc., can solve the problems of uniform reaction and heat exchange, fixed stirring frequency, low heat exchange efficiency, etc. , to avoid large fluctuations in temperature control and improve heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of cyanate ester resin esterification process, comprises the steps:

[0039] Step S1, weighing the following raw materials in parts by weight: 10 parts of diphenolic propane, 0.5 parts of triethylamine, 35 parts of acetone, 25 parts of absolute ethanol, and 20 parts of cyanogen chloride;

[0040] Step S2, adding diphenolic propane and triethylamine into a beaker filled with acetone, heating in a water bath at 45°C, stirring at a speed of 100r / min for 45min, and standing for 30min to prepare a mixed solution A;

[0041] Step S3, reacting through the reactor, the specific steps are as follows:

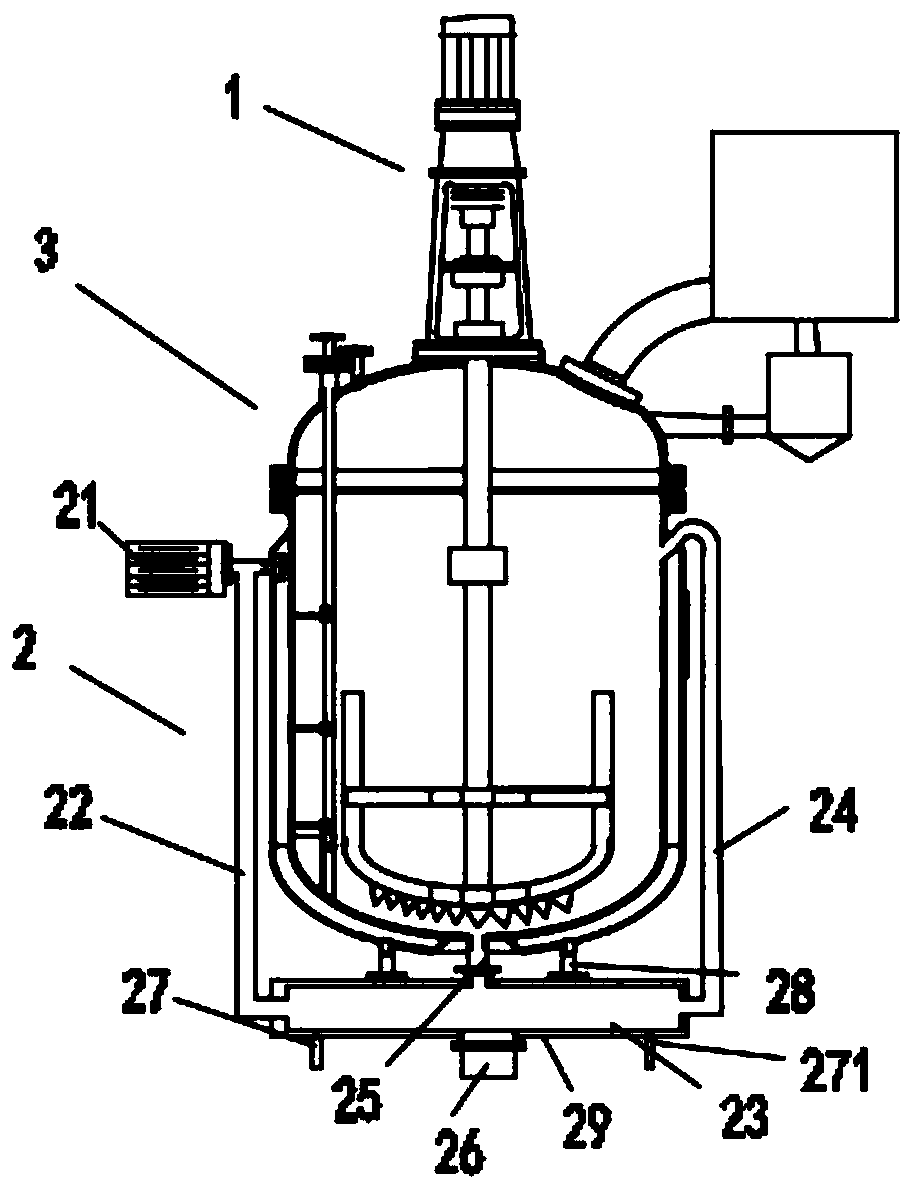

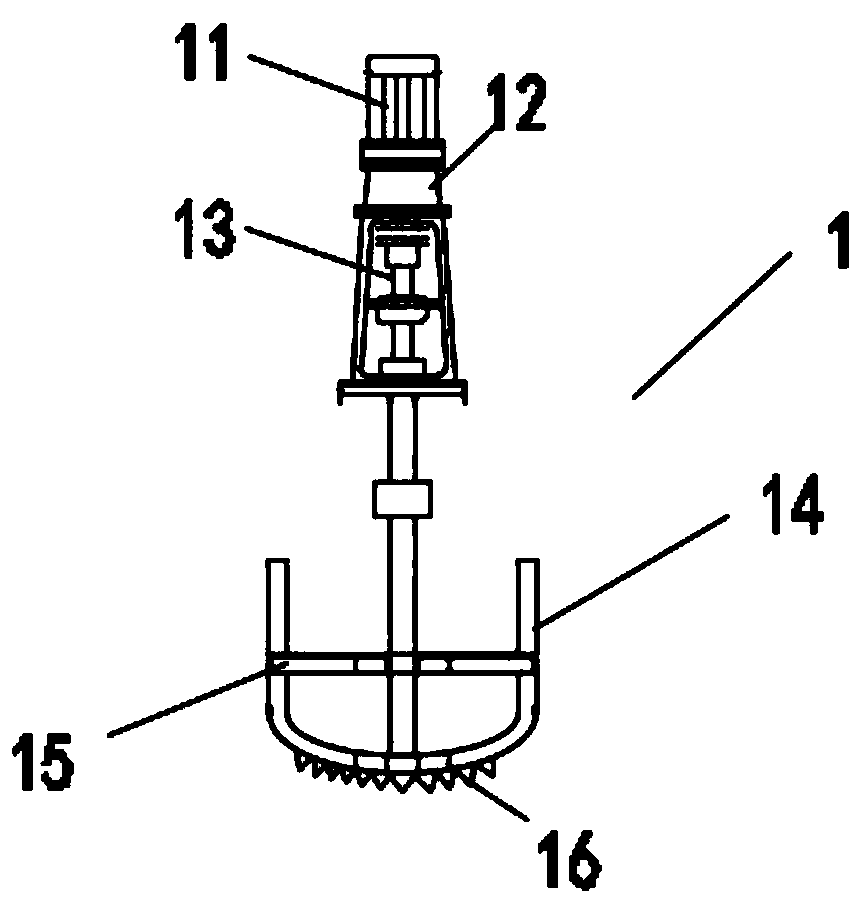

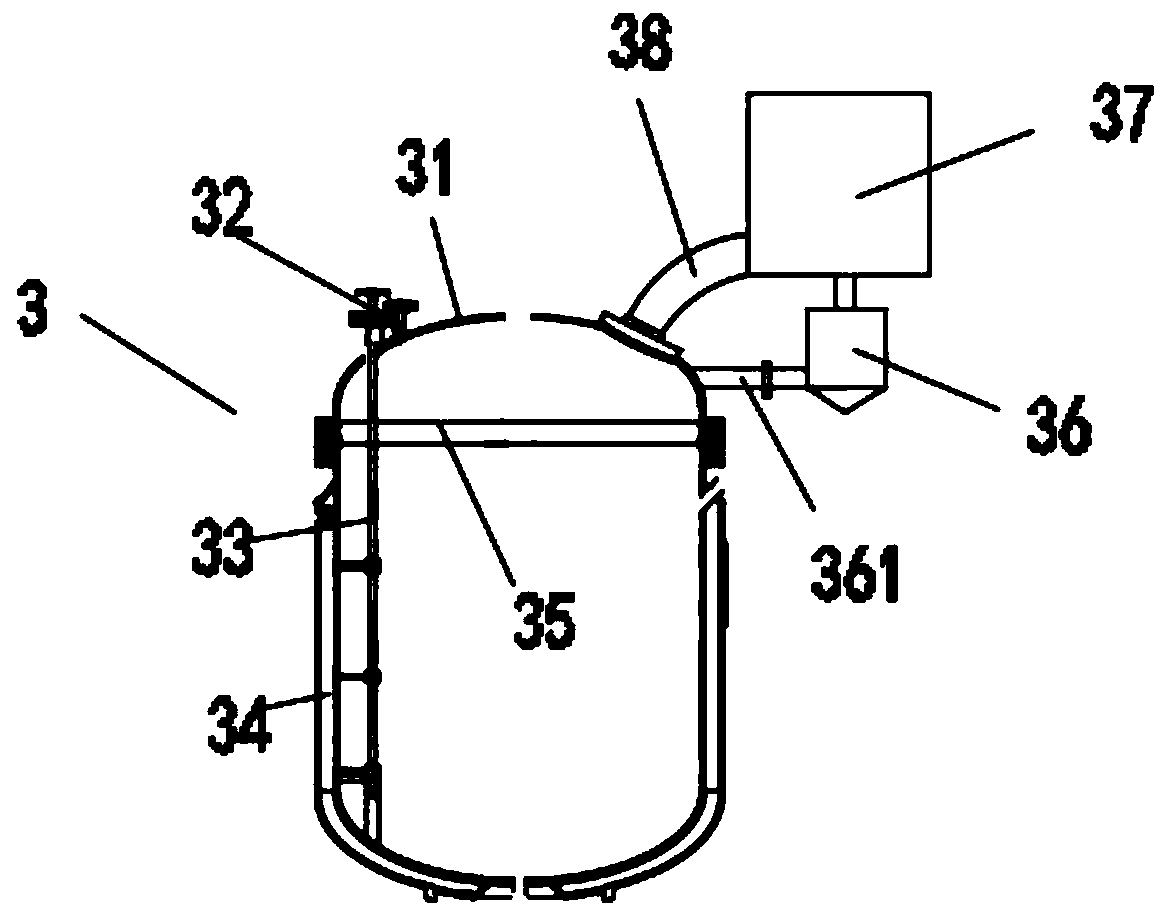

[0042] The first step is to add absolute ethanol and cyanogen chloride to the second storage box of the reaction kettle to form materials. The feed controller controls half of the materials to enter the interior of the kettle body, and turns on the stirring motor. The stirring motor drives the transmission rod to rotate and drives the U-shaped The stirrer is rotated, and t...

Embodiment 2

[0046] A kind of cyanate ester resin esterification process, comprises the steps:

[0047] Step S1, weighing the following raw materials in parts by weight: 12 parts of diphenolic propane, 0.6 parts of triethylamine, 40 parts of acetone, 28 parts of absolute ethanol, and 22 parts of cyanogen chloride;

[0048] Step S2, adding diphenolic propane and triethylamine into a beaker filled with acetone, heating in a water bath at 45°C, stirring at a speed of 100r / min for 45min, and standing for 30min to prepare a mixed solution A;

[0049] Step S3, reacting through the reactor, the specific steps are as follows:

[0050] The first step is to add absolute ethanol and cyanogen chloride to the second storage box of the reaction kettle to form materials. The feed controller controls half of the materials to enter the interior of the kettle body, and turns on the stirring motor. The stirring motor drives the transmission rod to rotate and drives the U-shaped The stirrer is rotated, and t...

Embodiment 3

[0054] A kind of cyanate ester resin esterification process, comprises the steps:

[0055] Step S1, weighing the following raw materials in parts by weight: 13 parts of diphenolic propane, 0.8 parts of triethylamine, 45 parts of acetone, 32 parts of absolute ethanol, and 28 parts of cyanogen chloride;

[0056] Step S2, adding diphenolic propane and triethylamine into a beaker filled with acetone, heating in a water bath at 45°C, stirring at a speed of 100r / min for 45min, and standing for 30min to prepare a mixed solution A;

[0057] Step S3, reacting through the reactor, the specific steps are as follows:

[0058] The first step is to add absolute ethanol and cyanogen chloride to the second storage box of the reaction kettle to form materials. The feed controller controls half of the materials to enter the interior of the kettle body, and turns on the stirring motor. The stirring motor drives the transmission rod to rotate and drives the U-shaped The stirrer is rotated, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com