Method for purifying waste gases produced during the production of cyanuric chloride

A cyanuric chloride and tail gas technology, applied in chemical instruments and methods, cyanogen halide, separation methods, etc., can solve the problems of unstable chlorine content, easy change, low reaction rate of chlorine and hydrogen cyanide, etc., and achieve cost and production. The effect of low cost, efficient cleaning steps, and low technical complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

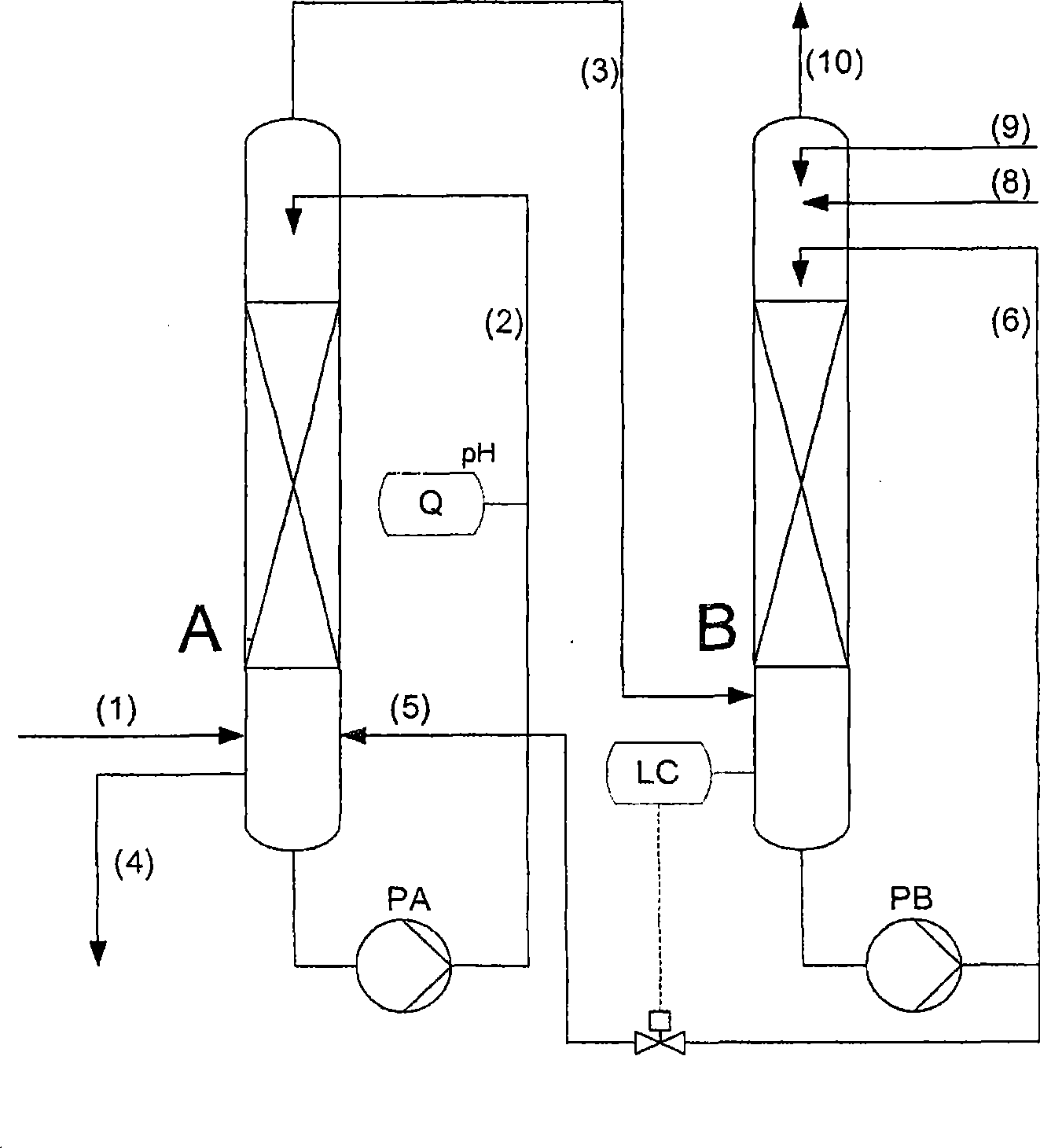

[0018] Column B is filled with water via line 9 to a level of about 1 m below line 3 . Then turn on the circulating pump PB (150m 3 / h), and the level is maintained at this level with the LIC. When the lower part of column A overflows in line 4, the circulating pump PA (150m 3 / h). Now, adjust the amount of water provided to 4m 3 / h, and add 30% sodium hydroxide solution until the pH in column A>10. The introduction of the tail gas obtained in the preparation of cyanuric chloride can now be started.

[0019] The obtained tail gas (about 12000m 3 / h) Introduced into the lower part of the washing column A, wherein the tail gas contains, in addition to air, about 200 kg of chlorine and about 25 kg of cyanogen chloride. The alkaline hypochlorite (hypochlorite forms immediately when chlorine gas is introduced into the sodium hydroxide solution) aqueous solution pumped in by line 2 circulation removes part of the chlorine gas and almost all of the cyanogen chloride in the tail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com