Cyanogen chloride preparation process for cyanate ester resin synthesis

A cyanate ester resin and preparation process technology, applied in cyanogen halide, cyanide, inorganic chemistry and other directions, can solve the problems of high cost, poor heat transfer performance, poor mixing effect, etc., to reduce equipment cost, reduce processing difficulty, The effect of increasing the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

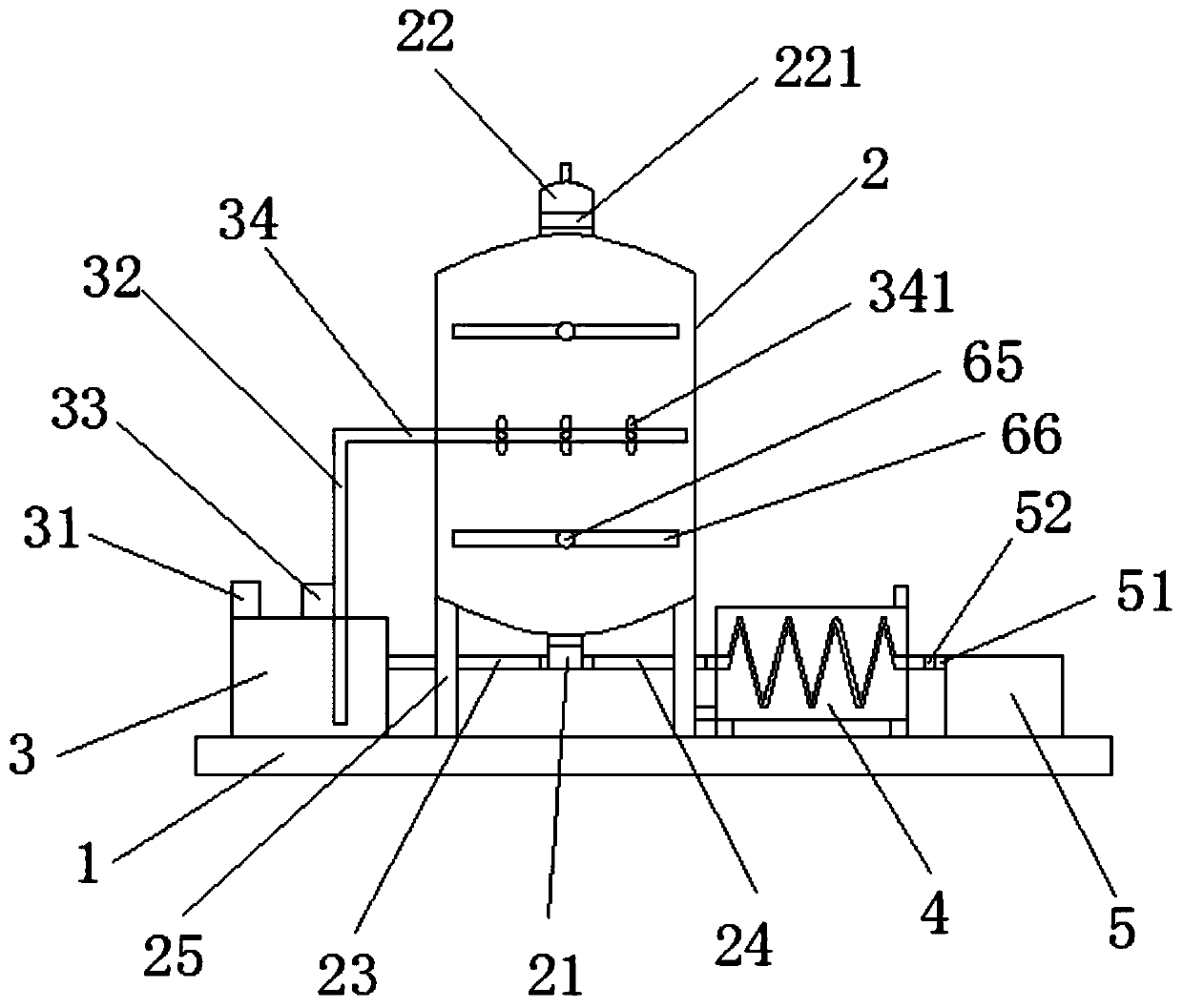

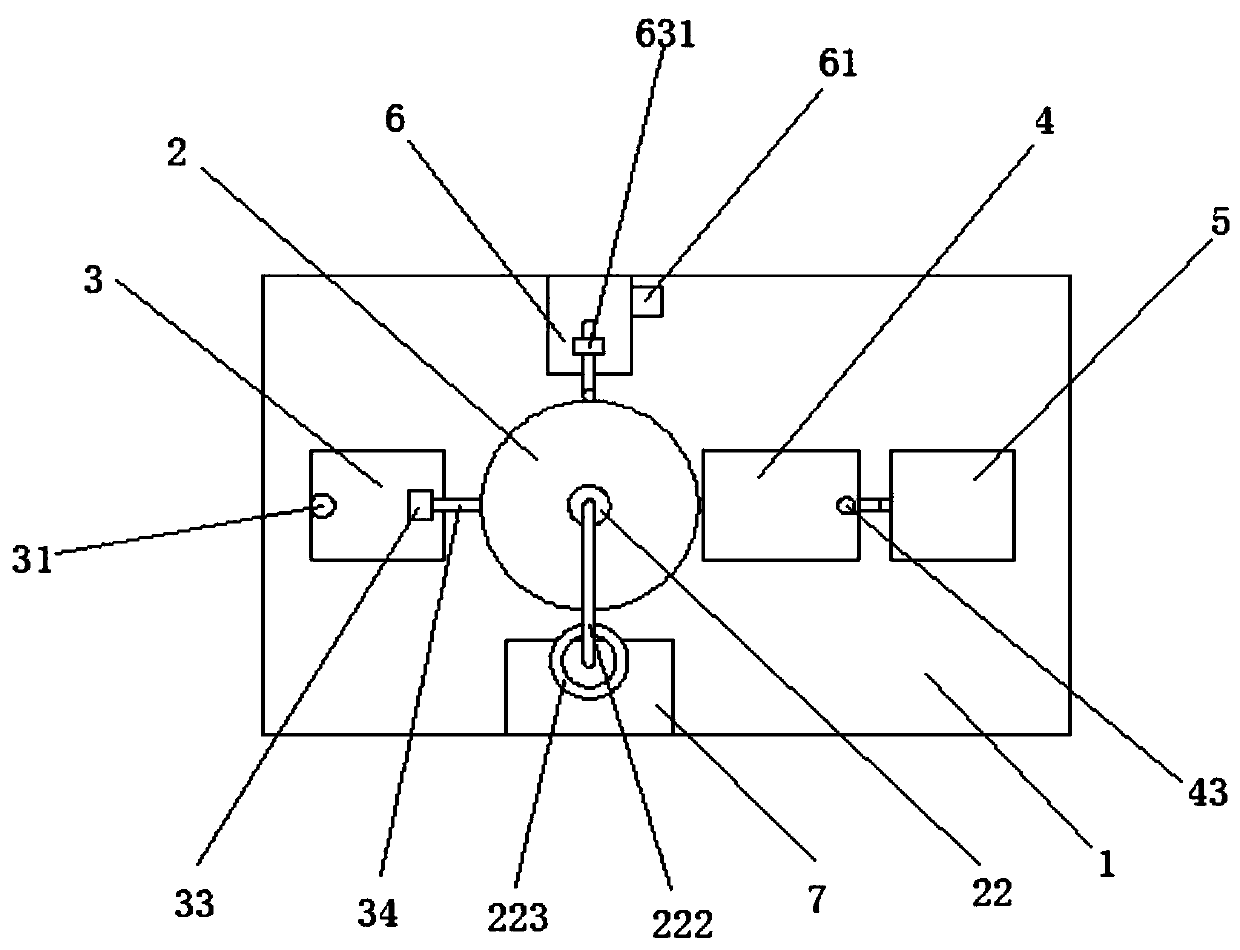

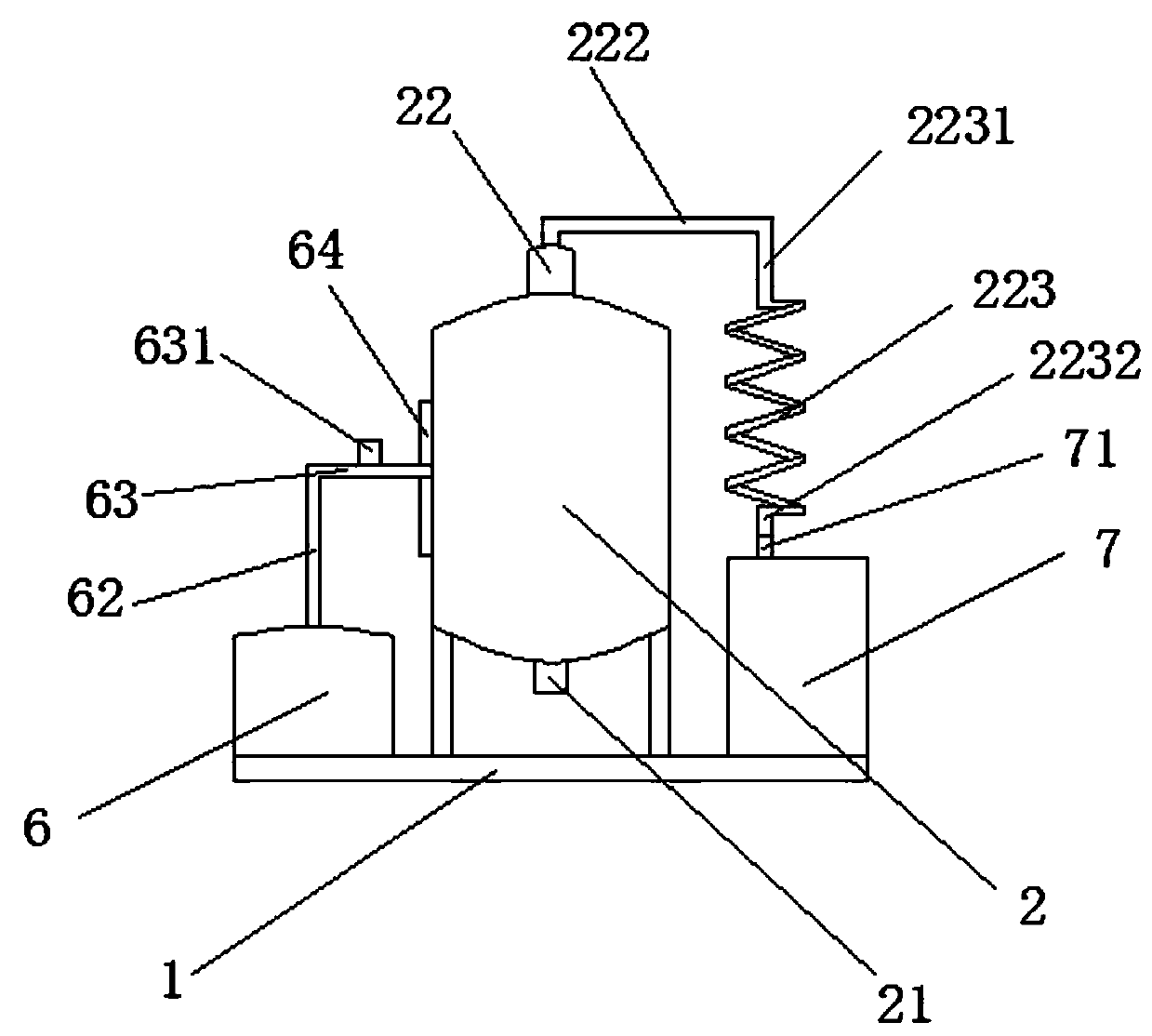

Image

Examples

Embodiment 1

[0034] A kind of cyanogen chloride preparation technology that is used for cyanate resin synthesis comprises the steps:

[0035] Step S1: Weigh the following raw materials in parts by weight: 10 parts of sodium cyanide solution and 7 parts of liquid chlorine;

[0036] Step S2: Add sodium cyanide solution and water with a mass fraction of 30% into the stirred tank, and stir for 10 minutes at a speed of 800r / min and a temperature of 25°C to obtain a cyanide solution with a mass fraction of 15%. Sodium aqueous solution;

[0037] Step S3: Add the 15% sodium cyanide aqueous solution and liquid chlorine prepared in step S2 into the reactor, and react for 10 minutes at a temperature of 30° C. and a pH value of 3 to obtain cyanogen chloride.

Embodiment 2

[0039] A kind of cyanogen chloride preparation technology that is used for cyanate resin synthesis comprises the steps:

[0040] Step S1: Weigh the following raw materials in parts by weight: 13 parts of sodium cyanide solution and 10 parts of liquid chlorine;

[0041] Step S2: Add sodium cyanide solution and water with a mass fraction of 30% into the stirred tank, and stir for 8 minutes at a speed of 900r / min and a temperature of 28°C to obtain a cyanide solution with a mass fraction of 15%. Sodium aqueous solution;

[0042] Step S3: Add the 15% sodium cyanide aqueous solution and liquid chlorine prepared in step S2 into the reactor, and react for 8 minutes at a temperature of 40° C. and a pH value of 4 to obtain cyanogen chloride.

Embodiment 3

[0044] A kind of cyanogen chloride preparation technology that is used for cyanate resin synthesis comprises the steps:

[0045] Step S1: Weigh the following raw materials in parts by weight: 15 parts of sodium cyanide solution and 12 parts of liquid chlorine;

[0046] Step S2: Add sodium cyanide solution and water with a mass fraction of 30% into the stirring tank, and stir for 10 minutes at a speed of 1000r / min and a temperature of 30°C to obtain a cyanide solution with a mass fraction of 15%. Sodium aqueous solution;

[0047] Step S3: Add the 15% sodium cyanide aqueous solution and liquid chlorine prepared in step S2 into the reactor, and react for 10 minutes at a temperature of 50° C. and a pH value of 4.5 to obtain cyanogen chloride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com