Method for efficiently recovering valuable elements from rare earth molten salt electrolytic slag

A technology of molten salt electrolysis and valuable elements, applied in the direction of process efficiency improvement, alkali metal fluoride, etc., can solve the problems of high energy consumption in vacuum distillation, incomplete defluorination, high distillation temperature, etc., and achieve high comprehensive recovery value , clean separation, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

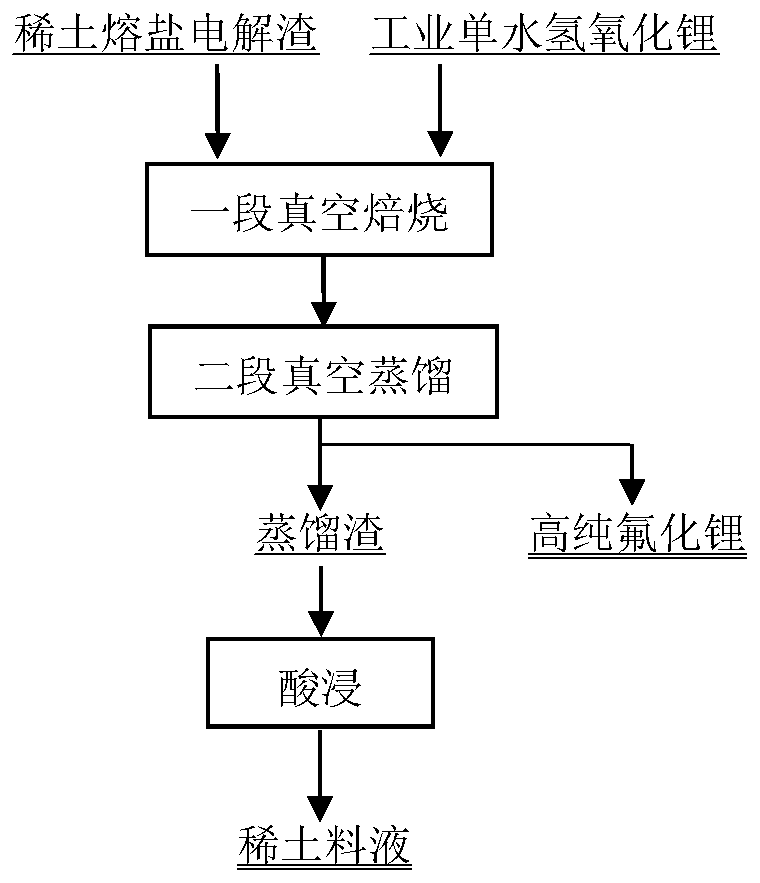

Method used

Image

Examples

Embodiment 1

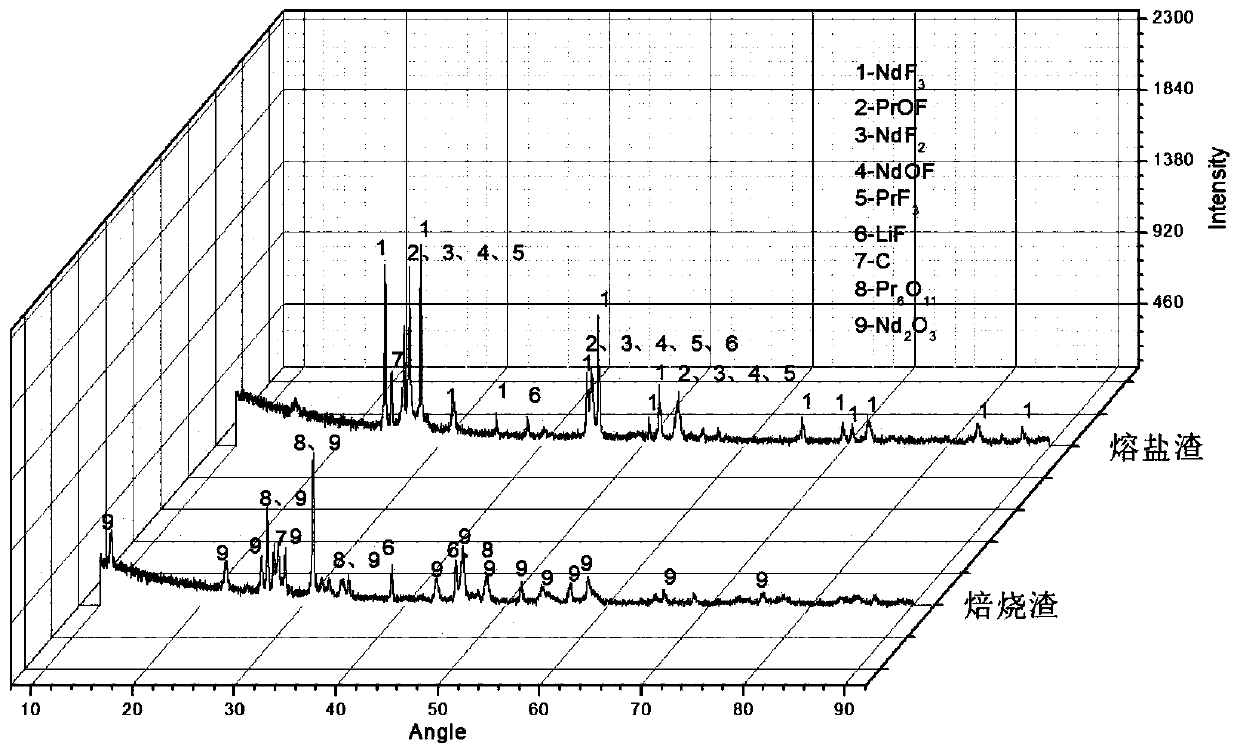

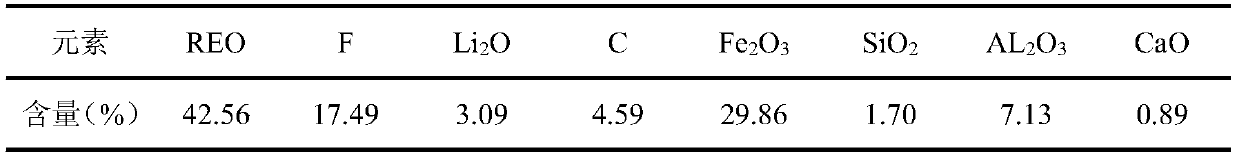

[0024] Take 1 kg of rare earth molten salt electrolytic slag, the molar ratio of rare earth fluoride contained in rare earth molten salt electrolytic slag to industrial lithium hydroxide monohydrate is 1:3, the first stage vacuum roasting temperature is 600°C, the vacuum degree is 5Pa, and the roasting time is 2h; the second stage vacuum The distillation temperature was 850° C. and the vacuum degree was 30 Pa. After vacuum distillation for 2 hours, 0.237 kg of lithium fluoride condensate and 0.866 kg of distillation residue were obtained. The chemical composition of the lithium fluoride condensate was shown in Table 2. The F content in the distillation slag is <0.01%, the rare earth content (calculated as REO) is 47.97wt%, the fluorine recovery rate in the vacuum distillation process is 99.3%, and the fluorine recovery rate=fluorine content in lithium fluoride / rare earth molten salt electrolytic slag Medium fluorine content.

[0025] Table 2 Chemical composition of lithium flu...

Embodiment 2-5

[0029] The rare earth molten salt electrolytic slag was treated according to the method of Example 1, except that the molar ratio of the rare earth fluoride contained in the rare earth molten salt electrolytic slag of the first stage of vacuum roasting was different from that of industrial lithium hydroxide monohydrate. The specific parameters and test results are shown in Table 3.

[0030] Table 3 embodiment 1-5 test result

[0031]

Embodiment 6

[0033] Take 10kg of rare earth molten salt electrolytic slag, the molar ratio of rare earth fluoride contained in rare earth molten salt electrolytic slag to industrial lithium hydroxide monohydrate is 1:3.1, the first stage vacuum roasting temperature is 300°C, the vacuum degree is 5Pa, and the roasting time is 2h; the second stage vacuum The distillation temperature was 900° C., the vacuum degree was 50 Pa, and after vacuum distillation for 1 hour, 2.385 kg of lithium fluoride condensate and 8.745 kg of distillation residue were obtained. The chemical composition of the lithium fluoride condensate is shown in Table 4. The F content in the distillation residue is <0.01%, the rare earth content (calculated as REO) is 48.67wt%, and the fluorine recovery rate in the vacuum distillation process is 99.8%.

[0034] The distillation residue was stirred and leached for 2 hours under the conditions of hydrochloric acid concentration 4mol / L / , acid leaching pH=0.5, and acid leaching temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com