Hybrid Air Separation Method with Noncryogenic Preliminary Enrichment and Cryogenic Purification Based on a Single Component Gas or Liquid Generator

a gas or liquid generator and hybrid air separation technology, which is applied in the direction of separation processes, lighting and heating apparatus, liquefaction, etc., can solve the problems of low purity, low purity, and low efficiency of liquid use, and achieve no more than 99% nitrogen and 93% oxygen purity, and the effect of less column cross section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

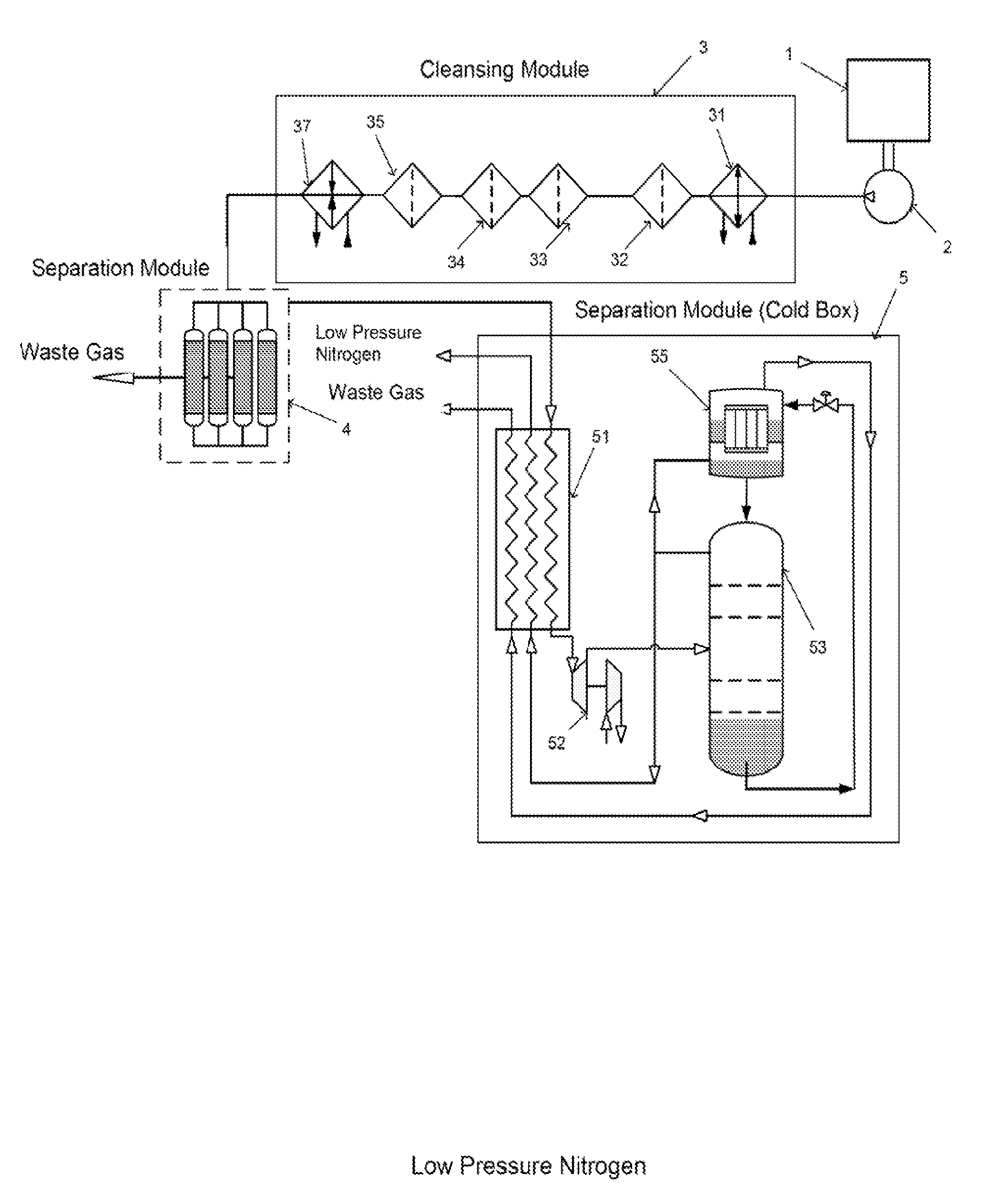

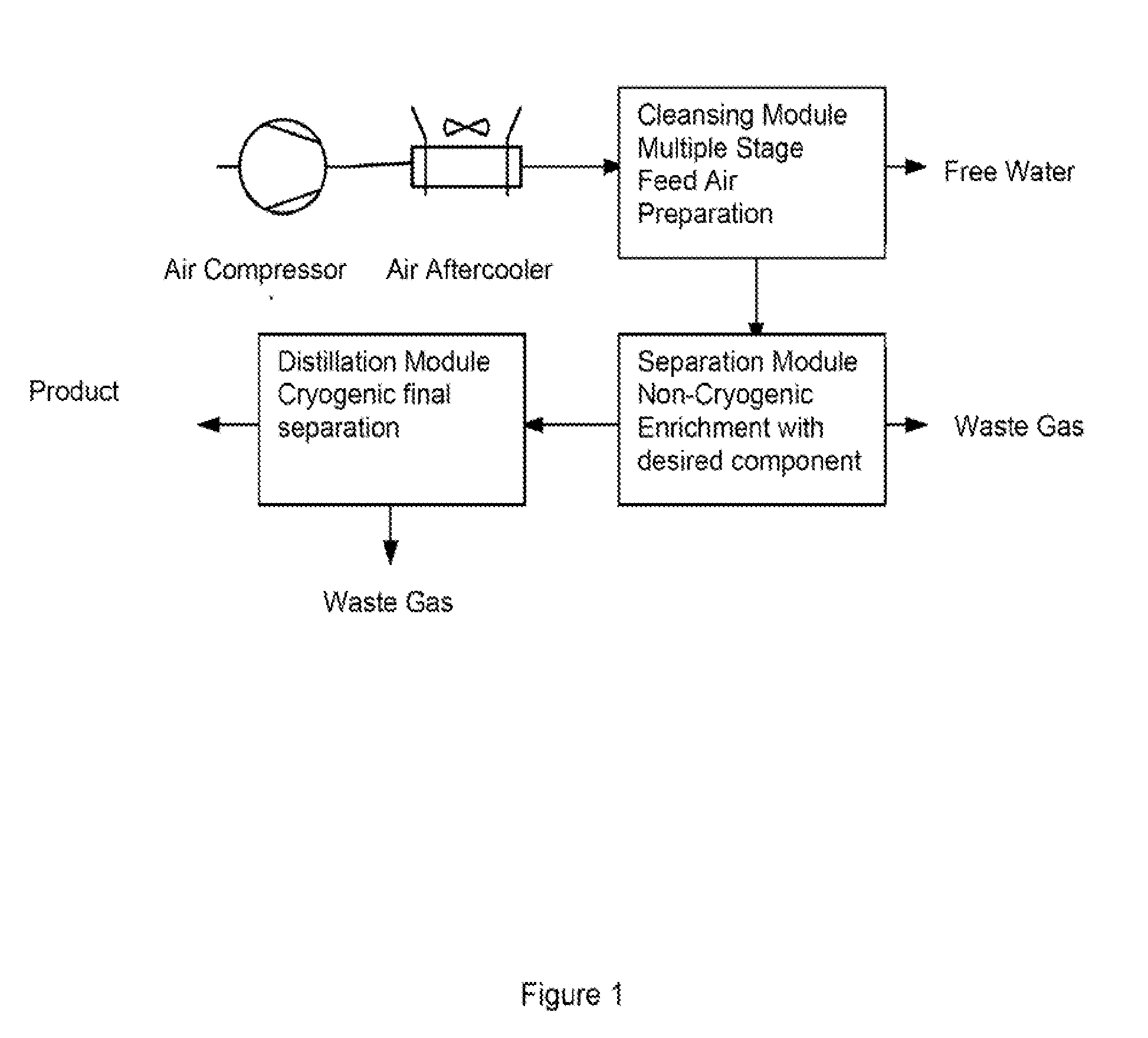

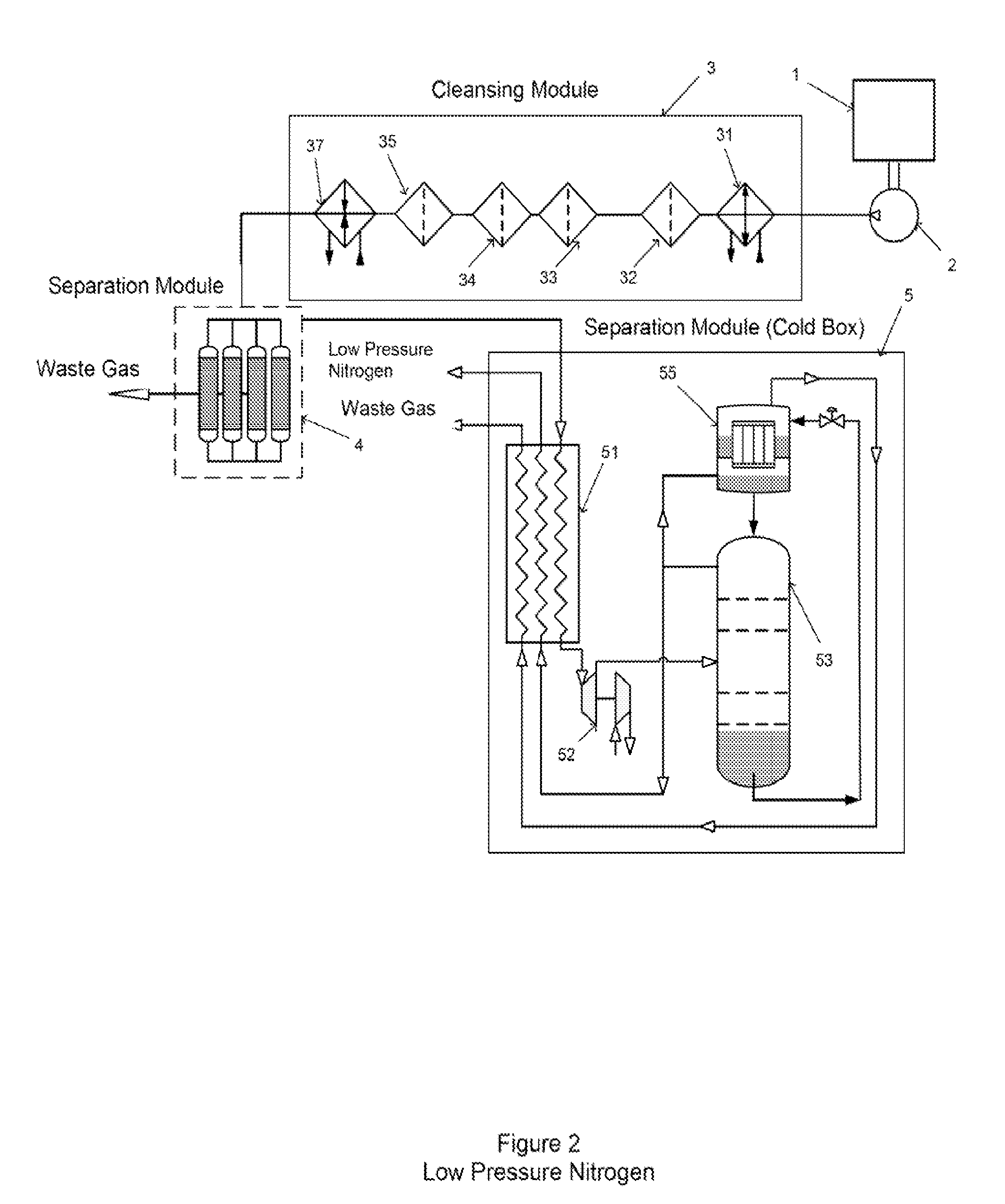

[0024]The illustrated general embodiment of the invention shown in FIG. 1 is a method for producing and delivering high purity single component gas such as nitrogen or oxygen at high pressures of up to 15,000 psig using an apparatus with a significantly lower profile of no more than 20 feet of overall height than would otherwise be required. A conventional cryogenic gas plant distillation unit (a.k.a. cold box) is supplemented at the front end by using a separation module with a non-cryogenic enrichment system not only to clean the air of water and carbon dioxide, as is normally required by the cryogenic distillation cycle, but additionally, to significantly enrich the feed flow with the desired component by removing a significant amount of the undesired component. The removal of the undesired component before the cryogenic process located in the distillation module permits the distillation column to be significantly shorter than otherwise would be required. This in turn reduces the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com