Recovery process and apparatus for solid state metal sodium waste residue

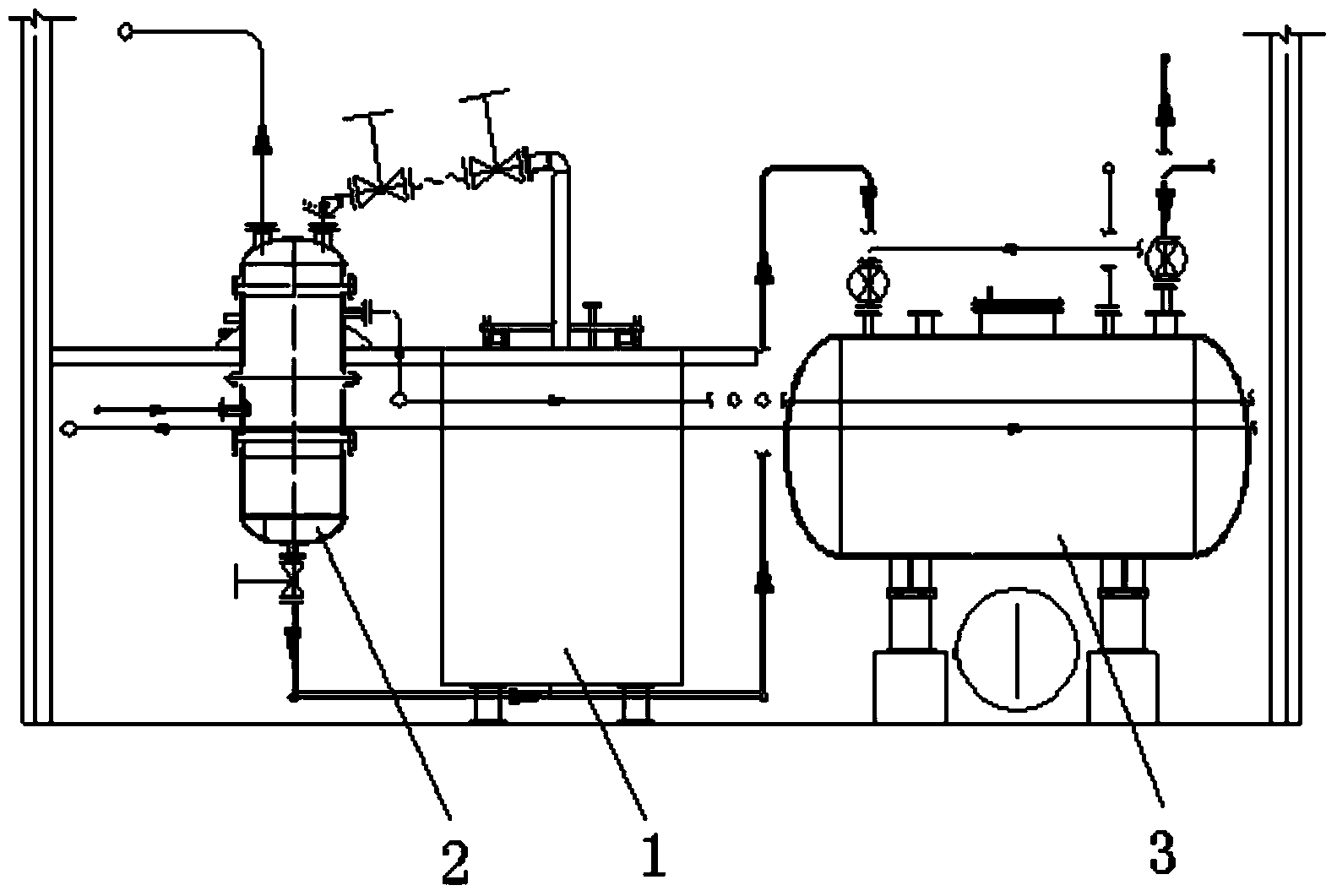

A recovery device and metal sodium technology are applied in the field of solid metal sodium waste slag recovery processes and devices, which can solve problems such as potential safety hazards and increase in sodium slag inventory, and achieve the effects of improving recovery rate, high output rate, and safe and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

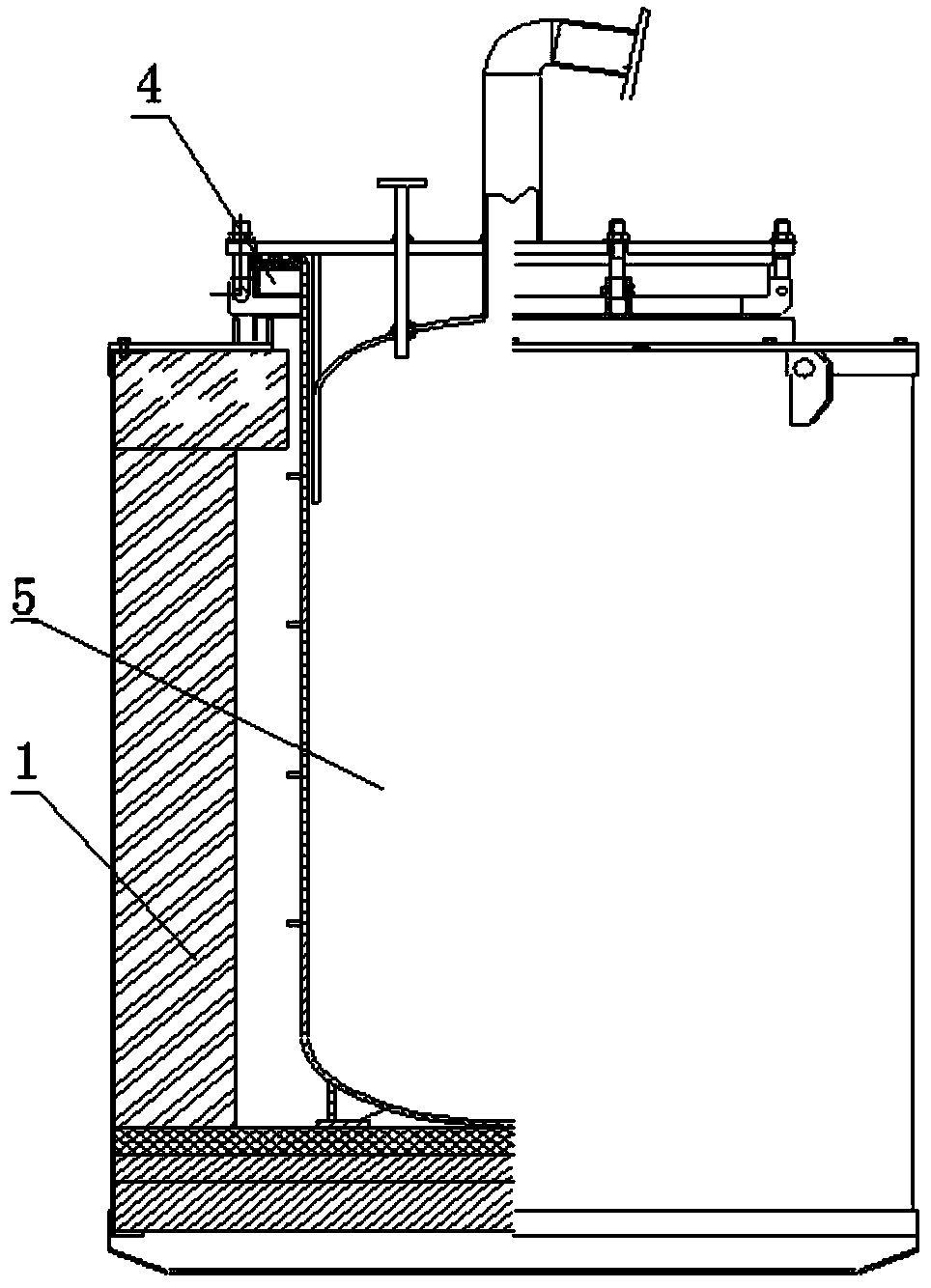

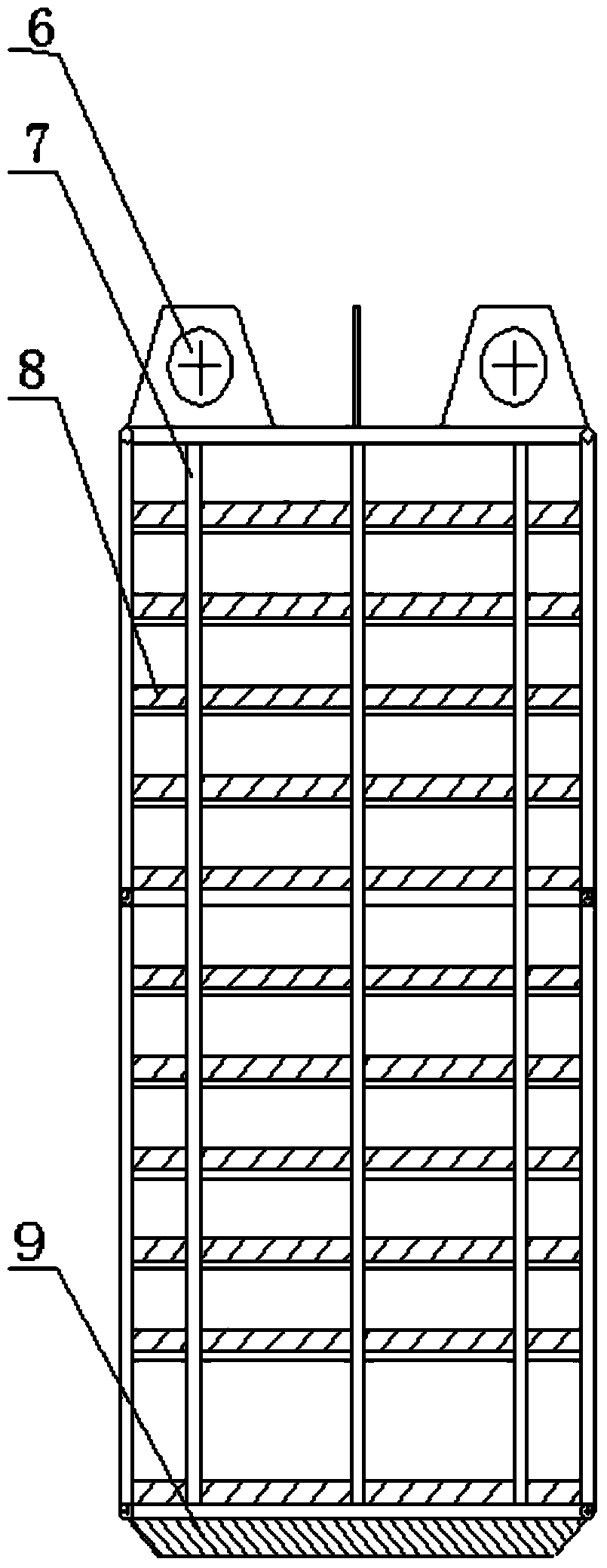

[0021] 1. The high-temperature vacuum distillation kettle 5 has a diameter of 800mm and a charge of 120kg;

[0022] 2. Heating time is 1 hour;

[0023] 3. Constant temperature distillation time 8 hours;

[0024] 4. Distillation temperature is 650℃;

[0025] 5. The vacuum pump must be continuously turned on during distillation, and the vacuum pressure is -0.09MPa (gauge pressure).

[0026] First, add the solid metal sodium waste slag to the high-temperature vacuum distillation kettle 5, and then evacuate the air in the vacuum distillation system until the negative pressure is reached. The heating furnace 1 is heated to obtain sodium vapor and the distillation starts. When the distillation is completed, the heating furnace 1 is turned off and the argon gas is turned on. The inlet valve is used to relieve the pressure. After the pressure is relieved, the refined sodium storage tank 3 is opened to release sodium, and the high-temperature vacuum distillation kettle 5 is taken out as a whole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com