Sponge titanium and sponge zirconium reduction distillation equipment

A distillation equipment and zirconium sponge technology, which is applied in the field of magnesium chloride discharge produced in the reduction distillation process of sponge titanium (zirconium, hafnium), can solve the problems of difficulty in taking out sponge titanium, easy leakage of welding parts, etc., and achieve easy removal, easy production, The effect of easy craft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

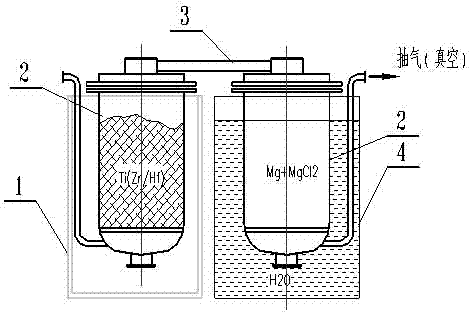

[0013] The production of sponge titanium and sponge zirconium (hafnium) is divided into two processes: reduction and distillation, and the reactor is required to have two functions; during the reduction process, the reactor is used as a reduction reactor, and during distillation, it is used as a cooler to meet the requirements of interchangeability.

[0014] The reduction distillation equipment of the present invention comprises two reduction reactors 2, wherein one reduction reactor 2 is arranged in the reduction distillation furnace 1 as a reduction operation, and the other reduction reactor 2 is arranged in the cooler 4 as condensate collection After a cycle is over, it is converted into a reduction distillation furnace and converted into a reduction reactor; the upper ends of the two reduction reactors 2 are connected through the channel heater 3 provided.

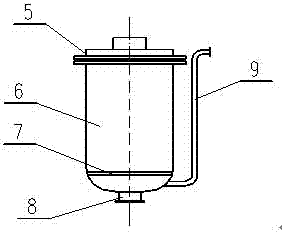

[0015] The reduction reactor 2 includes a reactor cover 5 , a reactor cylinder 6 and a filter plate 7 , and a product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com