Device and method for oxidizing low carbon olefin to prepare low carbon epoxy hydrocarbon compound

A technology of carbon epoxy hydrocarbons and low carbon olefins, which is applied in the field of devices for producing low carbon epoxy hydrocarbons, can solve the problems of large fluctuation range of reaction temperature, inability to remove reaction heat in time, difficulty in solvent methanol recovery, etc., to achieve reaction Small temperature fluctuation range, flexible control, and environment-friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

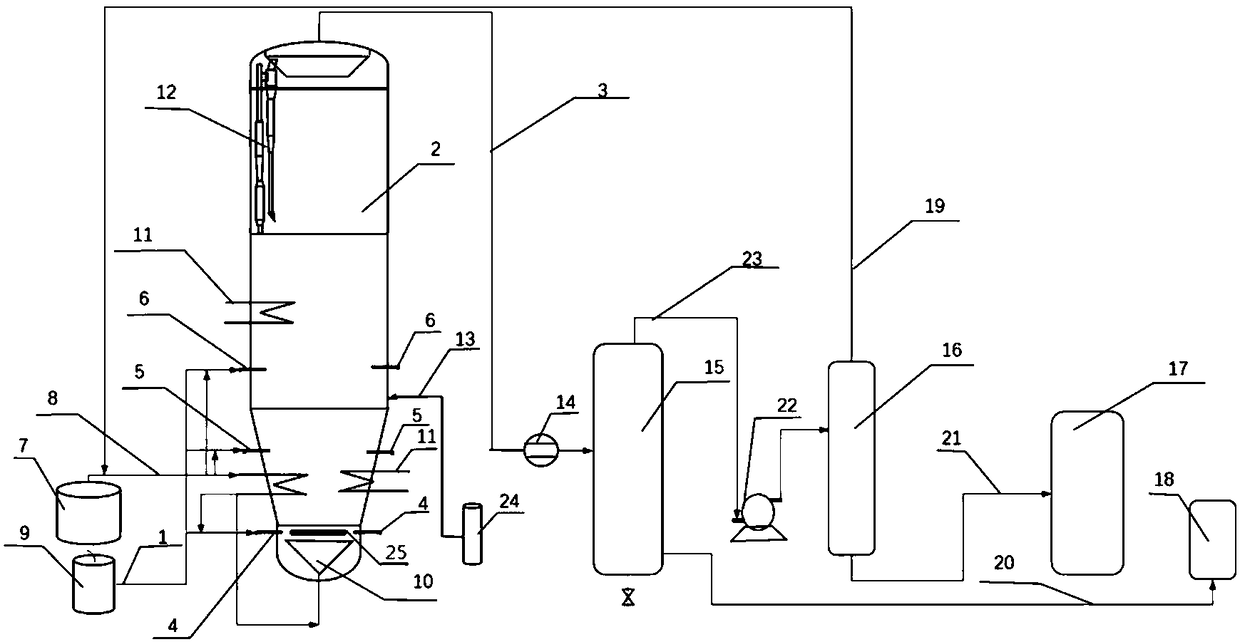

[0068] A method for generating low-carbon epoxy hydrocarbons by oxidation of low-carbon olefins, the steps are:

[0069] 1) Send the first part of low-carbon olefin raw materials into the reactor from the bottom of the reactor, and fluidize the catalyst in the pre-fluidization section of the reactor to make the catalyst in a dense-phase fluidized state. After mixing the second part of low-carbon olefin raw materials with hydrogen peroxide Atomized into the reactor through multi-stage atomizing nozzles, the distribution ratio of the first part of light olefins and the second part of low-carbon olefins is 2:1, atomized through multi-stage atomizing nozzles, and fluidized in the dense phase circulation of the reactor In the section, under the action of TS-1 molecular sieve catalyst, the reaction temperature is 60°C, the reaction pressure is 0.08Mpa, the weight ratio of catalyst to hydrogen peroxide is 5:1, and the molar ratio of low carbon olefins to hydrogen peroxide is 5 Carry ...

Embodiment 2

[0074] In step (1), the distribution ratio of the first part of low-carbon olefins and the second part of low-carbon olefins is 5:1, and the reaction temperature of low-carbon olefins and hydrogen peroxide is 70°C and the reaction pressure is 0.10Mpa;

[0075] In the step (3), the temperature of the compressor is 35°C, the pressure is 1.5Mpa, the temperature at the top of the fractionating tower is 50°C, the temperature at the bottom of the tower is 100°C, and the pressure of the fractionating tower is 1.3Mpa; the light olefin is ethylene.

[0076] Others are with embodiment 1.

Embodiment 3

[0078] In step (1), the distribution ratio of the first part of low-carbon olefins and the second part of low-carbon olefins is 10:1, and the reaction temperature of low-carbon olefins and hydrogen peroxide is 100 ° C, the reaction pressure is 0.12Mpa, and the weight ratio of catalyst to hydrogen peroxide is 15: 1. The molar ratio of light olefins to hydrogen peroxide is 9:1;

[0079] Compressor temperature is 45 ℃ in the step (3), and pressure is 2.0Mpa, and fractionation tower top temperature is 55 ℃, and tower bottom temperature 110 ℃, and fractionation tower pressure is 1.6Mpa; Getting heat medium is hydrogen peroxide.

[0080] Others are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com