Nano composite polyaluminum ferric chloride flocculant and preparation method thereof

A polyaluminum chloride and nanocomposite technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of unstable product performance, high chromaticity residue, and high processing cost, and achieves overcoming aluminum ion residue, fast sedimentation, Advanced craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 90 grams of aluminum trichloride, 10 grams of ferric chloride, and 500 grams of water into a three-necked flask (the weight-number ratio of water does not meet the scope defined in the claims), heat up to 70°C and stir at a stirring speed of 350r / min, after the dissolution is complete, make 40 grams of sodium hydroxide into a 2mol / L solution and slowly add it dropwise into the three-necked flask, continue to heat up to 100°C after the drop, stir at constant temperature for 5 hours, and then pour the liquid into the ultrasonic cleaner (manufactured by Hangzhou Frante Ultrasonic Technology Co., Ltd., model: FR10 series), add 1 gram of 100-mesh graphene to 10 grams of 20% hydrochloric acid for acidification treatment, filter it out after 12 hours and add it to the ultrasonic cleaning machine , turn on the ultrasonic cleaning machine, control the ultrasonic frequency at 100hz, pour out after mixing for half an hour, and then ripen for 24 hours to obtain the nanocomposit...

Embodiment 2

[0030] Add 50 grams of aluminum trichloride, 50 grams of ferric chloride, and 650 grams of water into the three-necked flask, heat up to 60°C and stir at a stirring speed of 300r / min. After the dissolution is complete, configure 30 grams of sodium hydroxide to 2mol After dropping the solution, slowly add it dropwise to a three-necked flask, continue to heat up to 90°C, stir at a constant temperature for 3 hours, then pour the liquid into an ultrasonic cleaner, add 5 grams of 120-mesh graphene to 30 grams of 20% concentration Perform acidification treatment in hydrochloric acid, filter out after 12 hours and add to the ultrasonic cleaner, turn on the ultrasonic cleaner, control the ultrasonic frequency at 50hz, pour it out after mixing for one hour, and then mature for 20 hours to obtain nanocomposite polyaluminum chloride Iron flocculant, the product obtained in this embodiment is represented by NO.2.

Embodiment 3

[0032] Add 90 grams of aluminum trichloride, 10 grams of ferric chloride, and 800 grams of water into the three-necked flask, heat up to 50°C and stir at a stirring speed of 200 r / min. After the dissolution is complete, configure 35 grams of sodium hydroxide to 2mol After dropping the solution, slowly add it dropwise to the three-necked flask, continue to heat up to 90°C, stir at constant temperature for 2 hours, pour the liquid into the ultrasonic cleaning machine, add 5 grams of 200-mesh nano-silica to 20 grams of concentration 20 % hydrochloric acid for acidification treatment, filtered out after 12 hours and added to the ultrasonic cleaning machine, turned on the ultrasonic cleaning machine, controlled the ultrasonic frequency at 80hz, poured it out after 45 minutes, and then aged for 24 hours to obtain nanocomposite polymeric chloride Aluminum-iron flocculant, the product obtained in this embodiment is represented by NO.3.

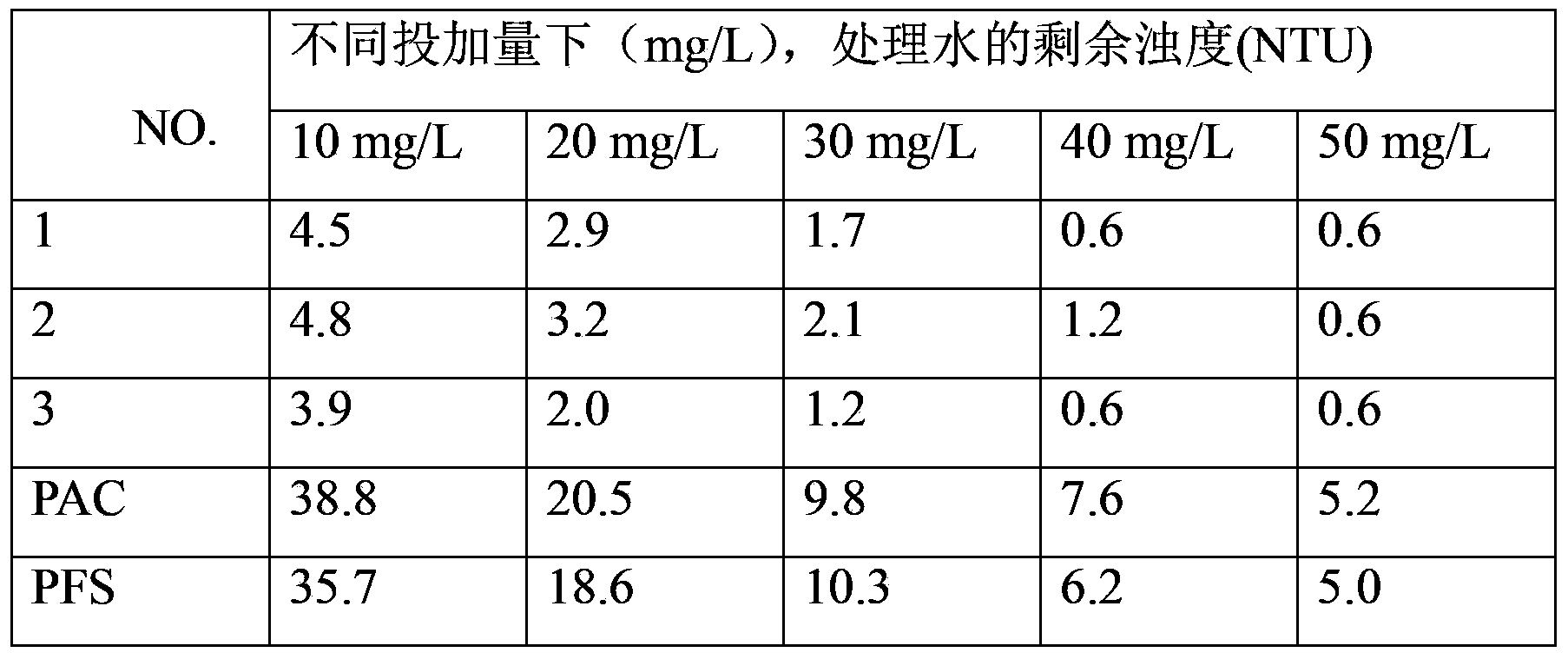

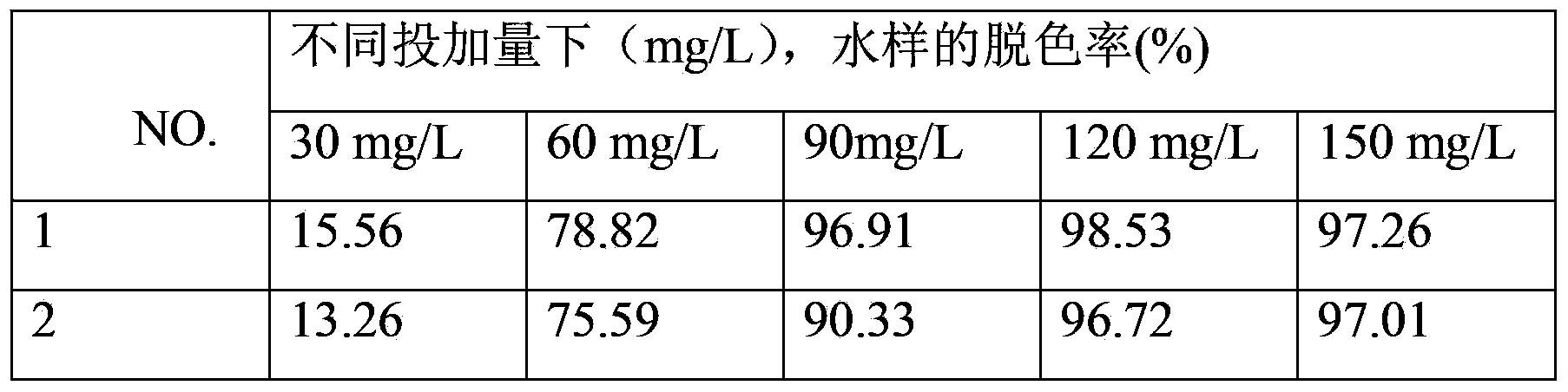

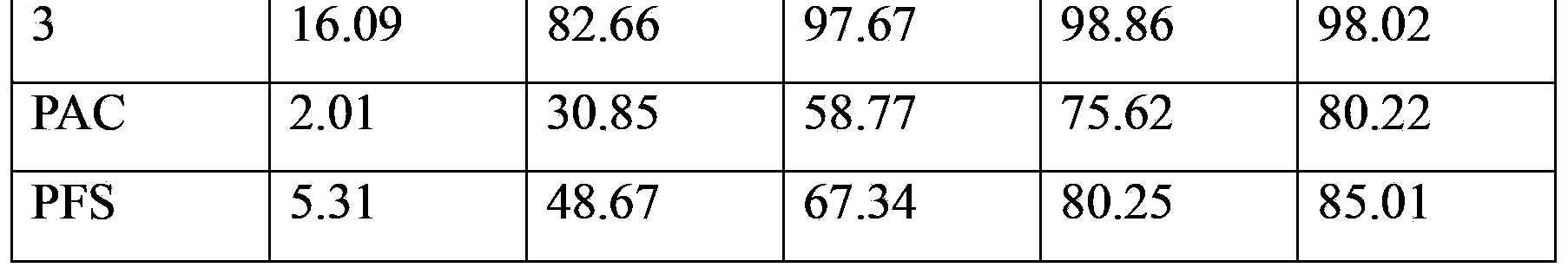

[0033] The nanocomposite polyaluminium-ferric c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com