Self adhesive and high molecule self adhesive water-proof coil and producing process

A self-adhesive waterproof membrane and manufacturing process technology, applied in the direction of adhesive, adhesive type, asphalt material adhesive, etc., can solve the problems of large carcass shrinkage, complicated process, difficult to dissolve, etc., and achieve easy mixing and modification , The glue mixing process is simple, and the effect of enhancing the adsorption force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0077] Specific embodiment 1: self-adhesive glue, this self-adhesive glue is made up of asphalt, SBS rubber, tackifier, SIS rubber, maleic anhydride, aluminum chloride, thiuram, magnesium chloride, calcium silicate. The selected materials are as follows:

[0078] Select No. 90 high-quality heavy traffic asphalt produced by Maoming Petrochemical Company, SBS 792 produced by Yueyang Petrochemical Company Rubber Factory, Kraton SIS 1105, tackifier produced by Maoming Petrochemical Plant, maleic anhydride, aluminum trichloride, thiuram, and magnesium chloride , Calcium silicate. Put it into the mixing tank successively, and grind it fully for later use.

[0079] The proportioning examples of each component by weight ratio are as follows:

[0080]

[0081] Nine

47.2%

7%%

6%

13%

0.3%

0.5%

0.8%

0.2%

25%

ten

44.5%

6%

7%

11%

0.1%

0.4%

0.8%

0.2%

30%

[0...

specific Embodiment 2

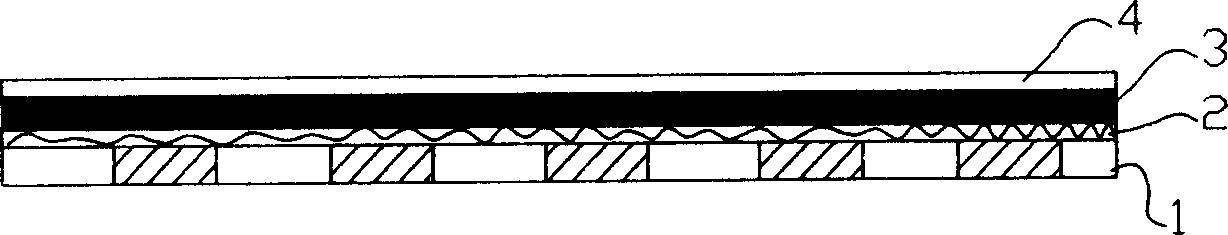

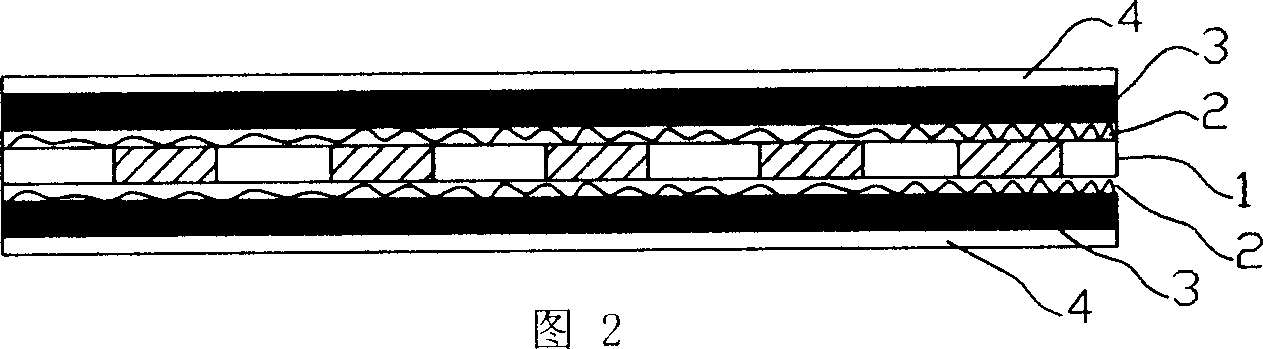

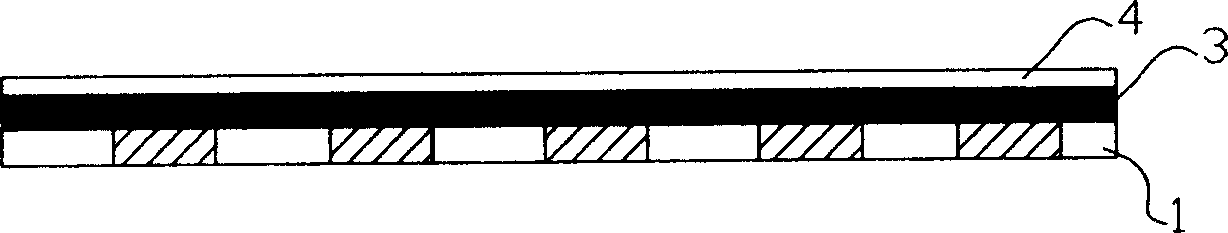

[0092] Specific embodiment 2: as shown in Figure 2, a kind of macromolecule self-adhesive waterproof roll material, it adopts the self-adhesive of specific embodiment 1 to make, is made of main material layer 1, two layers of self-adhesive that are made of self-adhesive The adhesive layer 3 and two isolation layers 4 are formed. Two layers of self-adhesive layers are respectively compounded on the upper and lower surfaces of the main material layer, and two layers of isolation layers are respectively compounded on the outer surfaces of the two self-adhesive layers; the main material layer is composed of a synthetic resin sheet with a reinforcing material layer or a The fiber reinforced material layer consists of synthetic rubber sheets. Both outer surfaces of the body material layer have layers of fiber reinforcement material 2 .

[0093] like Figure 4 As shown, the main body material layer can also be made of a synthetic resin sheet or a synthetic rubber sheet, and the sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com