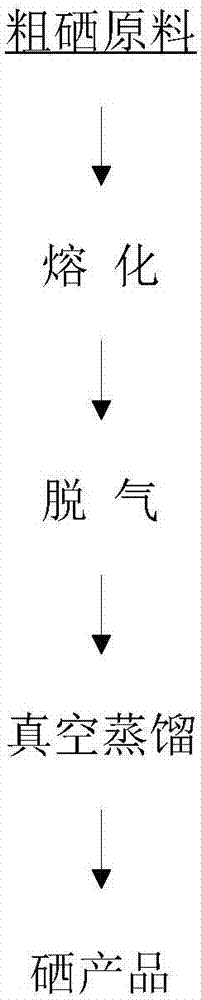

Vacuum refining and purifying method for coarse selenium material

A vacuum refining and material technology, applied in binary selenium/tellurium compounds, elemental selenium/tellurium, etc., can solve the problems of low output of a single equipment, long purification process, poor on-site operating environment, etc., to reduce product pollution, Good working environment and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Step 1. Process the crude selenium materials produced in the process of recovering gold and silver by 300Kg copper electrolytic anode mud (main components: 92.35% of selenium, 0.01% of tellurium, 0.73% of lead, 0.29% of water, and others are copper, iron and other salts. Class) Put it into a closed melting electric furnace at one time, and heat the electric furnace to 230℃ to melt the crude selenium material. After the crude selenium material in the electric furnace is completely melted, the electric furnace is heated to 260°C for degassing. In the degassing process, the melting electric furnace is vacuumed with a circulating pump, and the vacuum of the melting electric furnace is maintained at 500~4000Pa. The selenium melt is stirred and stirred for 2 hours to obtain a density of 4.2g / cm 3 Of crude selenium melt.

[0040] Step 2. Put the melted and degassed crude selenium melt into a graphite crucible, place the graphite crucible in a vacuum distillation furnace, and vacu...

Embodiment 2

[0043] Step 1. Treat 500Kg copper electrolytic anode slime to the crude selenium material produced during the sulfation roasting process (the main components are: selenium 82.7%, tellurium 0.87%, lead 1.18%, water 28.53%, and the others are copper, iron and other salts. ) Stably add it to a closed melting electric furnace at a rate of 14g / s, slowly raise the temperature of the electric furnace to 300°C to melt the crude selenium material. When melting, use a vacuum pump to vacuum the melting electric furnace while continuously stirring the crude selenium material. After the 500Kg crude selenium material in the airtight melting electric furnace is completely melted, the electric furnace is heated to 350℃ for degassing. During the degassing process, the melting electric furnace is vacuumed with a vacuum pump, and the vacuum of the melting electric furnace is controlled to 1000~5000Pa. While stirring the selenium melt, stirring for 1 hour to obtain a density of 4.5g / cm 3 Of crude s...

Embodiment 3

[0048] Step 1. The crude selenium materials produced in the process of recovering gold and silver by treating 650Kg copper electrolytic anode mud (the main components are: selenium 76.04%, tellurium 5.08%, lead 8.78%, water 28.12%, and others are copper, iron and other salts) Class) Add 30Kg of materials to the closed melting electric furnace at a rate of one-time addition of 30Kg materials every 20 minutes. After the initial feeding, the furnace is heated to 350°C to melt the crude selenium materials while continuously stirring the crude selenium materials. After all 650Kg crude selenium materials are put into the closed melting electric furnace, and the materials are completely melted, the electric furnace is heated to 400°C for degassing. During the degassing process, the melting electric furnace is vacuumed with a vacuum pump, and the vacuum degree of the melting electric furnace is controlled to 2000~10000Pa At the same time, the selenium melt is stirred, and the density is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com