Micron-level fine particle diamond synthesis process

A synthesis process and diamond technology, applied in the field of micron-scale fine-grained diamond synthesis process, can solve the problems of mechanical properties, no crystal shape, limited application range, etc., and achieve the effect of less impurities, complete crystal plane, and consistent crystal shape

Active Publication Date: 2013-02-20

山东昌润钻石股份有限公司

View PDF4 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the particle size of domestically synthesized fine-grained diamond is generally greater than 200 mesh, and the proportion of single crystal is low, generally 30%-40%; fine-grained crystals smaller than 200 mesh are generally obtained by crushing coarse-grained diamond. It is time-consuming and labor-intensive, and the obtained crystals do not have a complete crystal form, so that their mechanical properties are also seriously affected, and ultimately their application range is limited

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

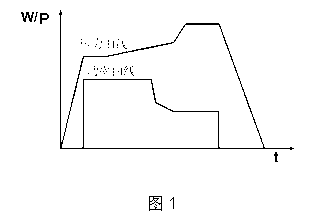

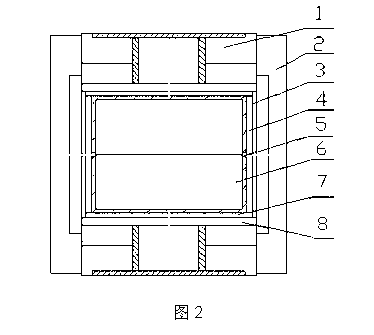

Login to View More Abstract

The invention provides a micro-level fine particle diamond synthesis process. The micro-level fine particle diamond synthesis process comprises the steps of mixing graphite powder and Fe-based alloy catalyst powder according to the weight ratio of 8:(5-7), then carrying out isostatic pressing and vacuum process and then carrying out compression molding on the mixture in a four-column press machine, putting a core column into a diamond synthesis block, and putting the diamond synthesis block into a cubic press to carry out synthesis, wherein the practical synthesis pressure is 6.1-6.6GPa, the synthesis temperature is 1000-1100 DEG C, and the practical synthesis pressure and the synthesis temperature are finished respectively by utilizing a control pressure curve and a power curve. According to the micro-level fine particle diamond synthesis process disclosed by the invention, the synthesized micron-level fine particle diamonds have the characteristics of large nucleation amount, short growth time and the like, products conform to an artificial diamond national standard and have consistent crystal forms, smooth crystal surfaces, a few of impurities and high hot punching values, the particle granularity of 270 / 325 and 325 / 400 is a peak value, a single crystal ratio reaches to 70-80%, and the micro-level fine particle diamond synthesis process can effectively meet the field of high-grade grinding tools and the like with high requirements on particle granularity.

Description

technical field [0001] The invention relates to the field of diamond synthesis, in particular to a micron-scale fine particle diamond synthesis process. Background technique At present, with the continuous progress of synthesis technology, the quality of synthetic diamond single crystal is getting higher and higher. In the use of diamond tools, artificial micron-sized fine-grained diamond is a new type of ultra-hard ultra-fine abrasive, which is widely used in the fields of machinery, electronics, aerospace and military industry, and is ideal for grinding and polishing cemented carbide, ceramics, gemstones, optics, etc. Ideal material for high hardness materials such as glass. At present, the particle size of domestically synthesized fine-grained diamonds is generally greater than 200 mesh, and the proportion of single crystals is low, generally 30%-40%; fine-grained crystals smaller than 200 mesh are generally obtained by crushing coarse-grained diamonds. It is time-co...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01J3/06

Inventor 林秀峰白云岗林树忠

Owner 山东昌润钻石股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com