Patents

Literature

41results about How to "With impurity removal function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

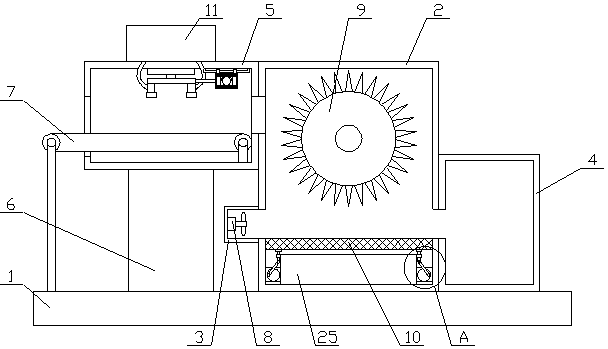

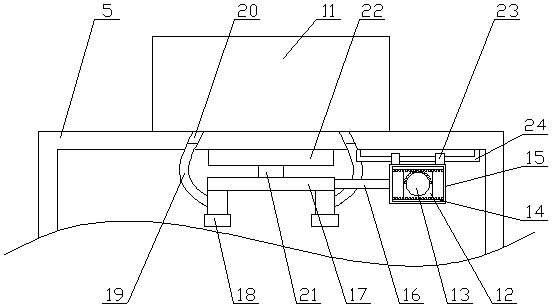

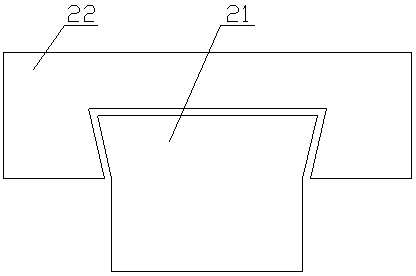

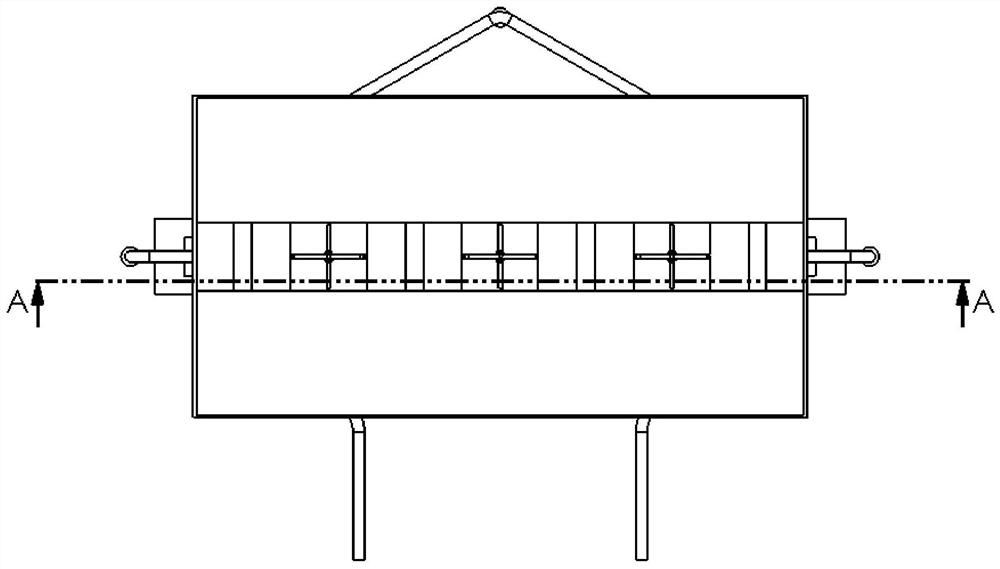

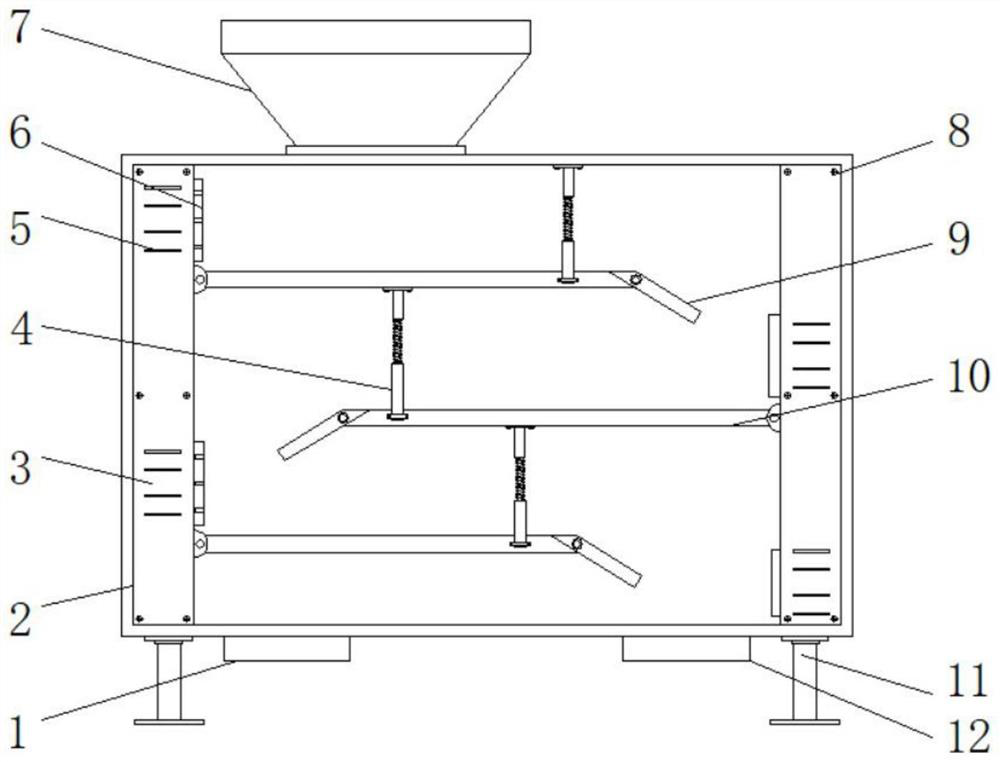

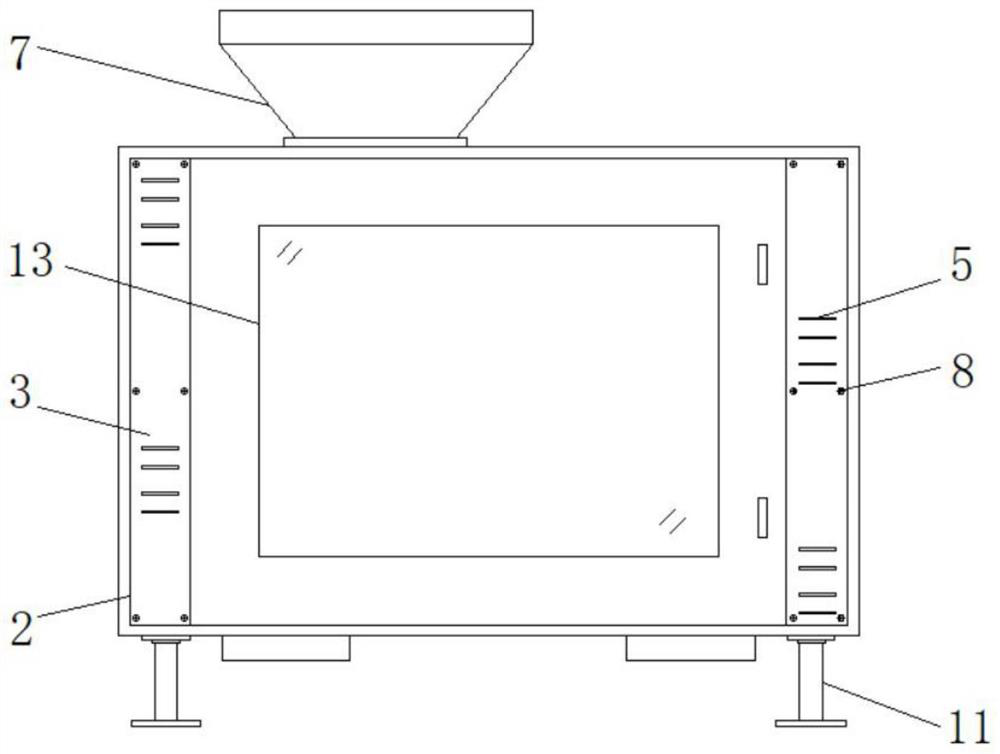

Grain thresher with impurity removing function

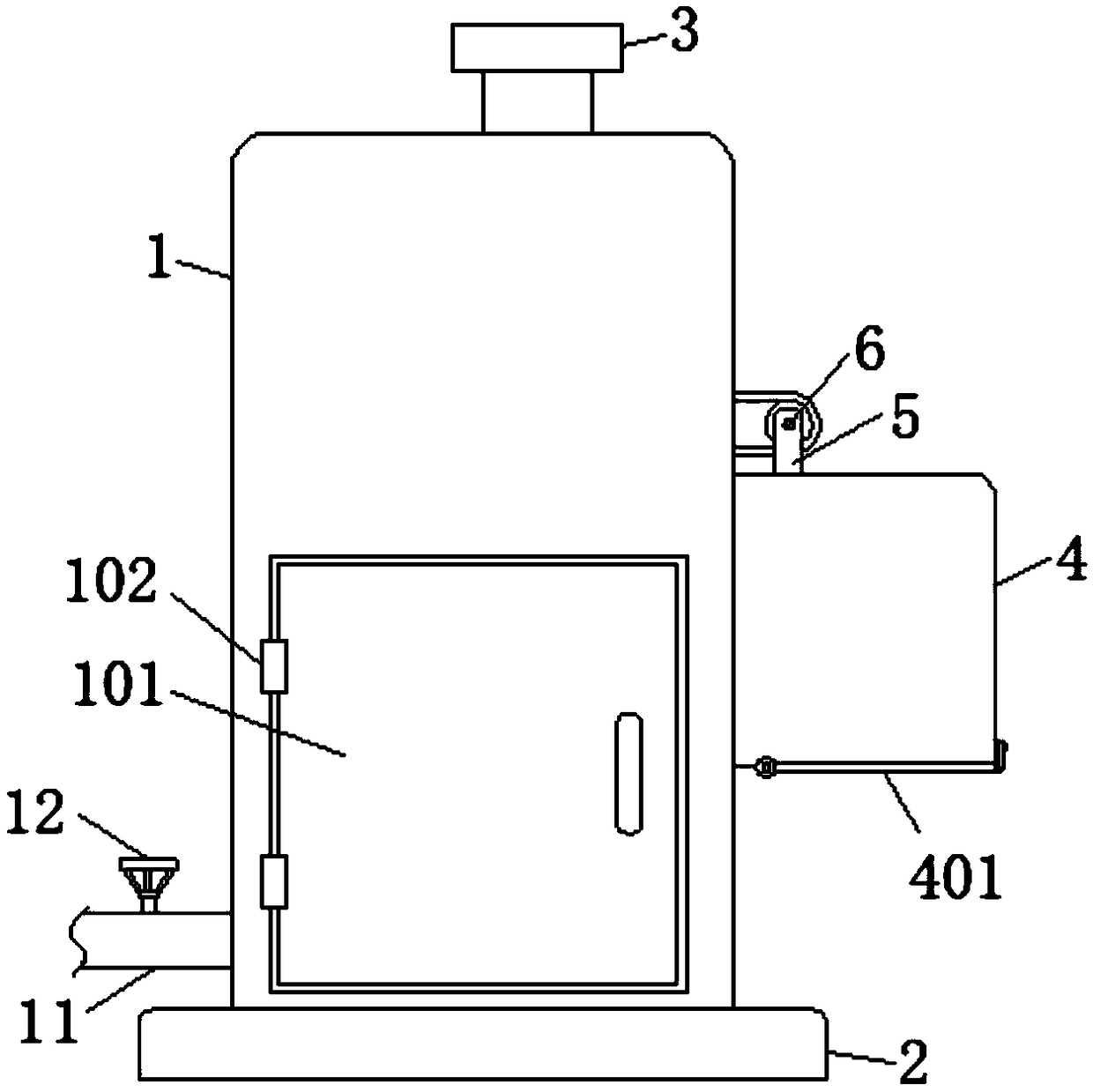

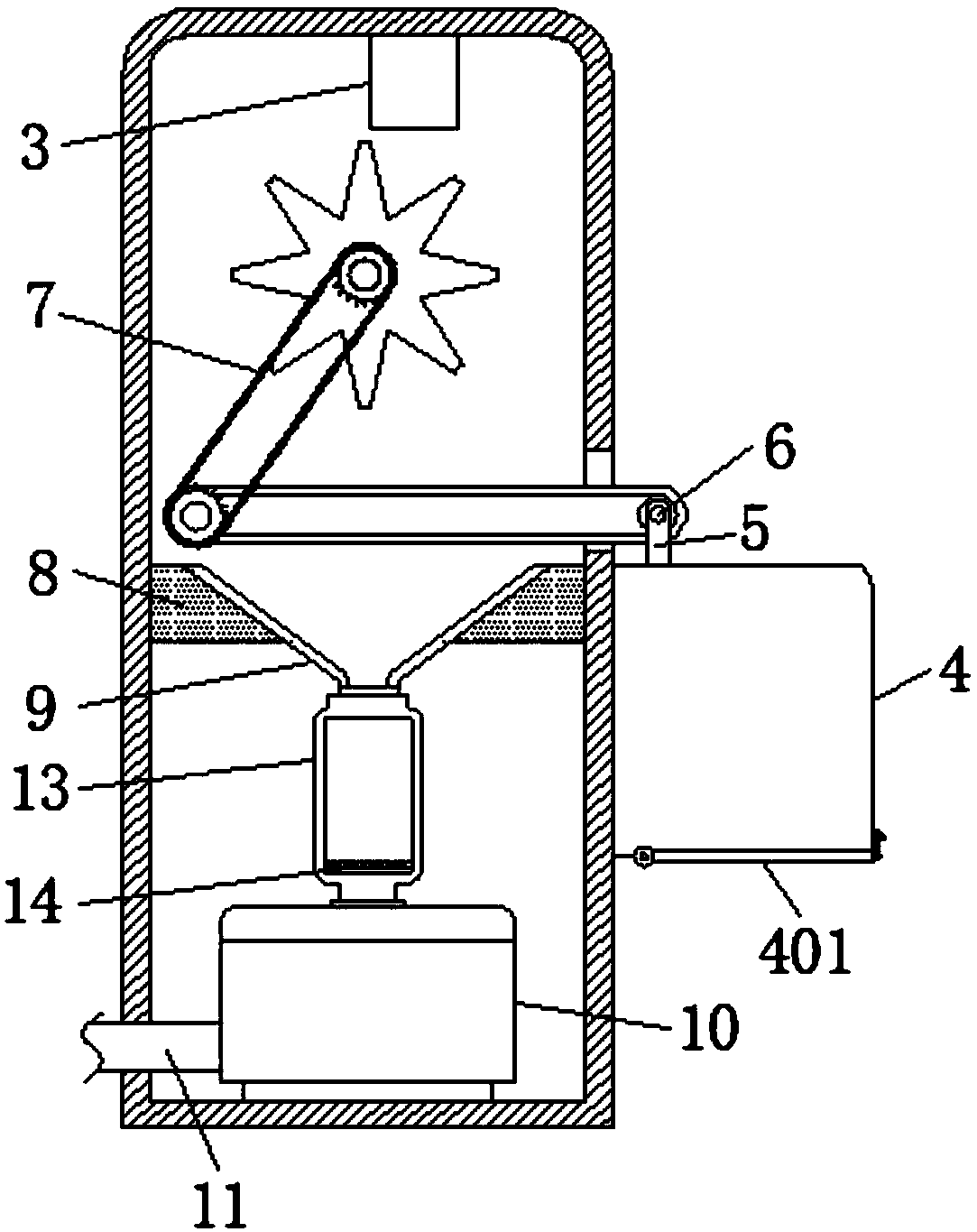

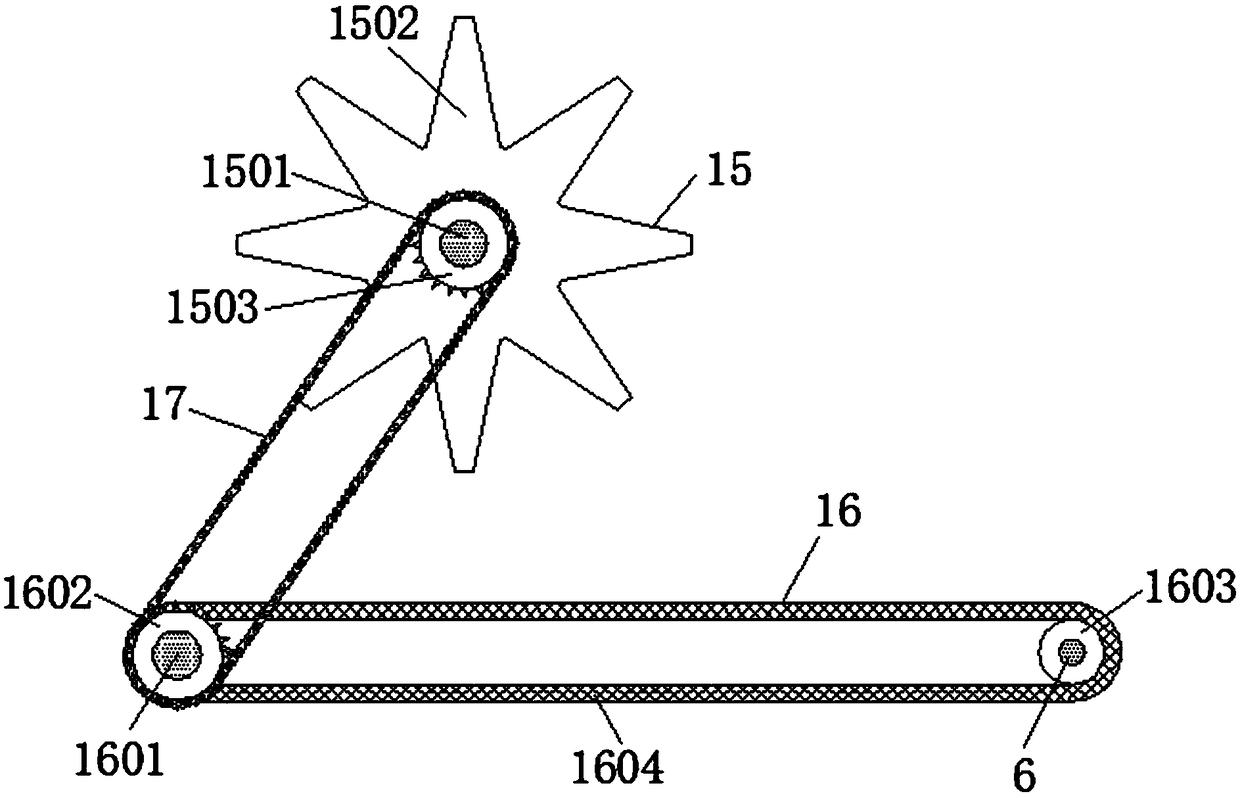

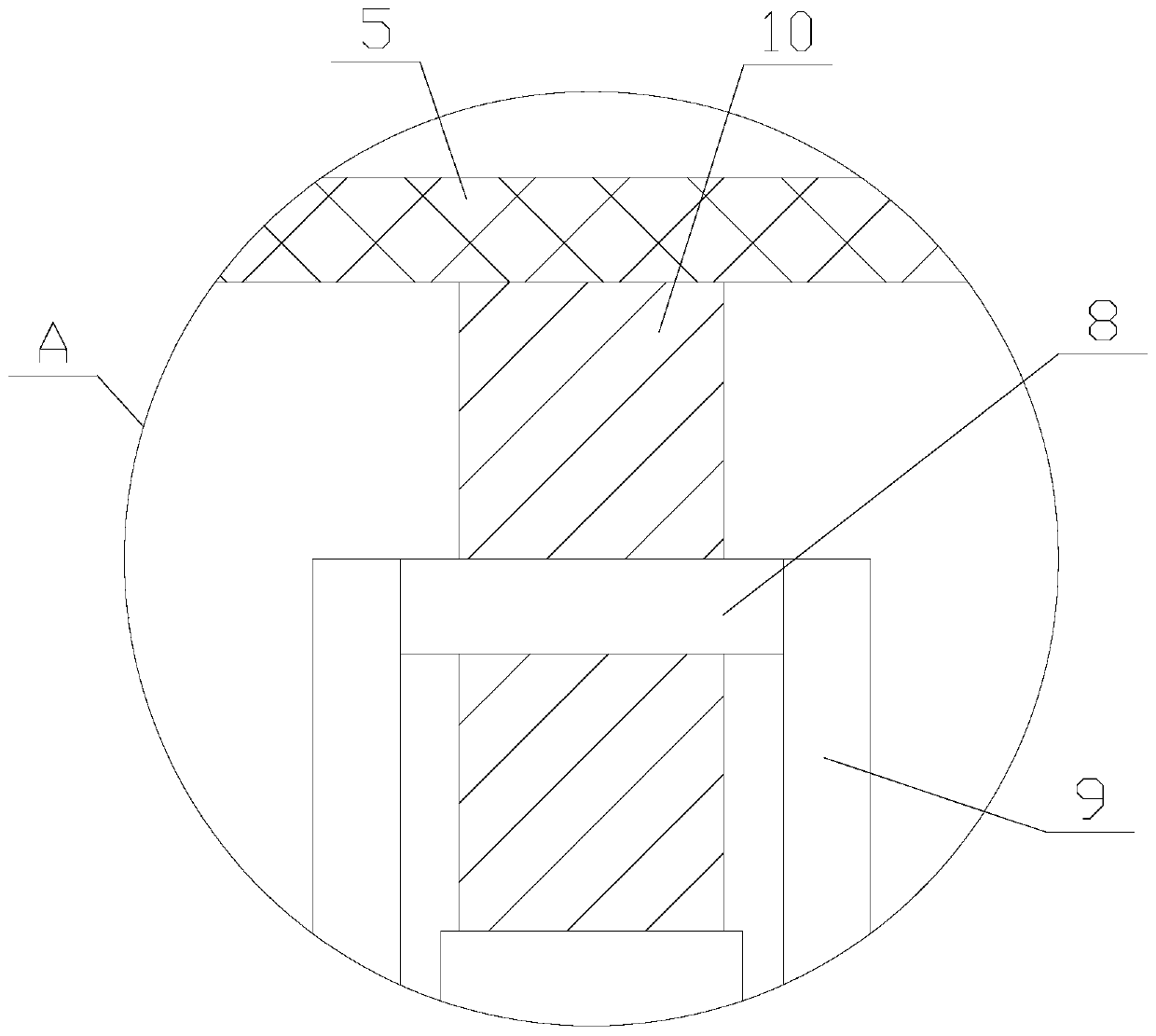

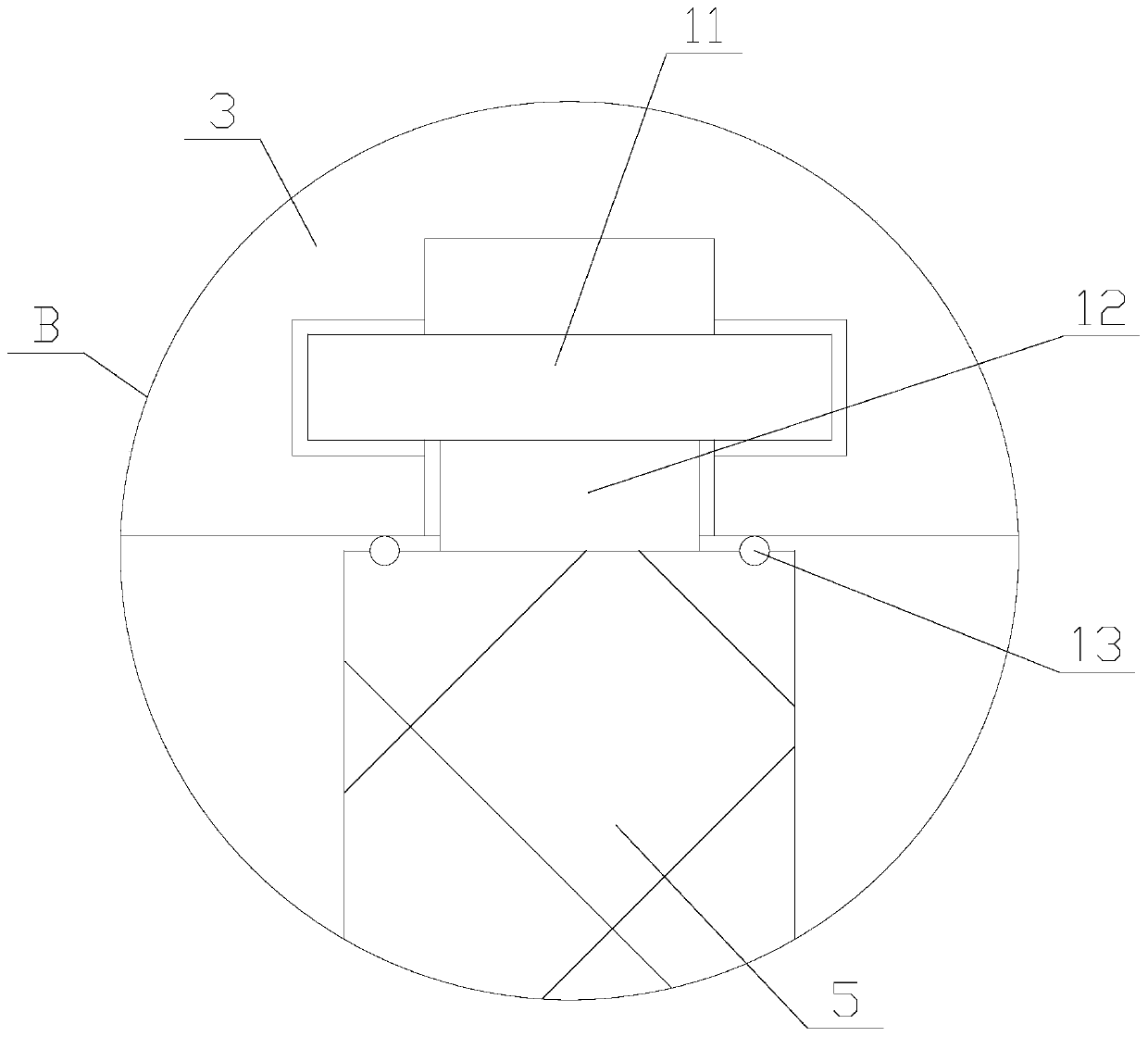

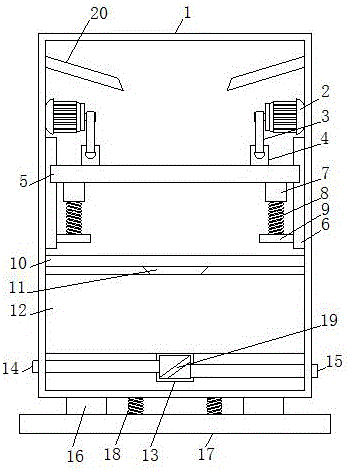

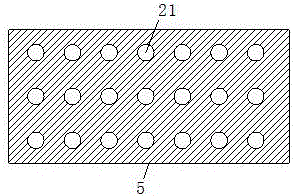

The invention discloses a grain thresher with the impurity removing function. The grain thresher comprises a base, a controller is fixedly installed on the front surface of the base, a bottom plate is fixedly installed at the bottom of the inner wall of the base, damping springs are fixedly installed at the top of the bottom plate, cushion blocks are fixedly installed at the tops of the damping springs, a baffle is fixedly installed at the tops of the cushion blocks, two supporting rods and a first motor are sequentially installed at the top of the baffle from left to right, and a belt pulley is fixedly installed on an output shaft of the first motor and provided with a belt. According to the grain thresher with the impurity removing function, as a vibrator, a screen and an impurity box are arranged, grain is fully separated before entering a separating box, impurities in the grain can be effectively removed and prevented from affecting product quality, the grain purity is effectively improved, and production income is increased.

Owner:XINING YIGE INTPROP CONSULTING SERVICE

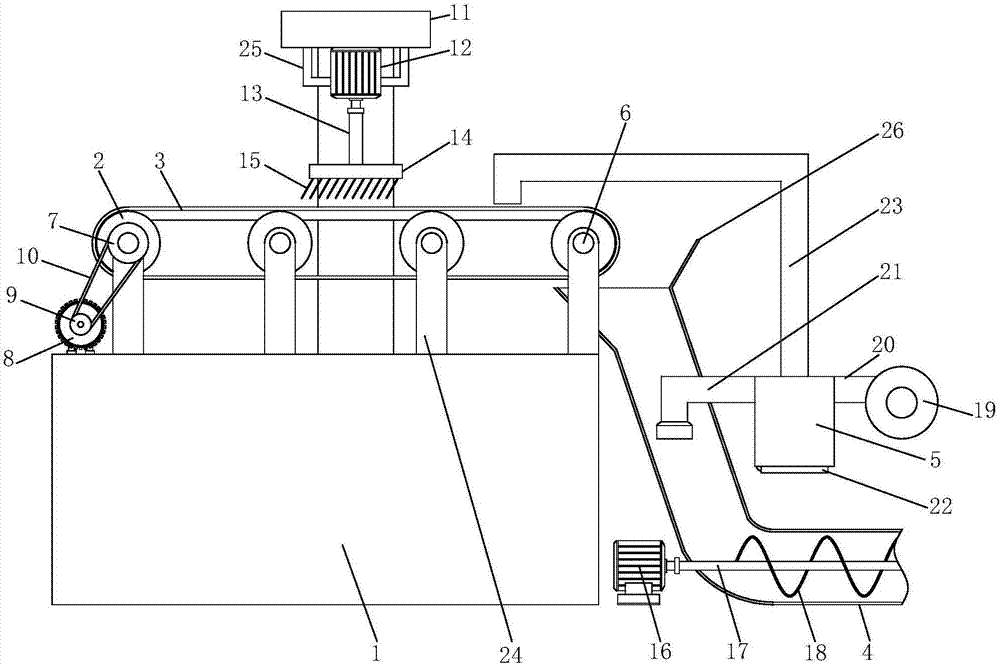

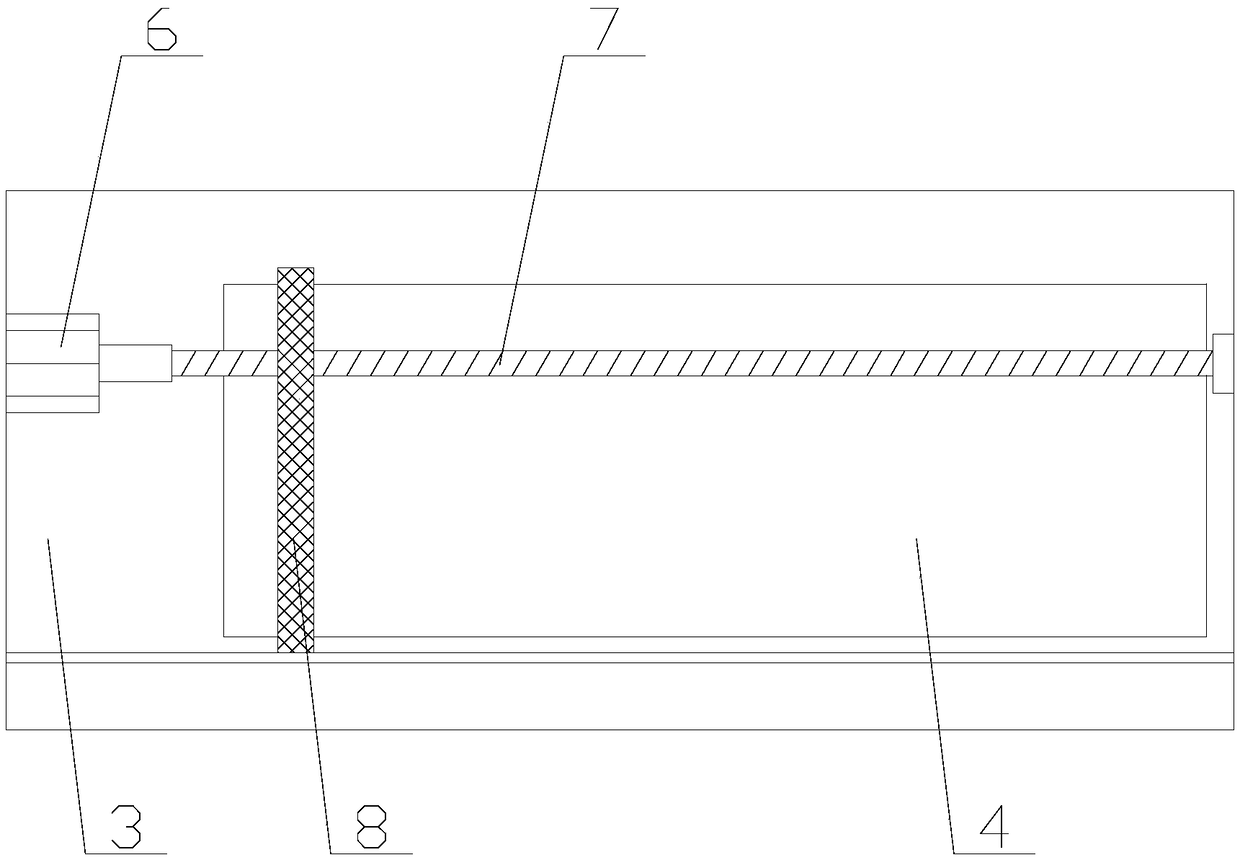

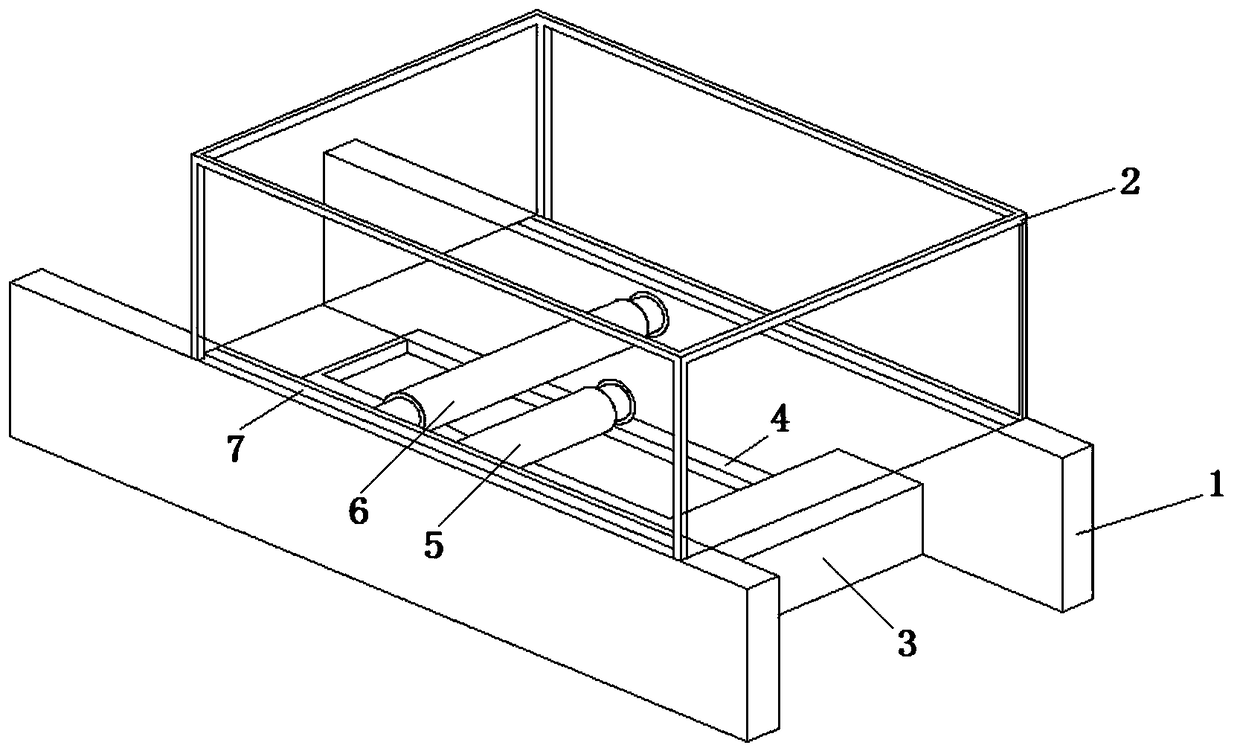

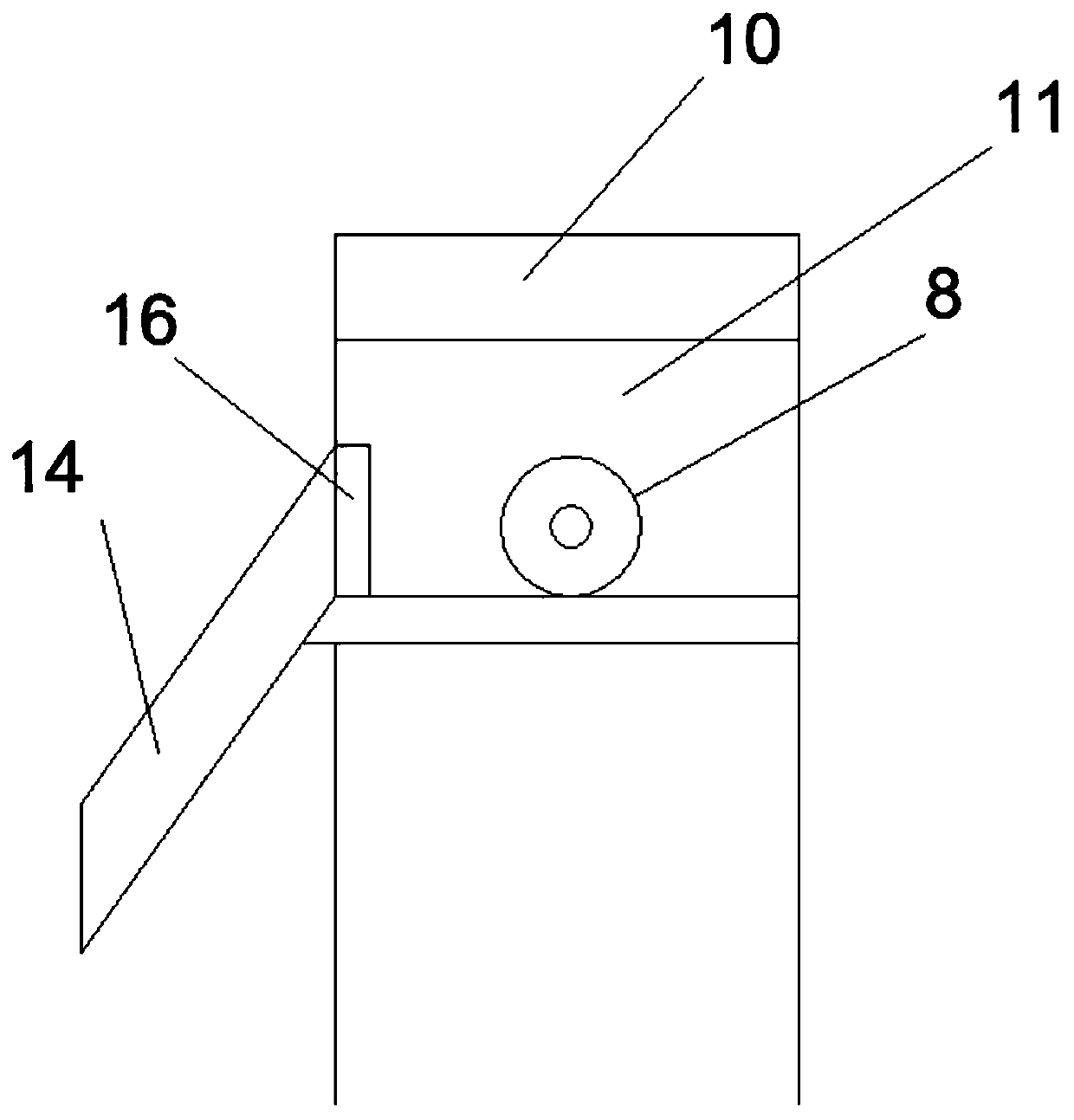

Metal part conveying machine with impurity-removing function

ActiveCN106890808AWith impurity removal functionImprove transport efficiencyGas current separationDirt cleaningDrive wheelElectric machinery

The invention discloses a metal part conveying machine with an impurity-removing function. The metal part conveying machine comprises a worktable, wherein four conveying rolls which are arranged at equal intervals are arranged on the top of the worktable; a conveyer belt is wound on the conveying rolls; a material conveying elbow is arranged on the right side of the worktable; an impurity-removing box is arranged on the right side of the material conveying elbow; the diameter of each conveying roll is gradually increased from a middle part to two ends; two ends of each conveying roll are separately provided with a mandrel; a driven wheel is arranged on the front surface of the mandrel on the left side of each conveying roll on the top of the worktable; and a driving motor is fixedly arranged on the left side of the top of the worktable. The metal part conveying machine has the advantages that metal parts can be conveniently conveyed by working personnel during production; structure is simple; operation is more convenient; impurities and dust on the outer surfaces of the metal parts can be effectively removed during conveying; working load of the working personnel is effectively lowered; and conveying efficiency of the metal parts is improved.

Owner:合肥迅达电器有限公司

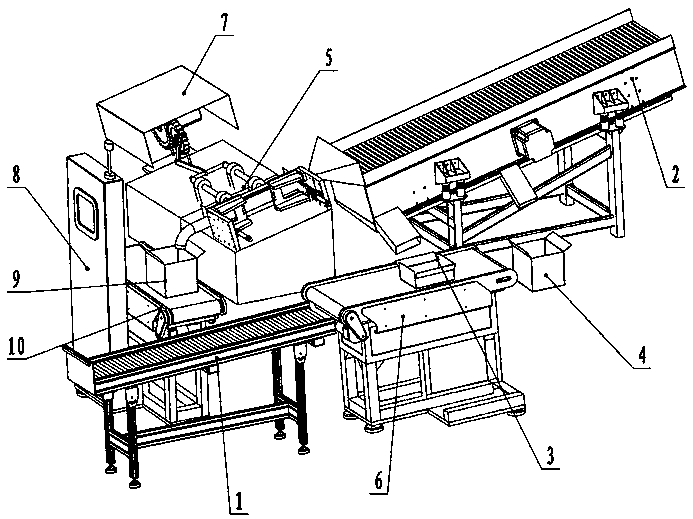

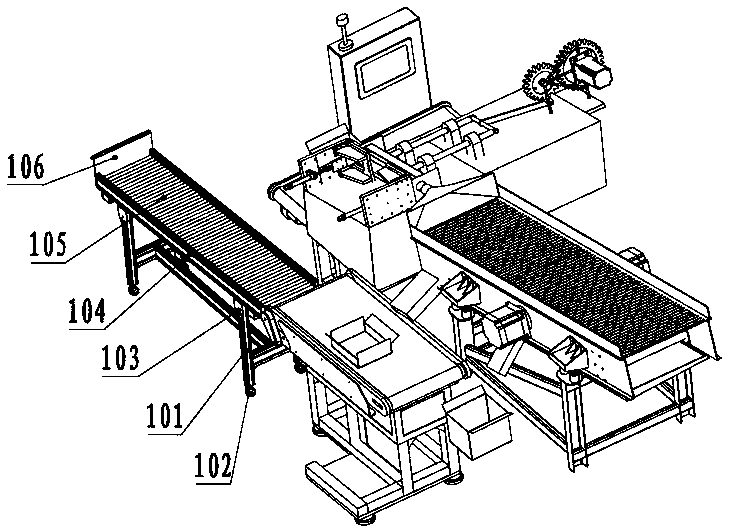

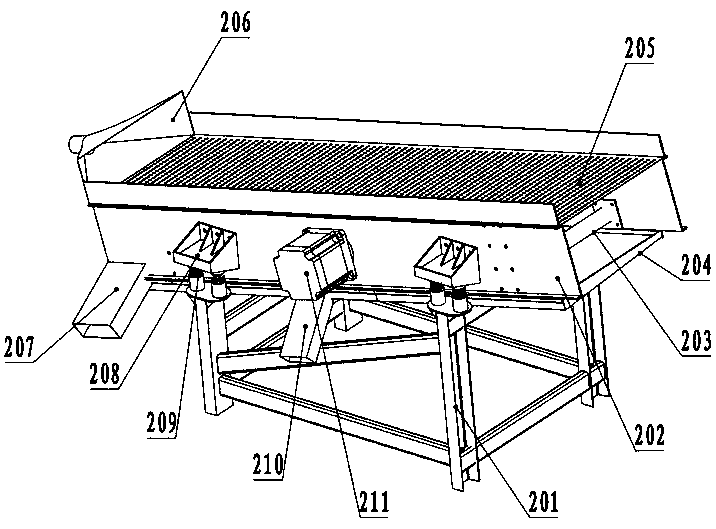

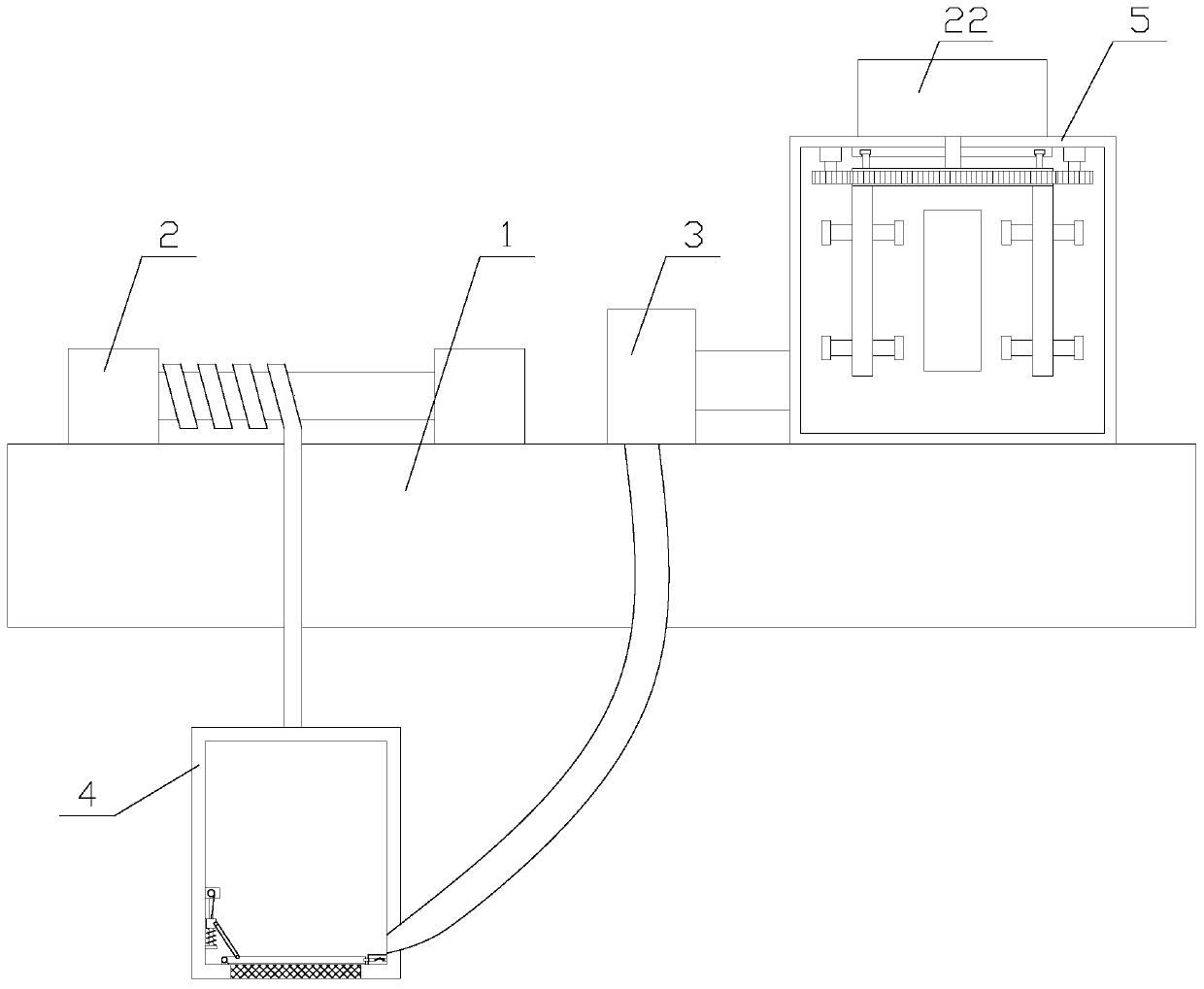

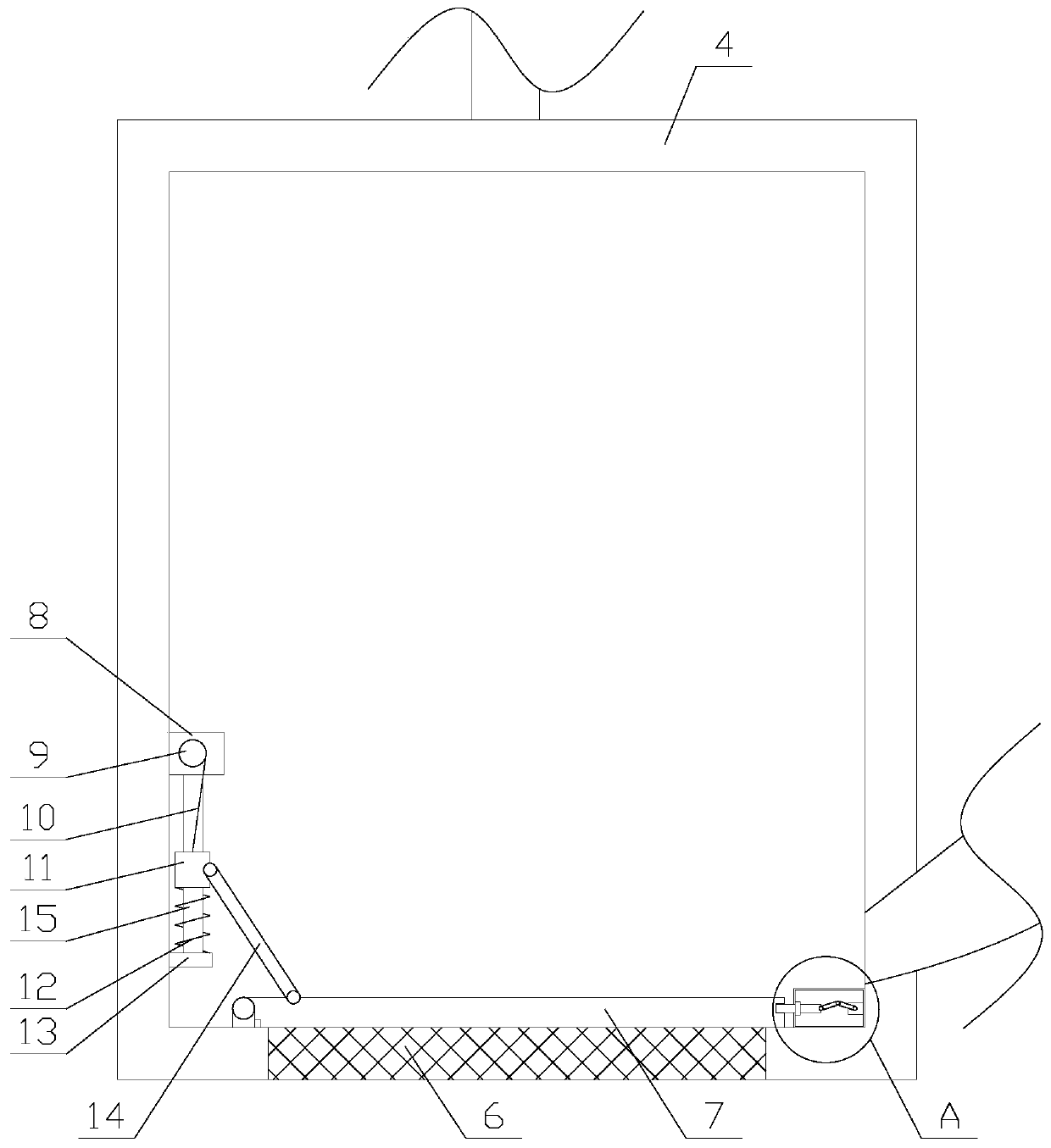

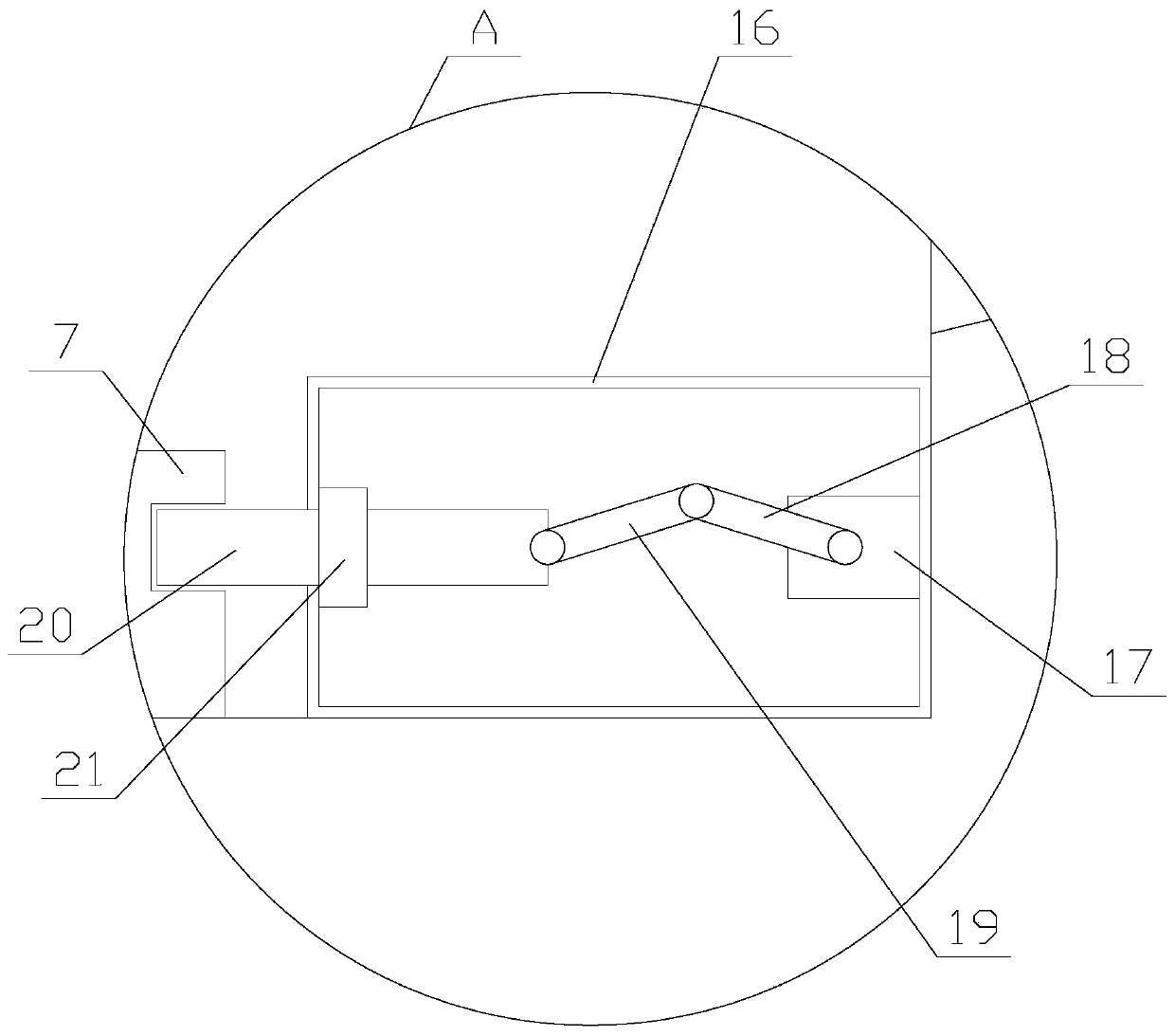

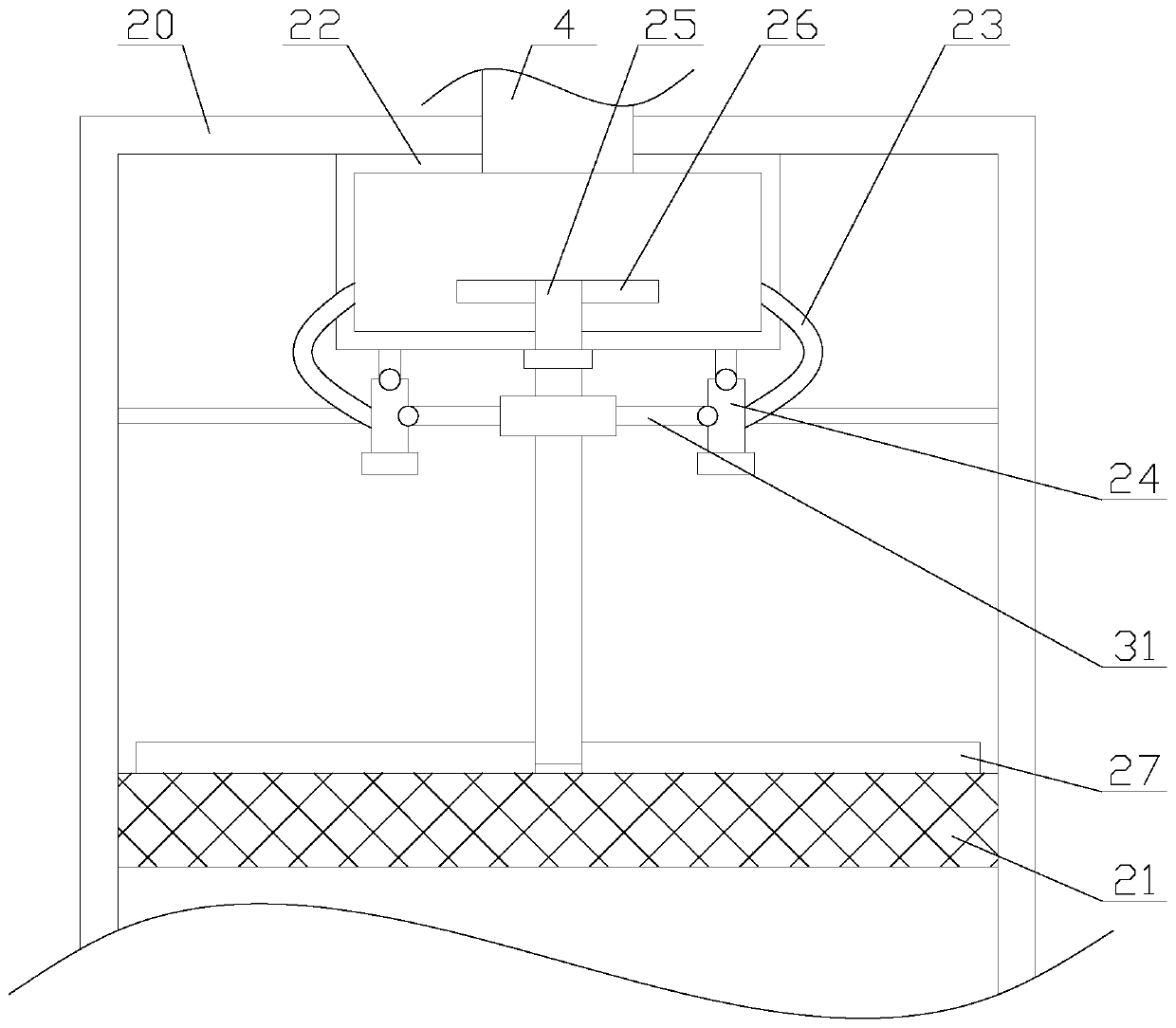

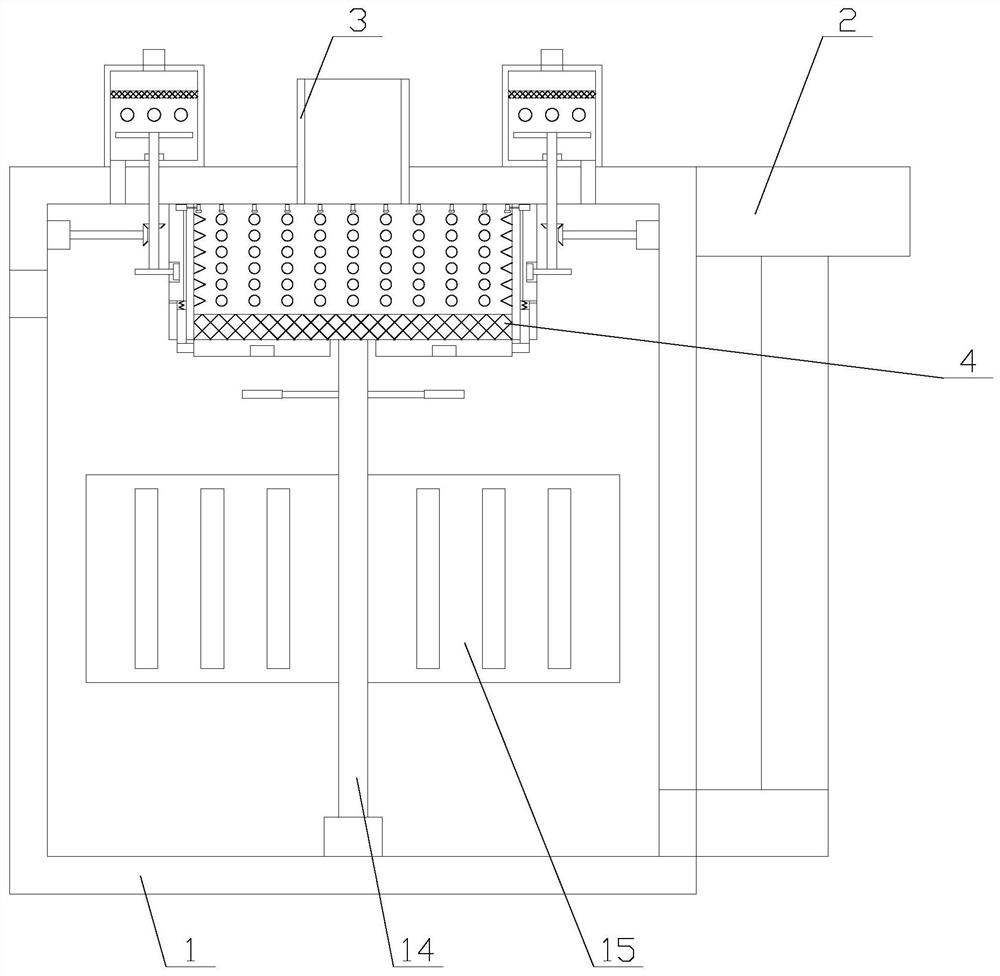

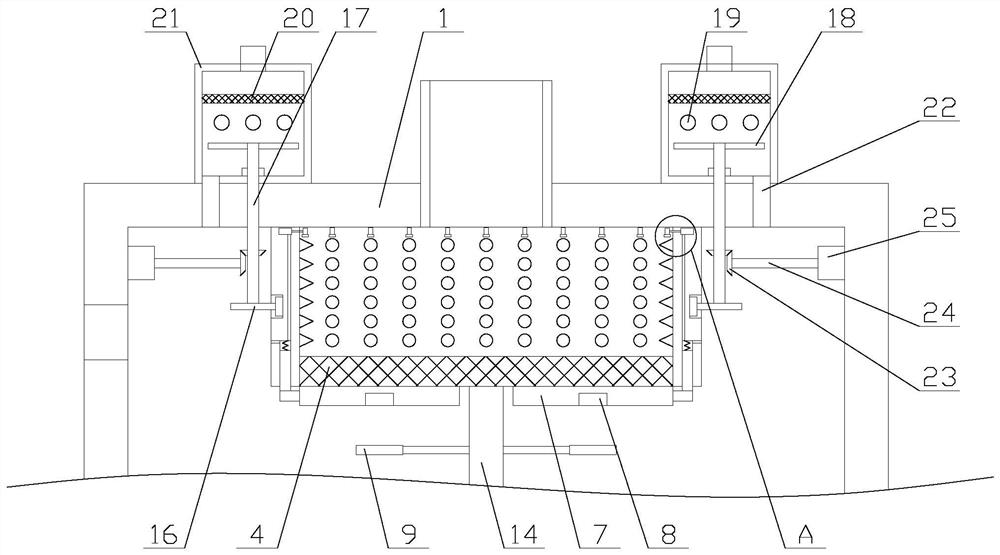

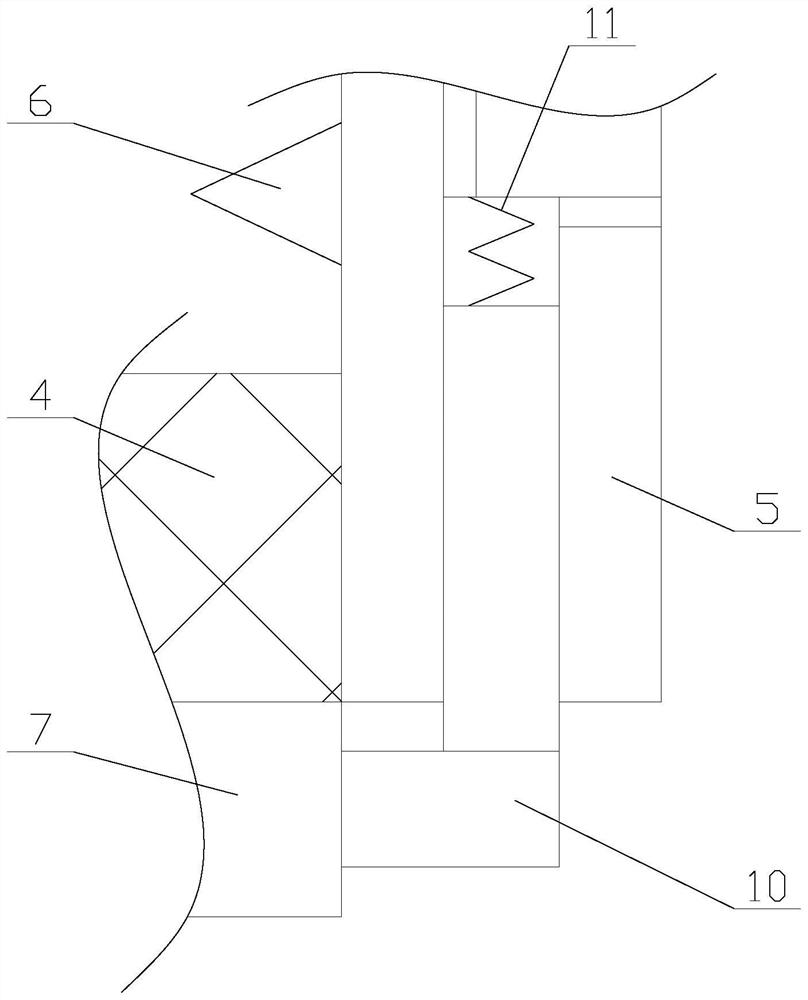

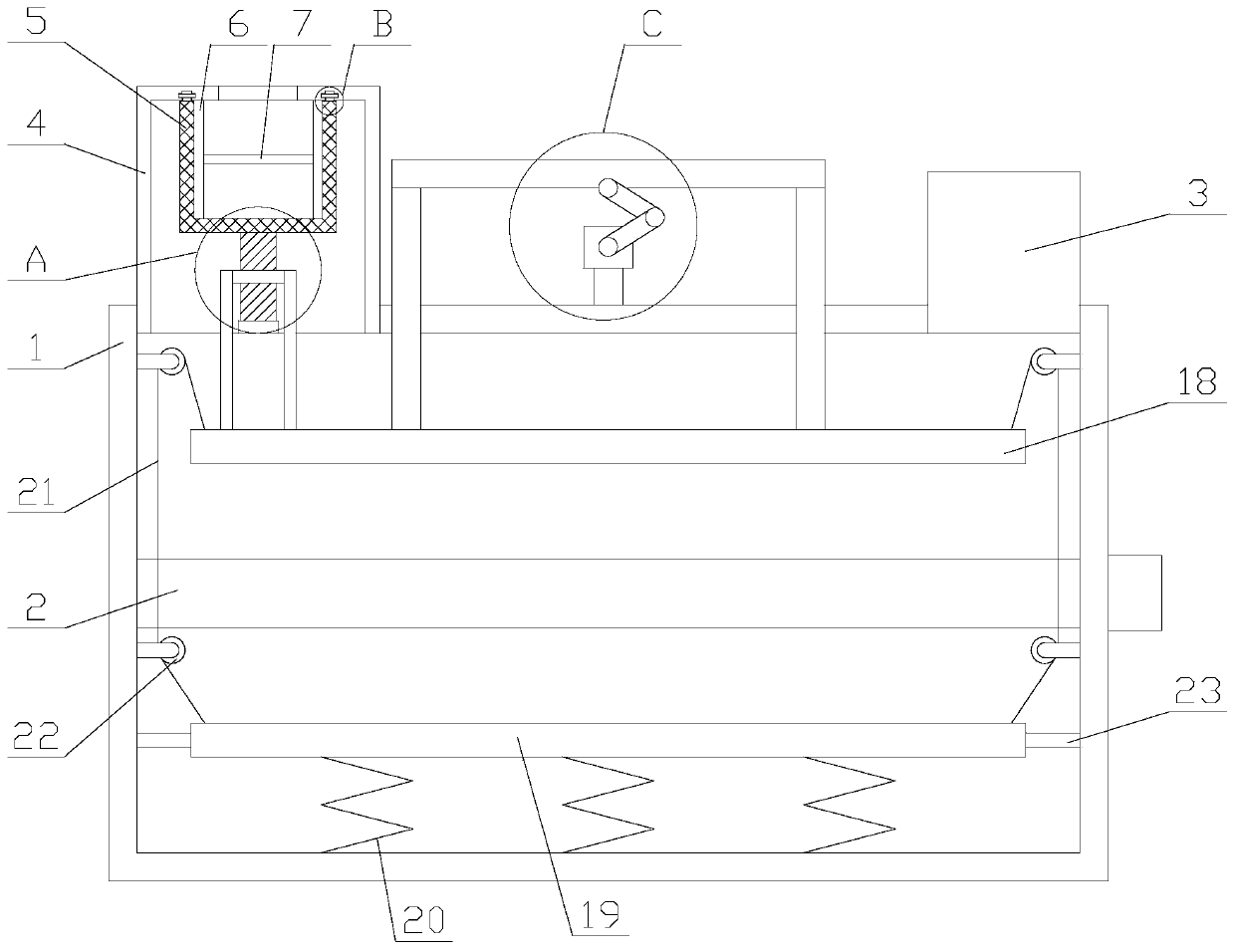

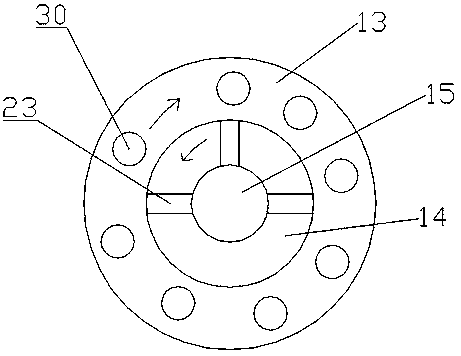

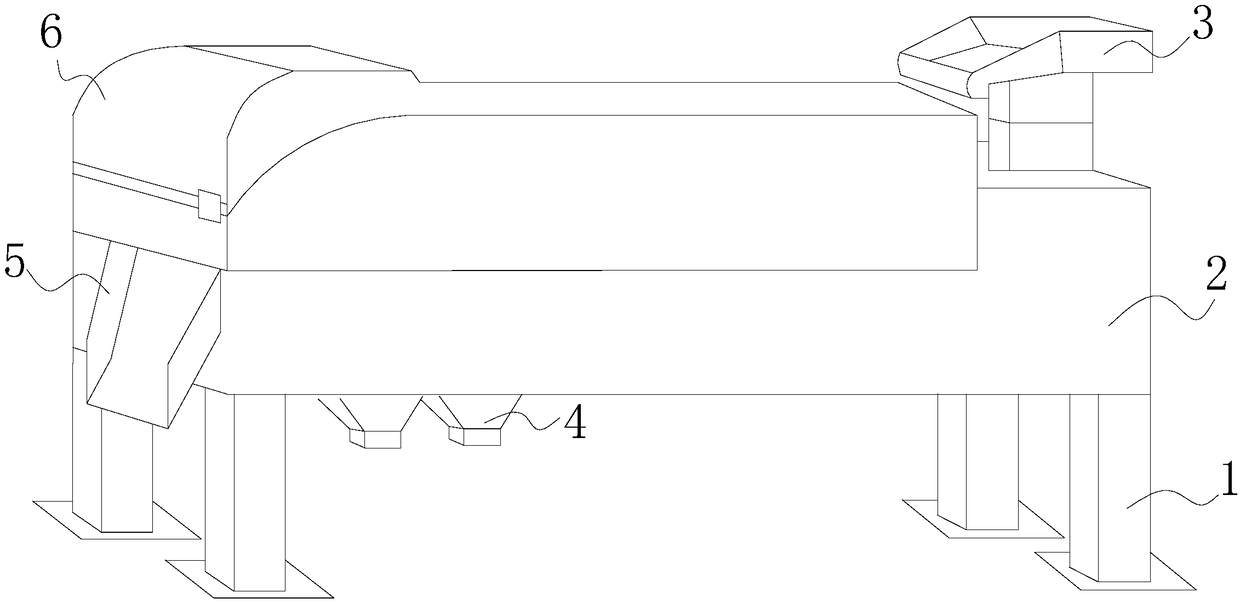

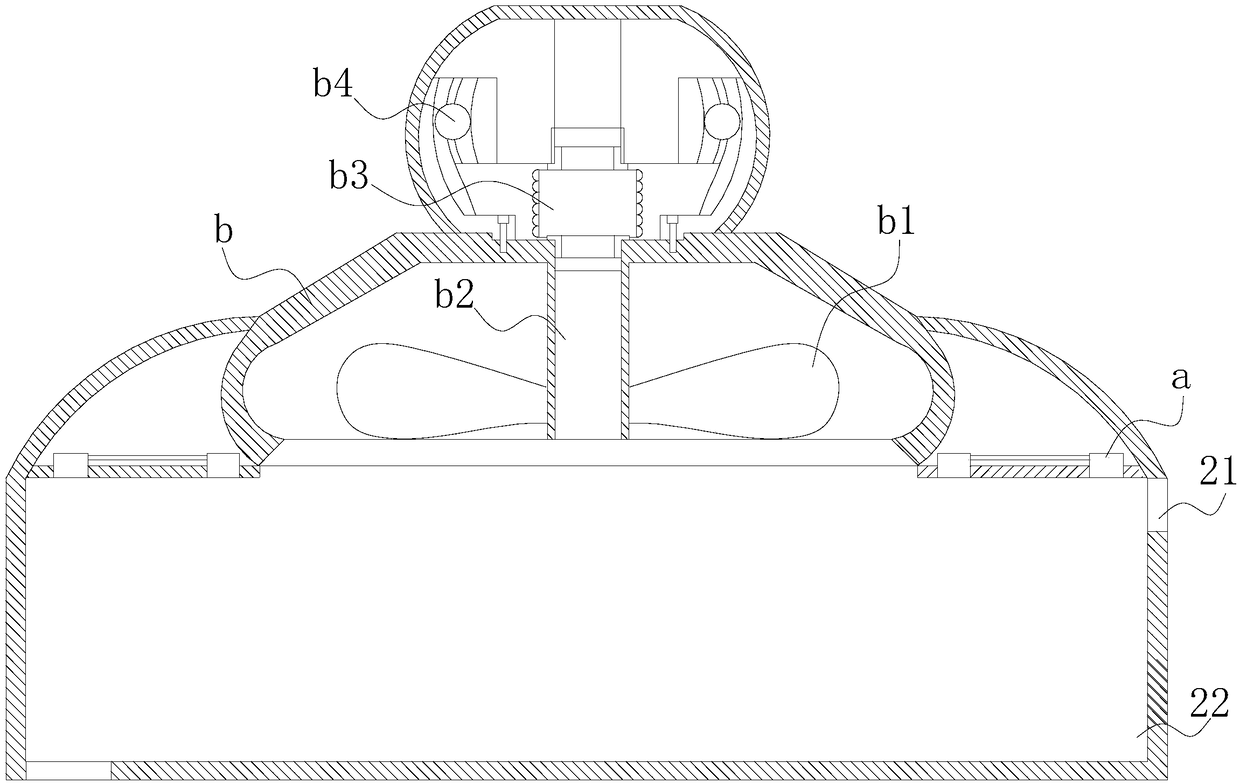

Agricultural product screening and weighing system

PendingCN111136005AImprove sorting efficiencyUniform particlesSievingScreeningAgricultural engineeringStructural engineering

The invention discloses an agricultural product screening and weighing system which comprises a sorting device, an opening device, weighing-conveying belts, a packaging box conveying roller bed, a protective cover and a console, wherein the sorting device mainly comprises a screening body; the screening body is composed of lateral plates, a bottom tray and a screening plate which are supported bya bracket; through the vibrating action of vibrating motors fixed on two sides of the screening body, hazelnuts are subjected to three-stage impurity removal and classification by utilizing the natural slope of the screening plate and by adopting the vibrating screening principle; defective hazelnuts obtained from the classification and screening process are boxed and collected through a first discharging port; second-stage non-defective products are loaded into packaging boxes through a second-stage discharging port; through a lateral non-defective product weighing-conveying belt, the second-stage non-defective products are conveyed to a discharging roller bed for quantitative packaging after being weighed; finally-sorted high-quality hazelnuts reach the opening mechanism through an end-part discharging hopper and are opened under the squeezing action of a motor connecting rod; finally, the high-quality hazelnuts are loaded into the packaging boxes; and through a lateral high-qualityproduct weighing-conveying belt, the high-quality hazelnuts are conveyed to the discharging roller bed for quantitative packaging after being weighed. The integrated flow operation of impurity removal, screening, opening, weighing and packaging is achieved.

Owner:董昊

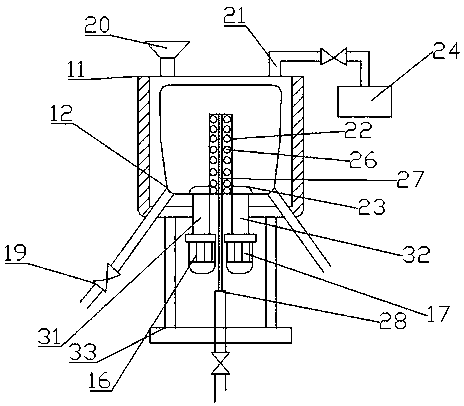

High-reliability water quality monitoring equipment having impurity removal function

InactiveCN109975503AWith impurity removal functionImprove cleanlinessPreparing sample for investigationTesting waterWater qualityEngineering

The invention relates to high-reliability water quality monitoring equipment having an impurity removal function. The equipment includes a main body, an elevating device, a sampling chamber, a water pumping device, a detecting chamber, a detecting device, an impurity removal mechanism and a cleaning mechanism; the impurity removal mechanism includes a filter screen, an enclosed plate, a supportingshaft, a driving assembly and a fixing assembly; the driving assembly includes a first motor, a wire reel, a stay wire, a slide block, a fixing plate, an adjusting rod and a spring; the cleaning mechanism includes a clear water tank, a communicating pipe, a rotary box, two power assemblies and two cleaning assemblies; and the cleaning assemblies includes a connecting pipe and multiple nozzles. Through the cleaning mechanism, cleaning work can be performed on the inner wall of the detecting chamber and the detecting device, so that impurities can be prevented from covering on the detecting device to affect the detection effects of next sampling water, and therefore, the reliability of the equipment can be enhanced; and through the impurity removal mechanism, creatures in the water can be prevented from entering the detecting chamber to affect the detection effects.

Owner:蒋宗霞

Urban rainwater filtering mechanism with impurity removing function

InactiveCN109107265AWith impurity removal functionNo pollutionTreatment involving filtrationRunoff/storm water treatmentSand filterWater pipe

The invention discloses an urban rainwater filtering mechanism with impurity removing function. The urban rainwater filtering mechanism comprises a shell, wherein the bottom portion of the shell is fixedly provided with a base, the top portion of the shell is fixedly connected to a water inlet pipe, the bottom portion of the water inlet pipe extends into the shell, the middle portion of one side of the shell is fixedly provided with a material receiving bucket, one side of the top portion of the material receiving bucket is fixedly connected to a pair of support legs, a fixing shaft is fixedlyconnected between the support legs, the upper portion of the inner cavity of the shell is provided with a filtering mechanism, and the middle portion of the inner cavity of the shell is fixedly connected to a connecting plate. According to the present invention, by arranging the filtering mechanism, the fine sand filtering box, the filtering cylinder and the precision filtering screen, dead twigs, leaves, artificial garbage and other impurities in rainwater can be discharged into urban river after multiple filtrations, such that the rainwater discharged in the urban river cannot cause environment pollution so as to achieve the good living environment.

Owner:湖州益创环境工程有限公司

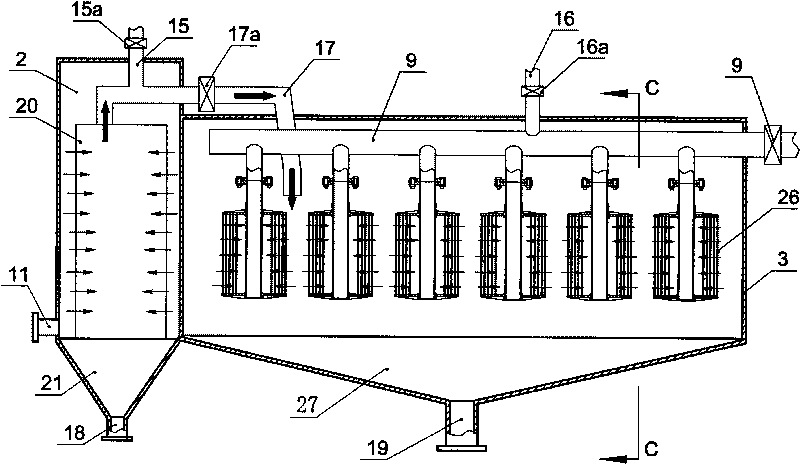

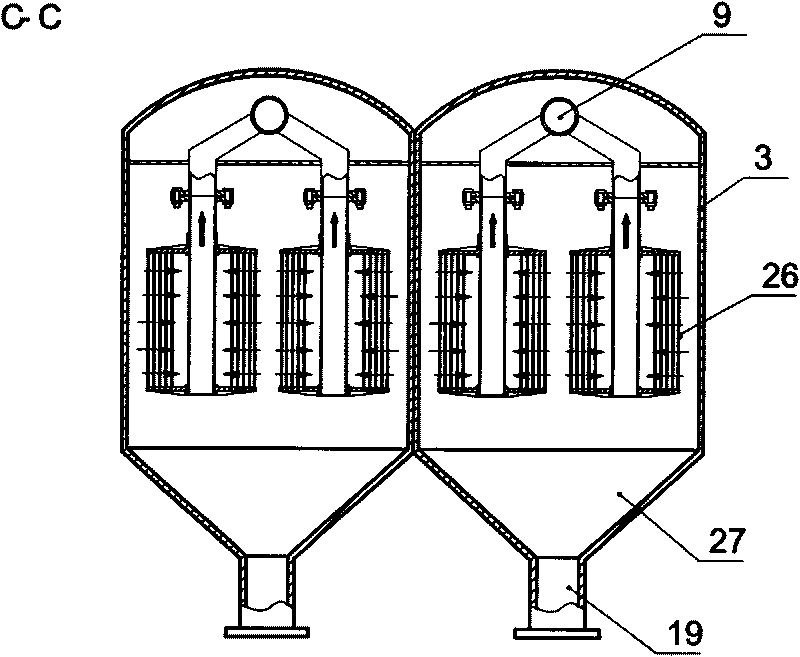

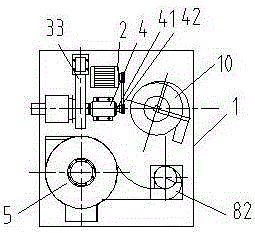

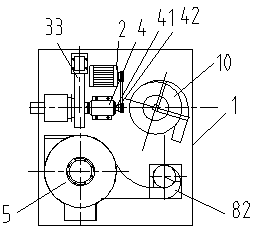

Oil filter of nonferrous metal foil rolling industry

InactiveCN101690954AReduce capital investmentReduce economic lossWork treatment devicesFiltration circuitsPipingEngineering

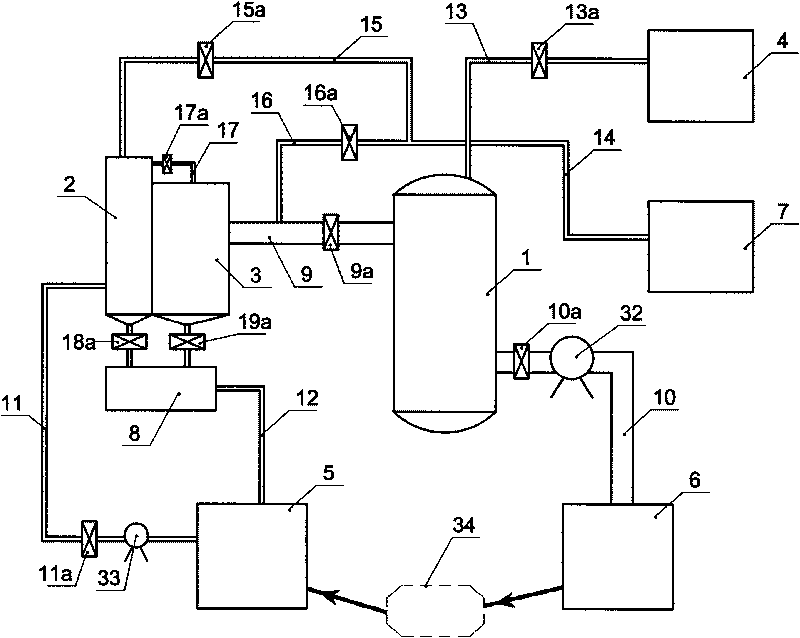

The invention relates to an oil filter of nonferrous metal foil rolling industry, comprising a sump oil pool or a sump oil tank, an oil cleaning pool or an oil cleaning tank, and an oil filtering system, wherein the oil filtering system comprises a coarse filtering oil-water separation device, a fine filtering destaining device, a buffering tank and a vacuum pump; the oil outlet of the coarse filtering oil-water separation device is communicated with the fine filtering destaining device through a pipeline, the oil inlet of the coarse filtering oil-water separation device is communicated with the sump oil pool or the sump oil tank by the pipeline or a piping pump, the oil outlet of the fine filtering destaining device is communicated with the upper part of the buffering tank by a pipeline, the oil cleaning pool or the oil cleaning tank is communicated with the lower part of the buffering tank, and the vacuum pump is communicated with the top part of the buffering tank by a pipeline. The oil filter of the invention can realize on-line cycle operation, does not need to add filter aid duty to duty, and does not need to change filter cloth day to day, thereby not only saving a great amount of funding, but also avoiding economic loss caused by machine halt. The oil filter has no effluent discharge, high automation degree, easy control, simple structure and convenient operation, reduces labor intensity for workers, and is beneficial to environment protection and promotion and implementation.

Owner:焦保安

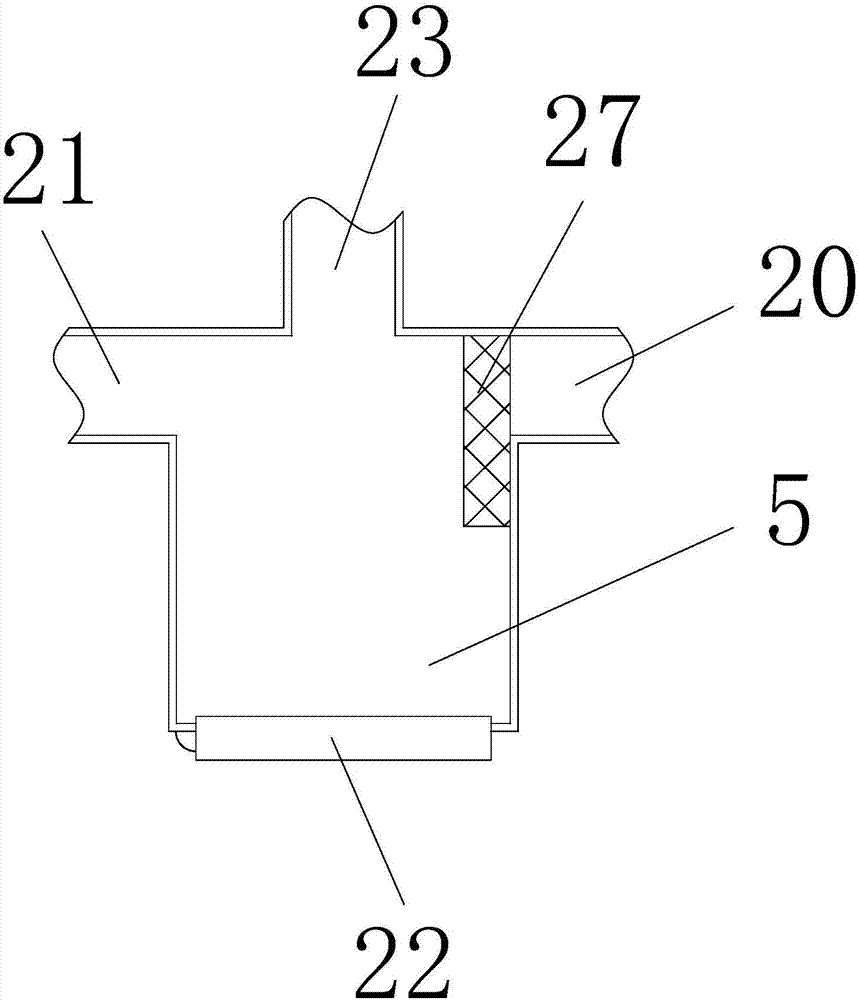

Sesame seed stir-frying device with preheating

The invention discloses a sesame frying device with preheating, which includes a preheating drying device and a roasting device. The preheating drying device includes a drying barrel, a collection chamber and an impurity chamber. The drying barrel includes a fixedly connected drying chamber and a drying chamber. Drying cone, the drying cone is located at the lower part of the drying chamber; the roasting device includes a frying device and a cooling drum, the frying device includes a drum, the cooling drum is arranged at the outlet end of the drum, and the cooling drum passes through the intermediate piece and the drum Connected, the cooling cylinder is provided with a cooling outlet. The sesame frying device with preheating of the present invention has wide applicability, preheating and drying can greatly improve the efficiency of sesame frying, the frying device ensures that the sesame is evenly fried, and the frying situation can be monitored at any time during the frying process, At the same time, the excess high temperature during the frying process can be used to fry the sesame seeds at a low temperature. The fried sesame seeds can be cooled in time, and the entire processing process can also ensure continuity.

Owner:黄林海

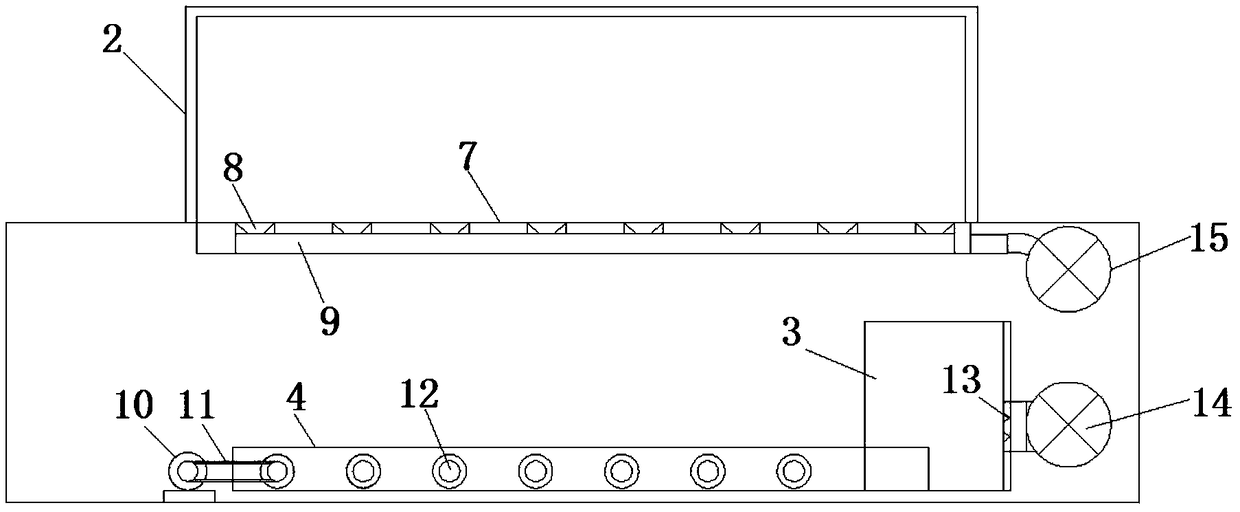

Multifunctional cereal drying equipment

InactiveCN107356052AImprove qualityEvenly heatedDrying solid materials with heatDrying gas arrangementsEngineeringMultiple function

The invention discloses multifunctional cereal drying equipment. The multifunctional cereal drying equipment comprises a drying box, a first air blower, a second air blower and a heating device, wherein the drying box is internally provided with a preheating bin and a drying bin, and strip-shaped channels are formed between the preheating bin and the drying bin; a first vibrating bed and a second vibrating bed are arranged in the drying bin, a plurality of through holes are distributed in the bed surface of the first vibrating bed, and a plurality of through holes are distributed in the bed surface of the second vibrating bed; a first air inlet, a second air inlet and a discharging port are formed in the drying bin, the first air inlet is located between the first vibrating bed and the second vibrating bed, the second air inlet is located below the second vibrating bed, and the discharging port is located above the second vibrating bed; an air outlet of the first air blower is connected with the first air inlet, and an air outlet of the second air blower is connected with the second air inlet; and the heating device is connected with the drying bin and is used for providing heat energy to the drying bin. According to the multifunctional cereal drying equipment, the drying speed is high, the uniformity is good, and grains are prevented from being burnt, cracked and broken effectively; and the multifunctional cereal drying equipment has an impurity removal function.

Owner:望江县乡缘农业有限责任公司

High-performance opener with cleaning function

InactiveCN110344140AWide range of sprayingReduce frictionFibre cleaning/opening machinesTextile treatment by spraying/projectingWater storageStationary case

The invention relates to a high-performance opener with a cleaning function, comprising a transfer box, a fixing block, a body, a fixing box, a cotton storage box and a base, as well as a water spraying mechanism and a cleaning mechanism. The water spraying mechanism comprises a water storage box, a driving assembly, a support plate, two nozzles and two hoses; the cleaning mechanism comprises a waste box and two vibrating assemblies; each vibrating assembly comprises a first motor, a turnplate, a rotating bar and a vibrating bar. The high-performance opener with the cleaning function has the advantages that cotton is wetted through the water spraying mechanism so that friction of the cotton is lessened, tearing apart the cotton is convenient, and cotton loosening efficiency is improved; the loosened cotton can be cleaned through the cleaning mechanism, so that cotton opening quality is improved.

Owner:JIAXING UNIV

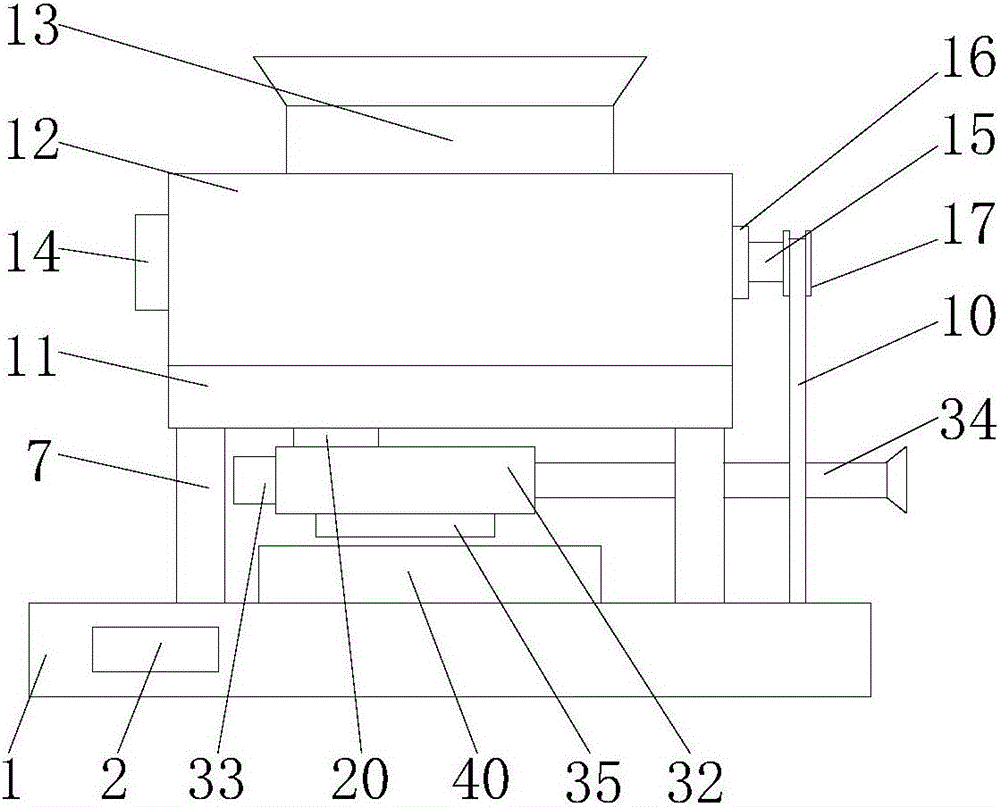

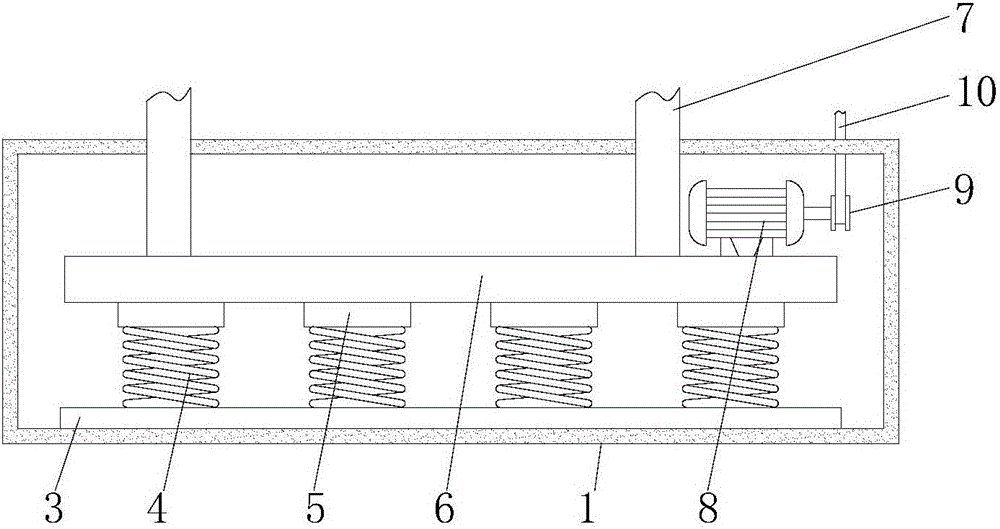

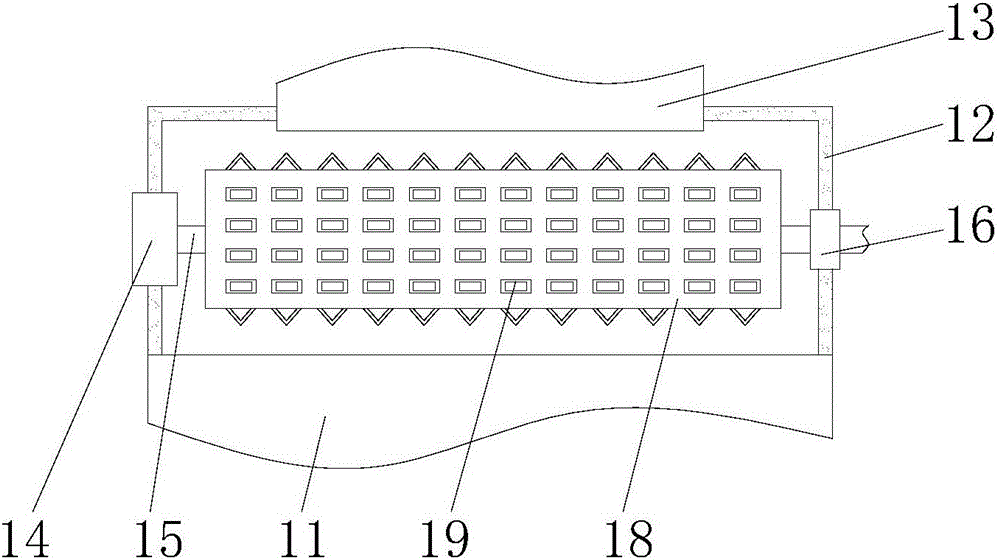

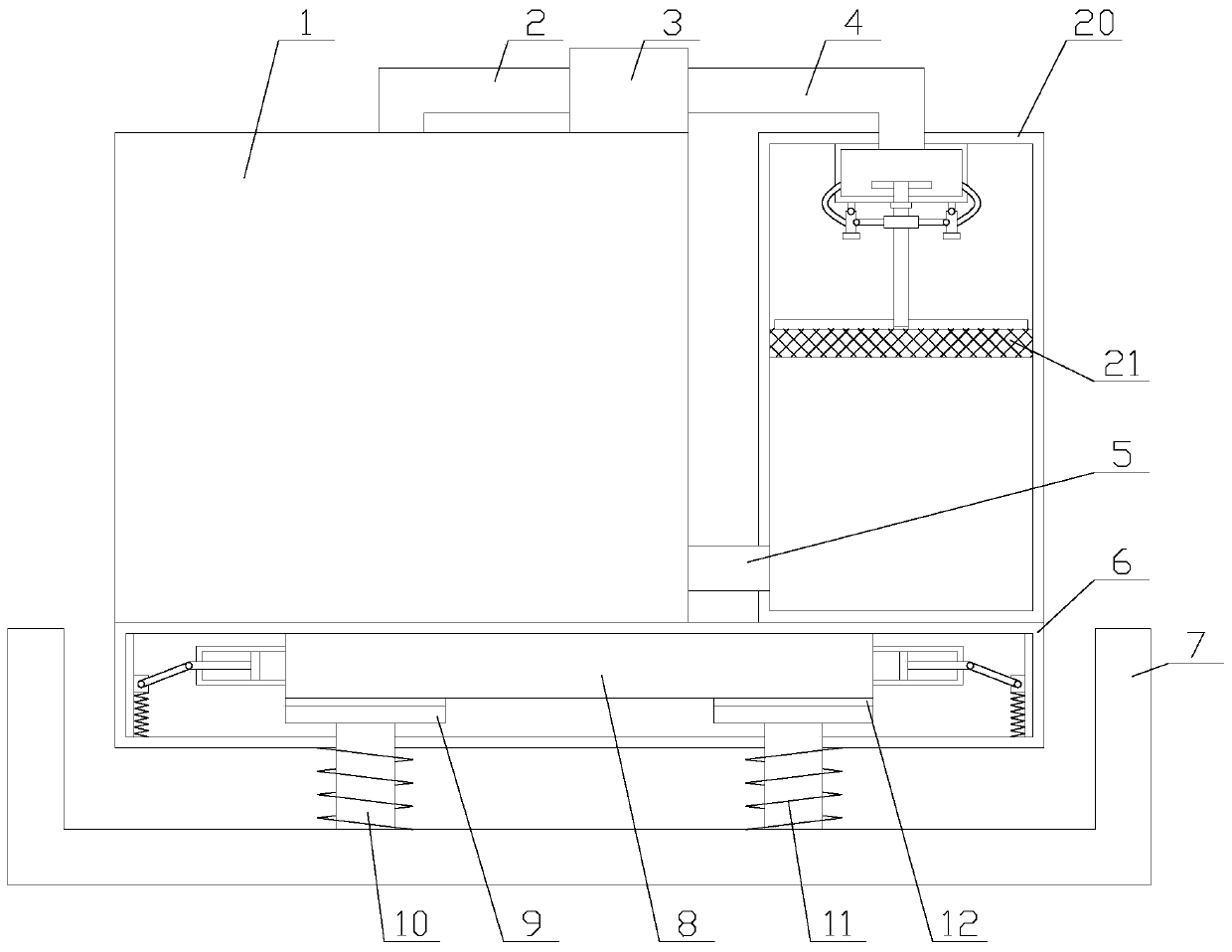

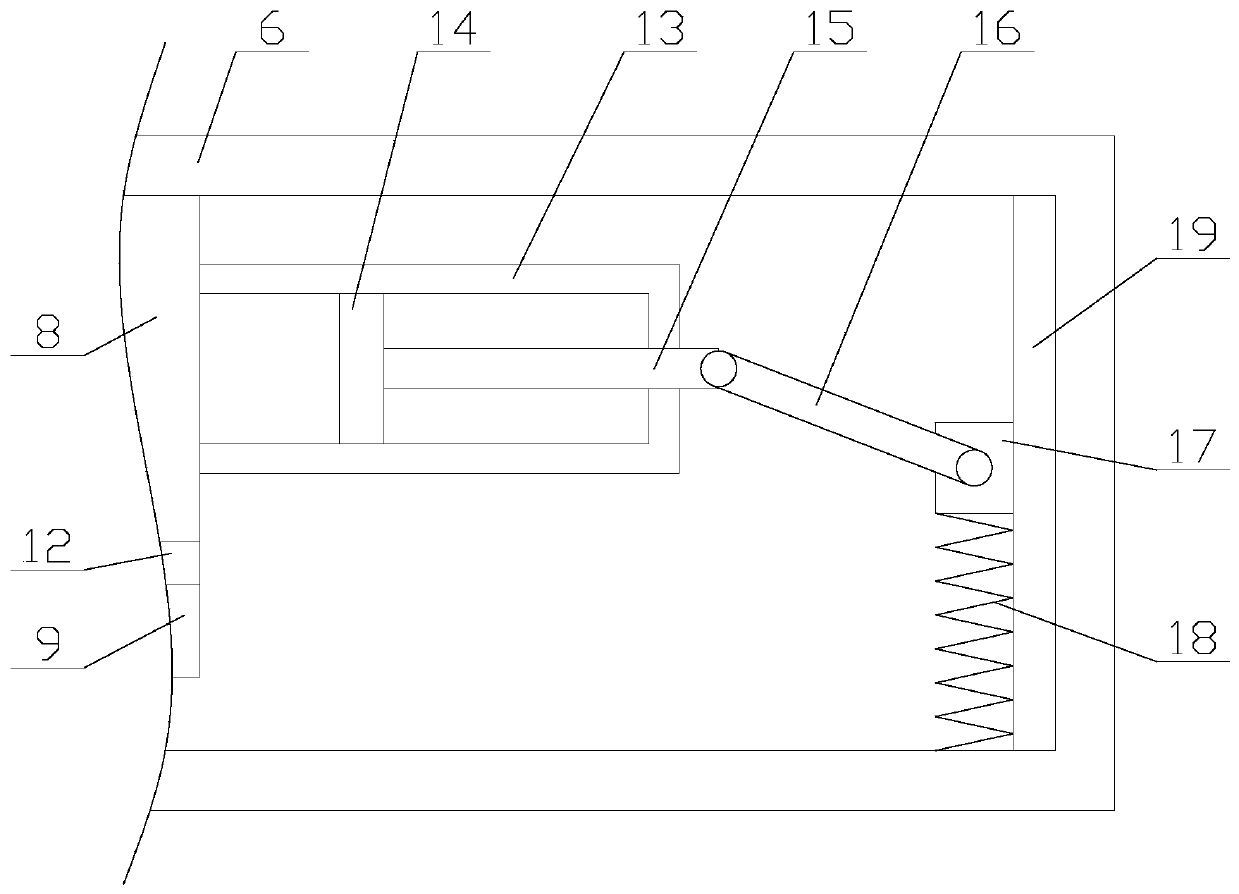

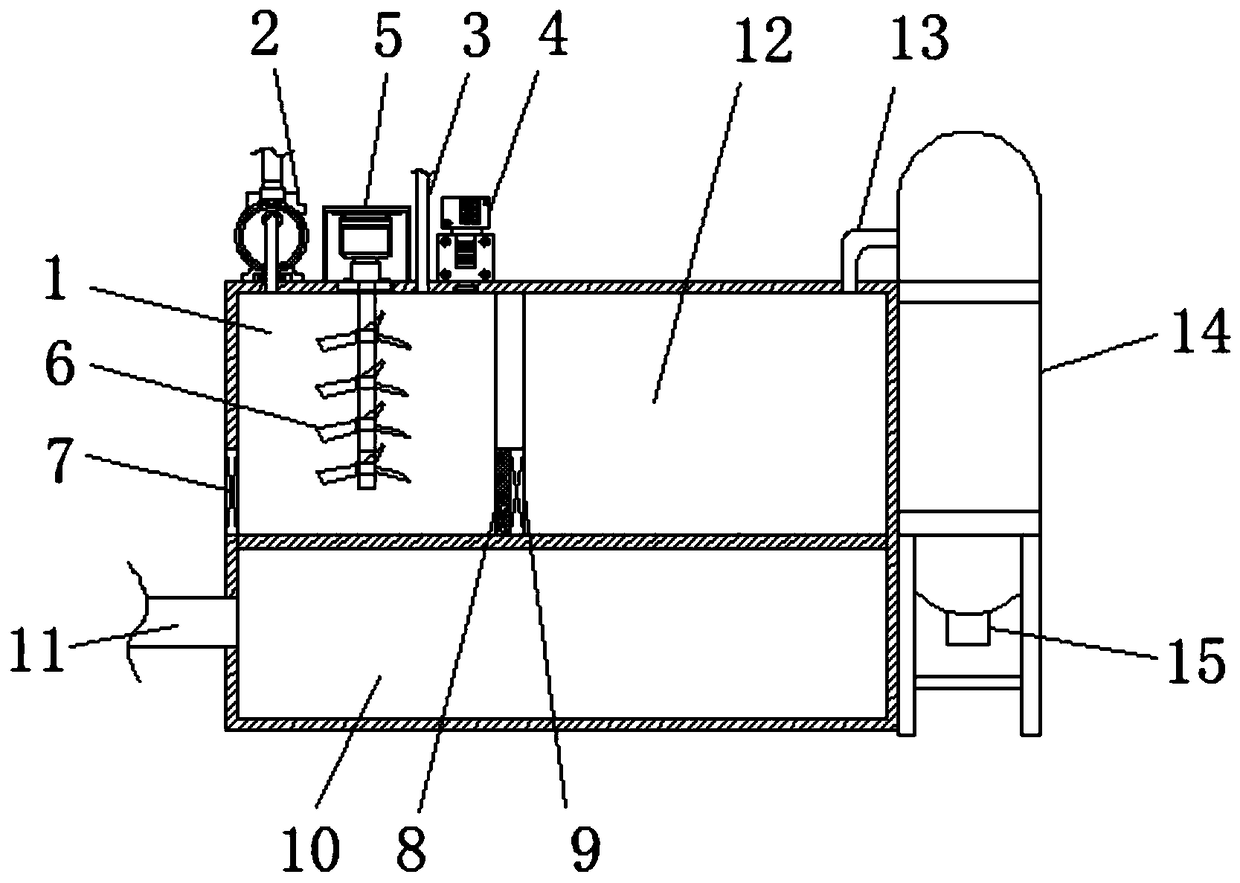

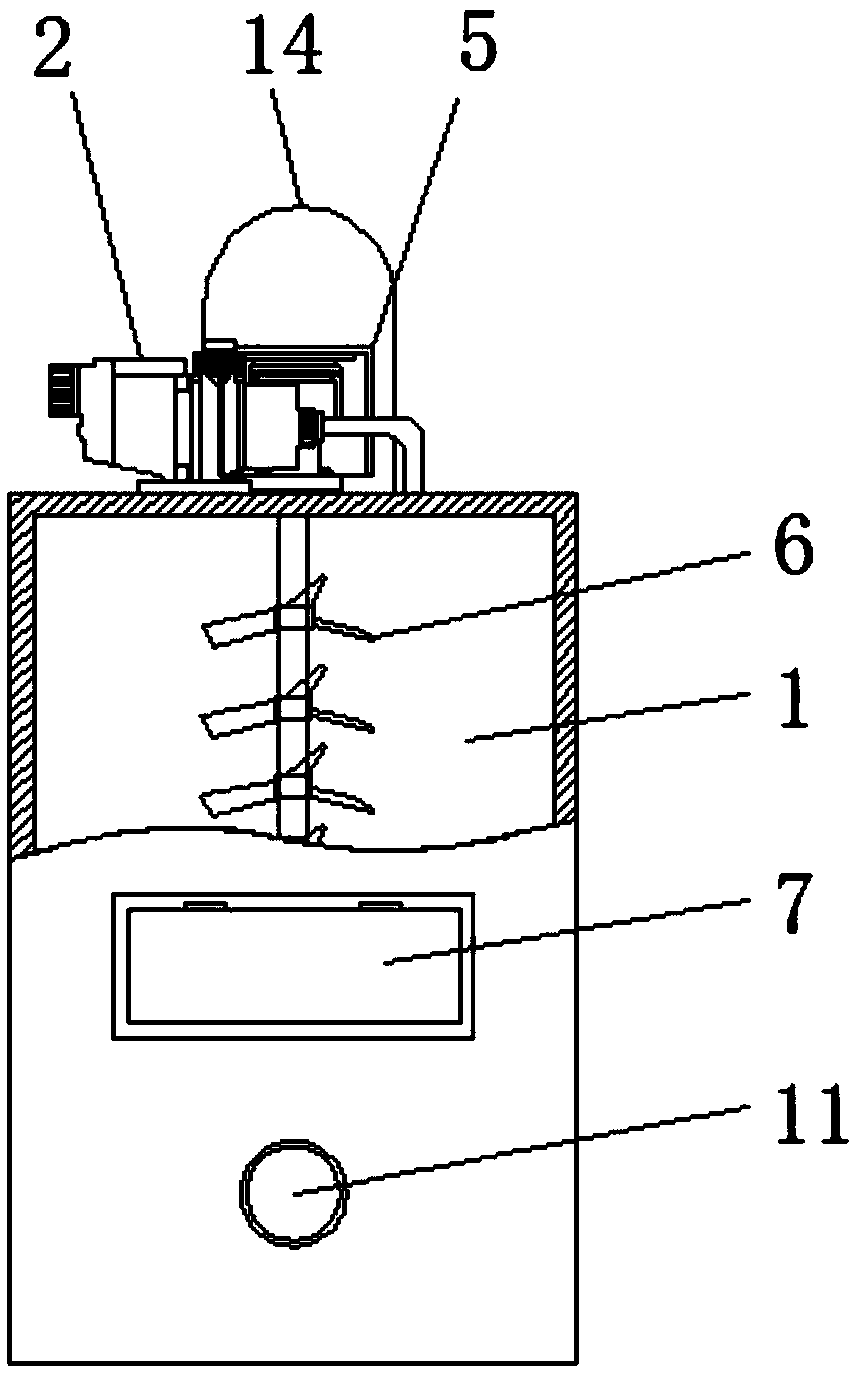

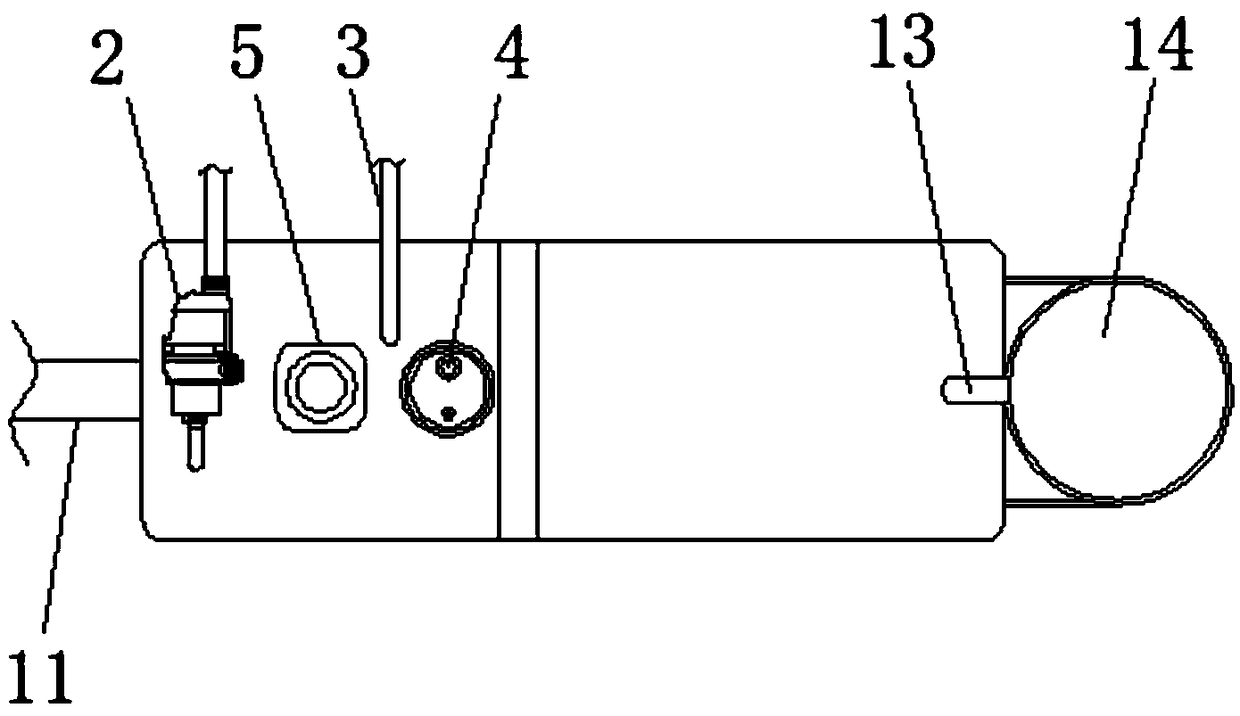

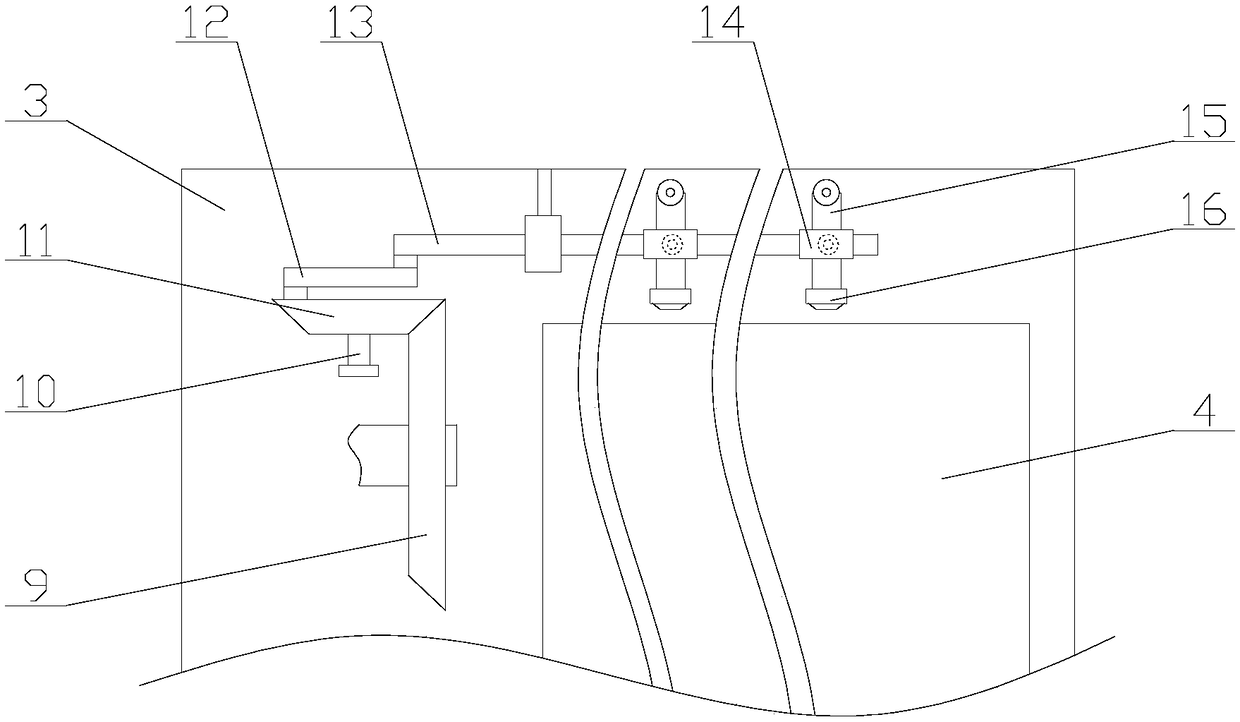

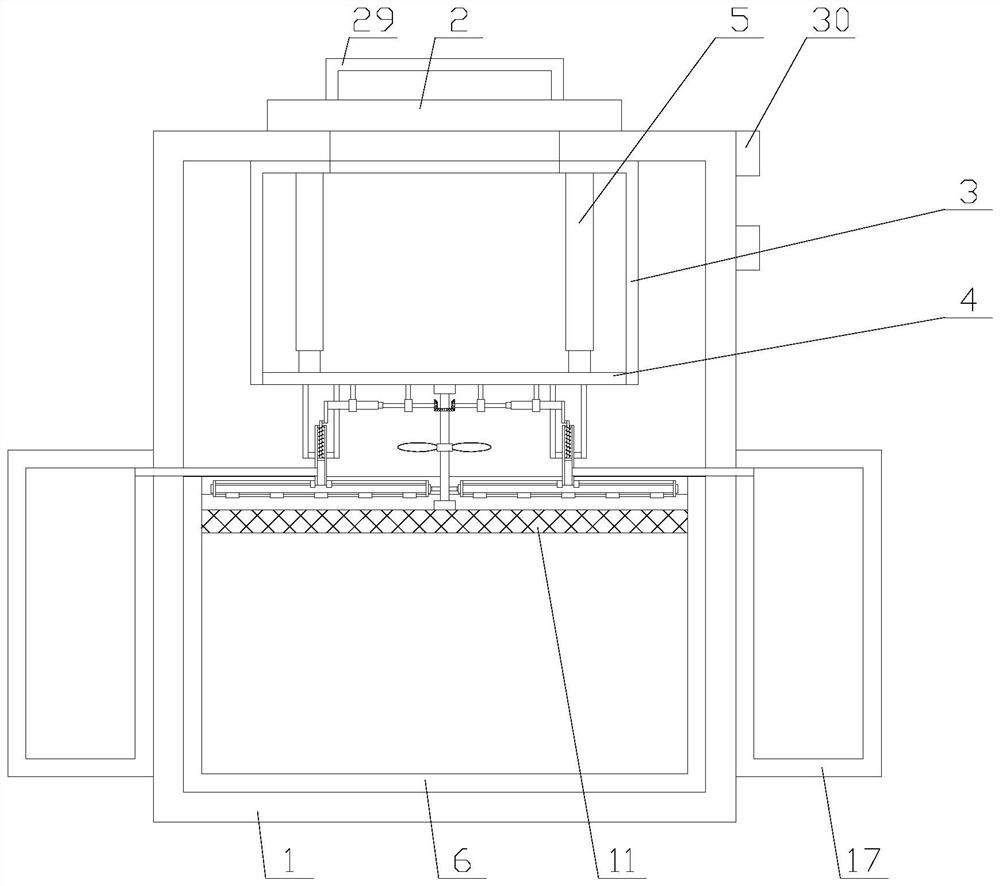

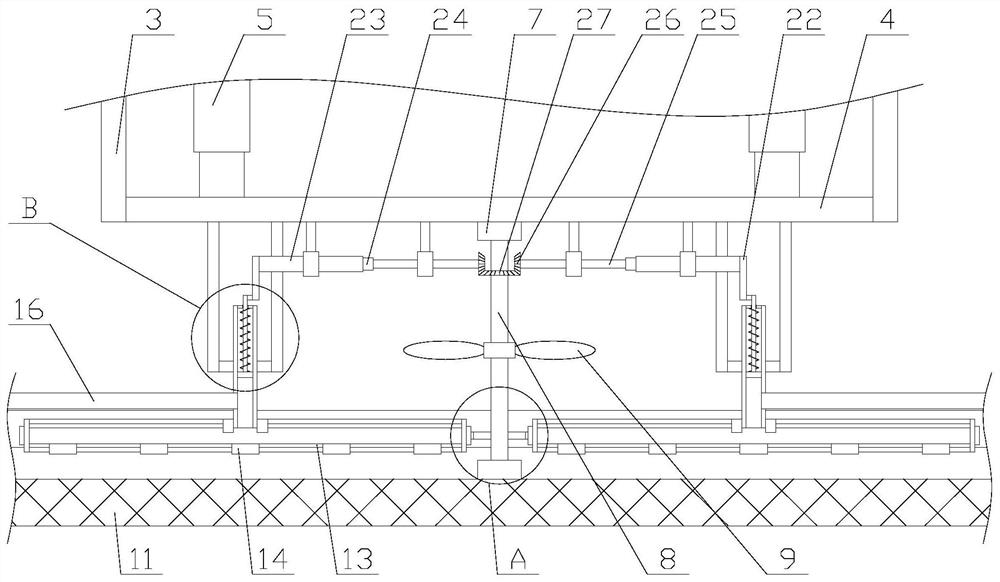

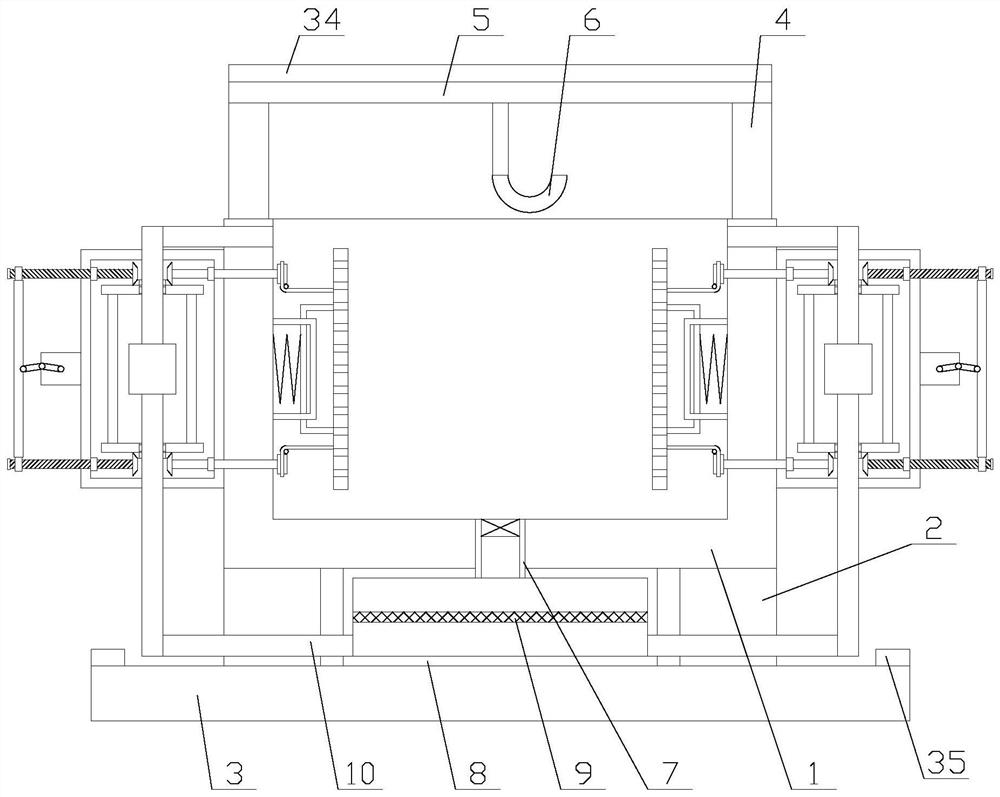

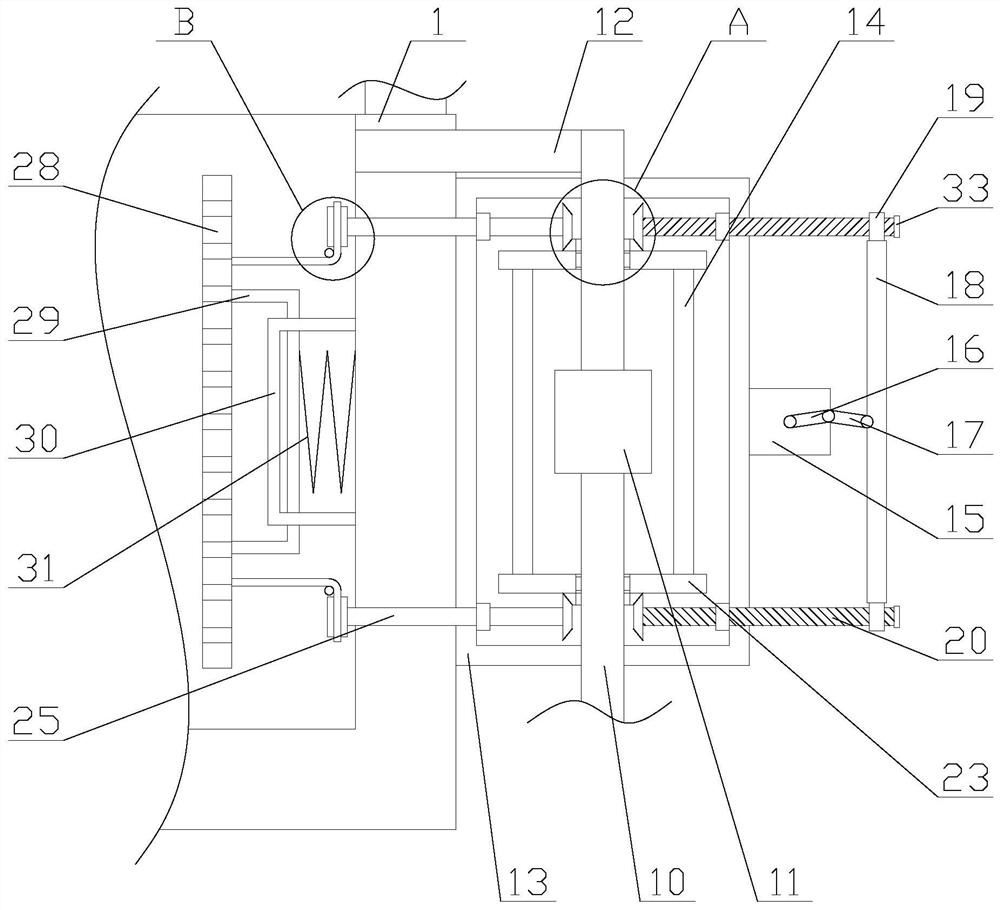

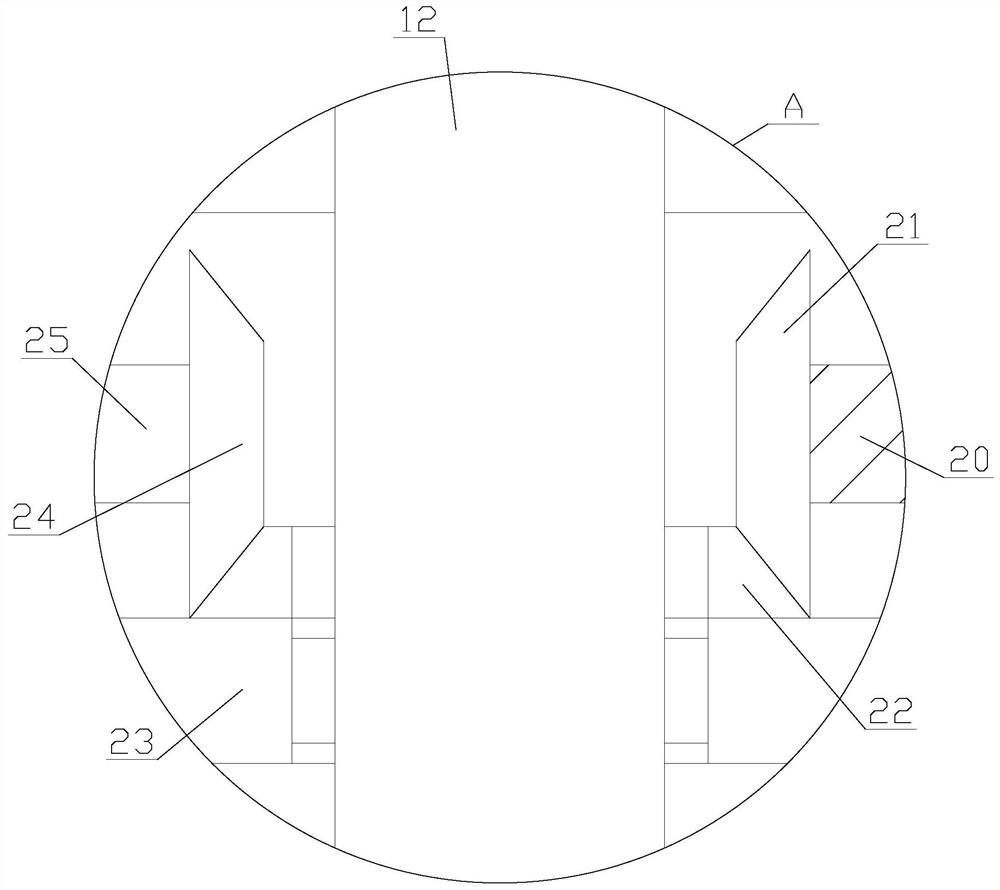

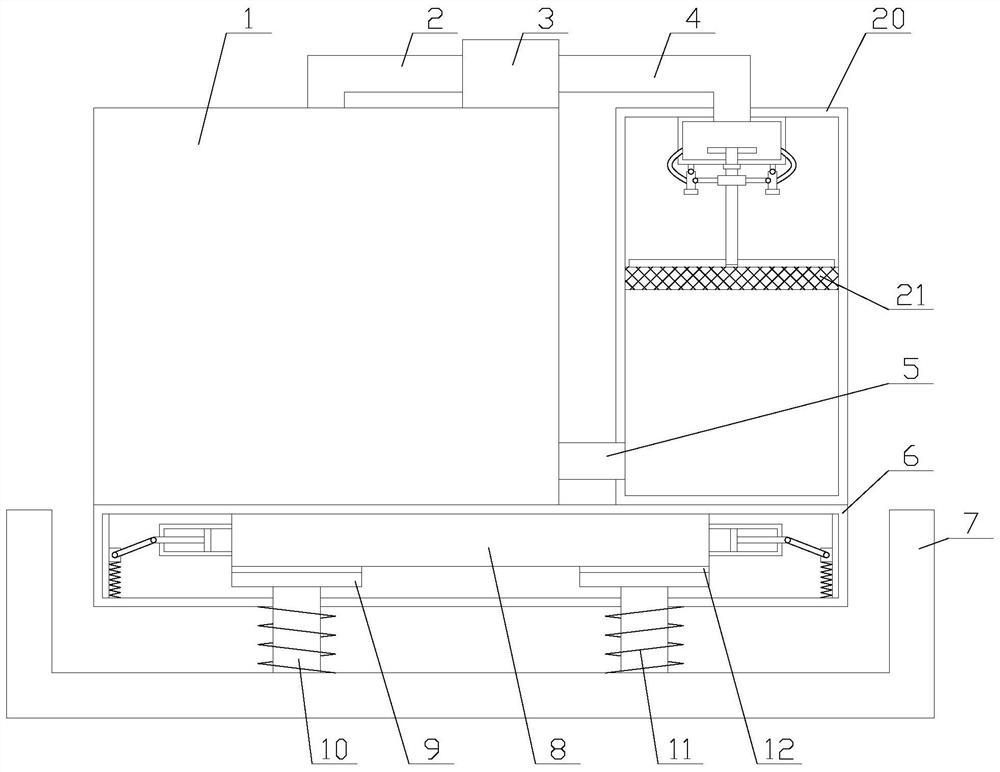

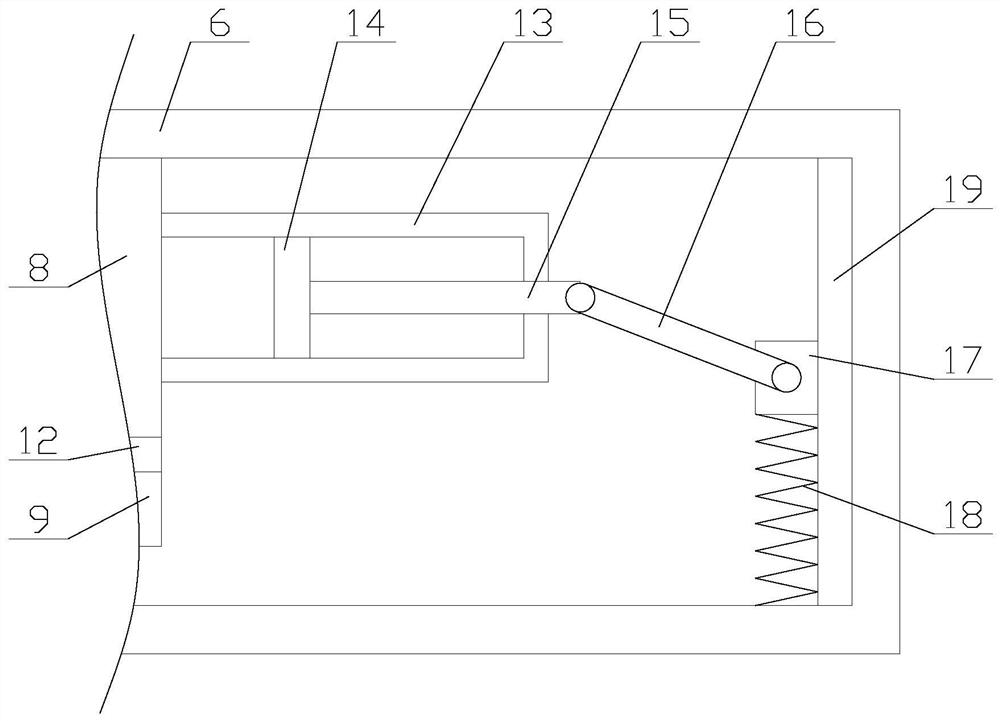

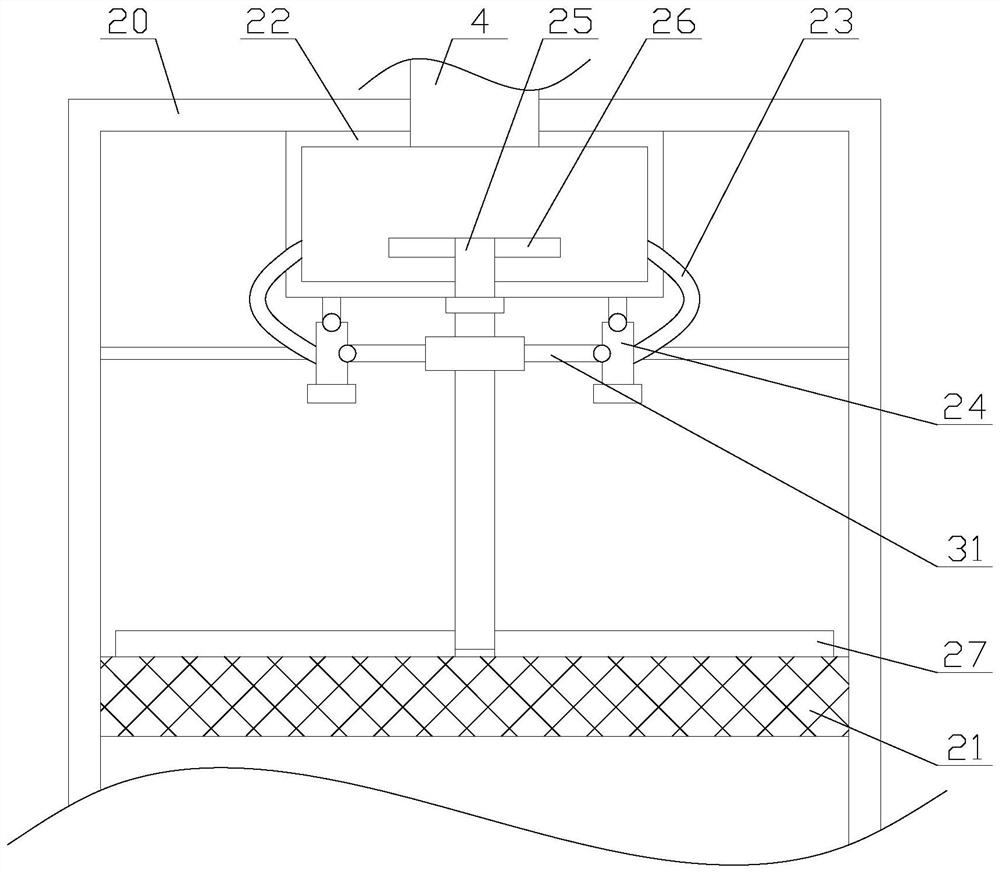

Hydraulic station with impurity removal function and good damping effect

ActiveCN110792645AReduce impuritiesQuality improvementServomotorsVibration suppression adjustmentsDamping functionHydraulic pump

The invention relates to a hydraulic station with an impurity removal function and a good damping effect. The station comprises a body, a base, a connection box, a damping mechanism, an impurity removal mechanism, an oil outlet pipe, a connecting pipe, an oil return pipe and a hydraulic pump, wherein the damping mechanism comprises an air bag, two damping assemblies and two auxiliary assemblies, the damping assemblies comprise damping rods, connecting plates and first springs, the impurity removal mechanism comprises an impurity removing box, a filter screen, a fixed box, a rotation assembly and two swing assemblies, and the swing assemblies comprise supporting shafts, nozzles and hoses. According to the hydraulic station with the impurity removal function and the good damping effect, theimpurity removal mechanism is used for conducting the impurity removal function on hydraulic oil, the impurity content in the hydraulic oil is reduced, the hydraulic oil quality is improved, the damping mechanism is arranged to realize a damping function on equipment, the shaking amplitude of the equipment is reduced, and the condition shaking is too large, so that normal work of the hydraulic station is affected is avoided.

Owner:DONGYING HENGYUAN MACHINERY MFG

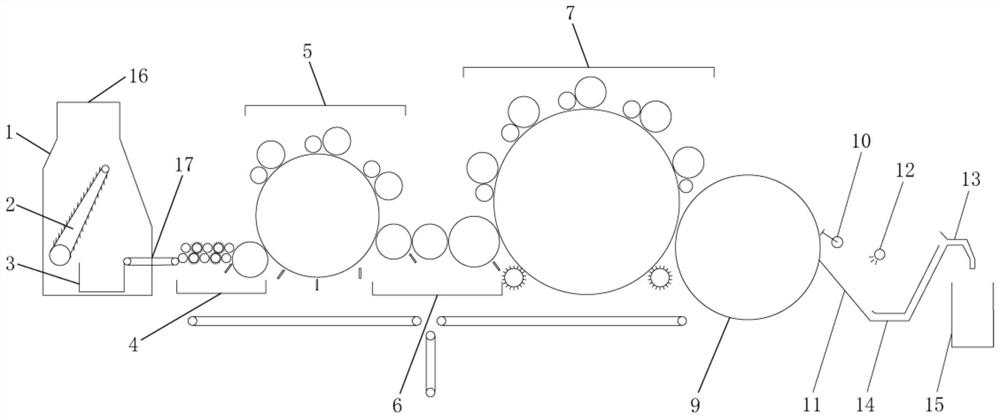

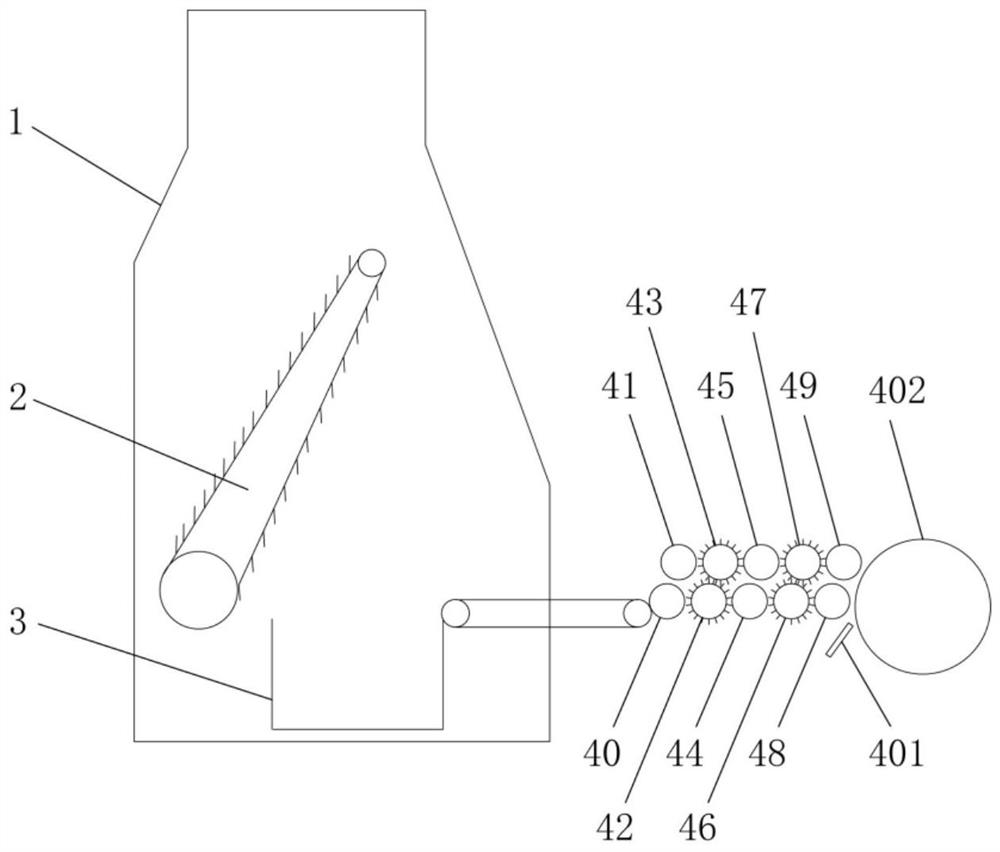

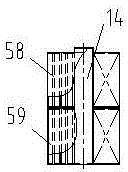

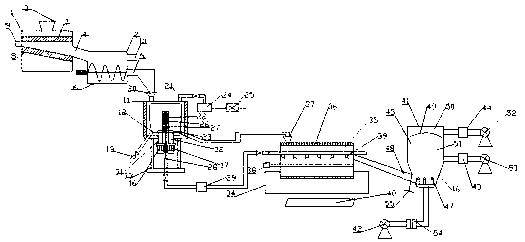

Intelligent wool carding, impurity removing and slivering combination machine

InactiveCN113046872AWith intelligent feeding functionWith opening functionContinuous processingCarding machinesCardingProcess engineering

The invention relates to the technical field of textile engineering mechanisms, in particular to an intelligent wool carding, impurity removing and slivering combination machine. The intelligent wool carding, impurity removing and slivering combination machine comprises a feeding mechanism, a feeding pre-opening mechanism, an opening and impurity removing mechanism, an impurity removing and transferring mechanism, a carding mechanism, a slivering and discharging mechanism and an intelligent control system. The feeding mechanism is used for grabbing cleaned wool and then evenly feeding the cleaned wool into the feeding pre-opening mechanism with constant weight, and the feeding pre-opening mechanism is used for opening the fed cleaned wool for the first time and then feeding the cleaned wool into the opening impurity removing mechanism. The opening and impurity removing mechanism is used for performing secondary opening and primary impurity removing on the fed cleaned wool and then feeding the wool into the impurity removing and transferring mechanism, the impurity removing and transferring mechanism is used for performing secondary impurity removing on the fed cleaned wool and then feeding the wool into the carding mechanism, the carding mechanism is used for carding the fed cleaned wool and then feeding the wool into the slivering and discharging mechanism, and the slivering and discharging mechanism is used for performing slivering and discharging on the fed cleaned wool.

Owner:WUHAN TEXTILE UNIV

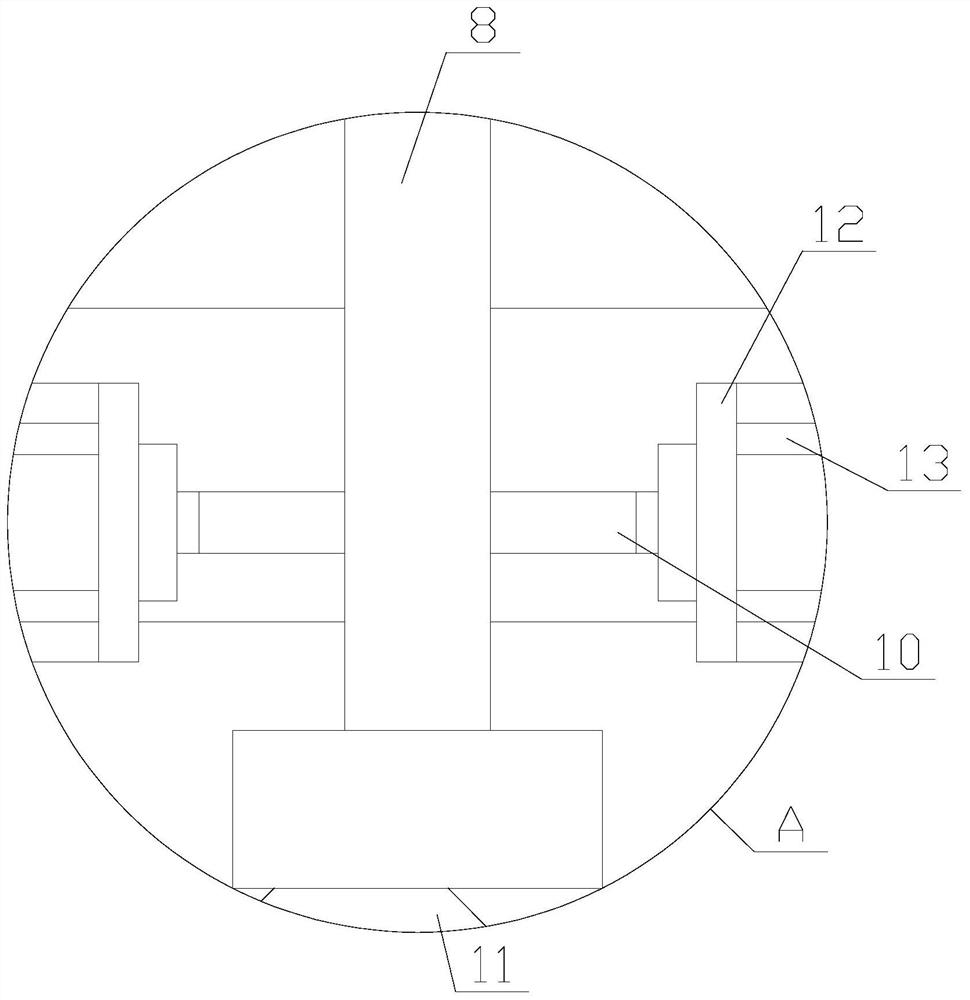

Yellow phosphorus mud ash recycling device with impurity removing function

InactiveCN108793109AAvoid reactionReduce the formation of impuritiesPhosphorus compoundsStationary filtering element filtersPropellerExhaust gas

The invention discloses a yellow phosphorus mud ash recycling device with an impurity removing function. The yellow phosphorus mud ash recycling device with the impurity removing function comprises animpurity removing filter chamber and a heating furnace, wherein a slurry pump is arranged above the impurity removing filter chamber; a water inlet is formed in the right side of the slurry pump; a stirring motor is arranged on the right side of a vacuum pump; a stirring propeller is arranged below the stirring motor; a residue discharging port is formed in the left side of the impurity removingfilter chamber; a filtering plate is arranged on the right side of the impurity removing filter chamber; the heating furnace is positioned below the impurity removing filter chamber; a yellow phosphorus tail gas connecting pipe is arranged on the side surface of the heating furnace; a phosphorus steaming boiler is arranged above the heating furnace; a yellow phosphorus steam pipe is arranged abovethe phosphorus steaming boiler; a cooling spray tower is arranged on the right side of the yellow phosphorus steam pipe. The yellow phosphorus mud ash recycling device with the impurity removing function is provided with the filtering plate, and during using, the filtering plate can filter liquid yellow phosphorus and impurities so as to reduce the impurities, so that increase in the purity of aproduct is facilitated.

Owner:贵州新天鑫化工有限公司

Sand blasting machine with impurity removal function

InactiveCN113400204AAchieve cloggingAvoid cloggingAbrasive machine appurtenancesGrinding/polishing apparatusSand blastingHeater Rod

The invention relates to a sand blasting machine with the impurity removal function. The sand blasting machine comprises a main body and a sand blasting device and further comprises an impurity removal mechanism and a drying mechanism, the impurity removal mechanism comprises a filter screen, a rotating ring, two shaking assemblies, two driving assemblies and a plurality of smashing assemblies, each smashing assembly comprises a nozzle, a fixing pipe and a plurality of sawteeth, and the drying mechanism comprises a rotating assembly, a stirring assembly, a connecting box, an impurity removal net, a power assembly, an air inlet pipe, an air outlet pipe and a plurality of heating rods. The sand blasting machine with the impurity removal function achieves the impurity removal purpose through the impurity removal mechanism, the probability that the sand blasting device is blocked by impurities is reduced, and therefore the sand blasting work cannot be affected, and the reliability of equipment is improved; and by means of the drying mechanism, the drying function is achieved, the situation that the sand blasting device is blocked due to the fact that materials affected with damp cake is prevented, and therefore the influence on normal sand blasting is avoided, and the reliability of the equipment is improved.

Owner:广州凌杭网络科技有限公司

Ultraviolet disinfection equipment with impurity removal function for water treatment

InactiveCN111470682AWith impurity removal functionRealization of impurity removal functionWater/sewage treatment by irradiationSpecific water treatment objectivesUv disinfectionSewage

The invention relates to ultraviolet disinfection equipment with an impurity removal function for water treatment. The equipment comprises a body, disinfection lamps, a water inlet box and a drain pipe. The equipment further comprises an impurity removing mechanism and a moving mechanism. The impurity removal mechanism comprises a filter cartridge, a rotating assembly, a cleaning assembly and a limiting assembly; the cleaning assembly comprises a connecting rod and two scraping rods; the moving mechanism comprises a driving assembly, a first moving plate, a second moving plate, two connectingassemblies and a plurality of springs. The ultraviolet disinfection equipment with the impurity removal function for water treatment has the advantages that the impurity removing mechanism is arrangedto realize the function of removing impurities in sewage, so impurities in the sewage are prevented from influencing irradiation light of the disinfection lamp, and the sewage treatment effect is improved; the sewage flows from inside to outside and then from outside to inside through the moving mechanism, the sewage makes full contact with the irradiation light of the disinfection lamps, and thesewage treatment effect is improved.

Owner:南京昕知环保科技有限公司

Metal extraction device with impurity removal function

InactiveCN106636663AWith impurity removal functionHigh purityProcess efficiency improvementRotation functionEngineering

The invention discloses a metal extraction device with an impurity removal function. The metal extraction device comprises a machine body, wherein motors are respectively and fixedly arranged at both sides of the inner wall of the machine body; an output end of each motor is fixedly connected with a connecting belt; one end of the connecting belt is fixedly connected with a hanging ring; the bottom part of the hanging ring is fixedly connected with a filtering plate; one side of the filtering plate is glidingly connected with a slide rail; one side of the slide rail is fixedly connected with the inner wall of the machine body. The metal extraction device has the advantages that by arranging the motor, the slide rail, sleeve cylinders, springs and fixed plates, raw stones are fed through the top part of the machine body, and fall onto the filtering plate, the motor with positive and reverse rotation functions is started to drive the connecting plate to rotate, and then the filtering plate at the bottom parts of the hanging rings is driven to slide up and down on the slide rail, so as to drive the springs at the bottom part of the filtering plate to be compressed and extended, and enable the filtering plate to oscillate up and down; impurities in the raw stones are separated from metal by oscillation, so as to improve the purity of the metal.

Owner:李理

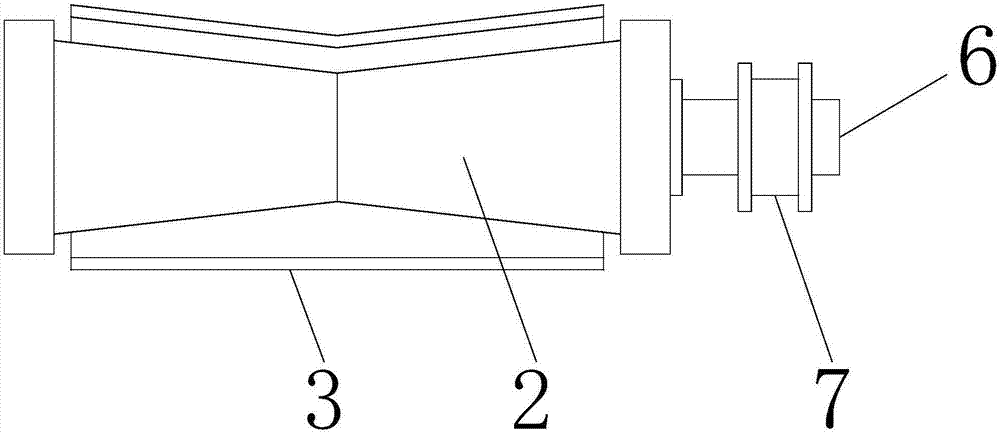

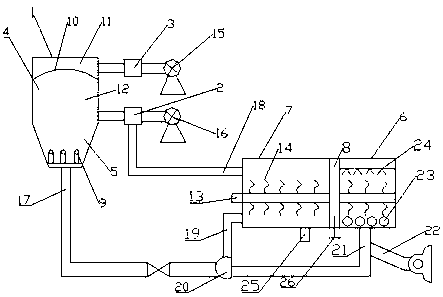

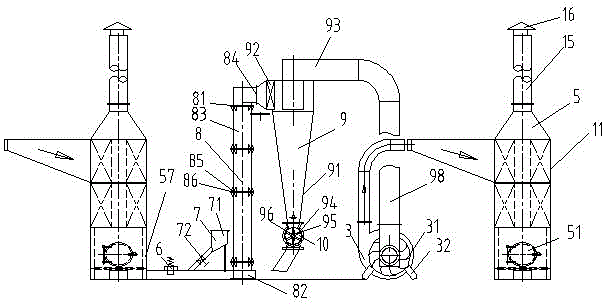

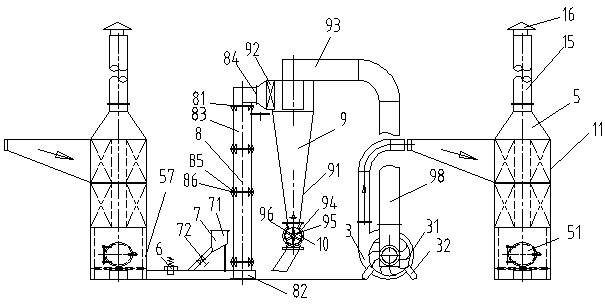

Cyclone type flashing drying machine for oilseed rapes

InactiveCN105222557AExtension of timeFull heat exchangeDrying gas arrangementsDrying solid materialsThermodynamicsHot air oven

The invention discloses a cyclone type flashing drying machine for oilseed rapes. The cyclone type flashing drying machine comprises a drive mechanism, a high-pressure centrifugal fan, a spiral-plate type hot blast heater, a valve type feeding device, a drying device, a cyclone collection device and a star-type discharging device. An air outlet of the hot blast stove is connected with the lower end of a pipe of the valve type feeding device and an inlet of an annular channel at the bottom end of a drying cylinder. The top of the cyclone collecting device is provided with a spiral airflow inlet pipe and an air guide and outlet pipe which are connected with the drying device and an inlet pipe of a fan. The lower end of the cyclone collection device is connected with the star type discharging device through a trapped pipe on the lower portion of the cyclone collection device. The spiral plate type hot blast stove comprises a spiral plate type heat exchanger which is provided with at least a pair of spiral channels arranged in a spaced manner so that cold fluid and heat fluid can flow helically and flow upwards in two runners respectively. By means of the structure, the heat utilization rate is high, and clean airflow can be obtained; meanwhile the valve type feeding device is adopted, no devices for stirring, chopping and the like are adopted, and the quality and integrity of material particles in the feeding and drying processes when the drying machine operates are guaranteed.

Owner:HUNAN AGRICULTURAL UNIV

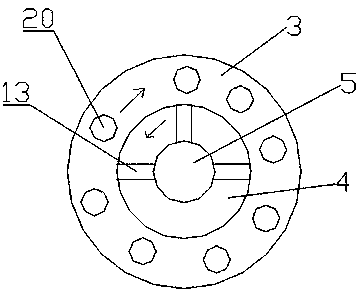

Sesame seed peeling equipment capable of performing drying

InactiveCN107865450AFast and efficient dryingImprove peeling efficiencyGas current separationVegetable peelingSesamum orientaleVertical tube

The invention discloses a sesame peeling device with drying, which includes a peeling device and a drying device. The peeling device includes a vertical cylinder and an inner cylinder. The turntable and the outer disk have the same center of circle, and the rotation direction of the turntable is opposite to that of the outer disk. The drying device includes a drying barrel, an air supply device, a collection chamber and an impurity chamber. Through the sesame peeling device with drying of the present invention, the sesame is thoroughly peeled, the efficiency of sesame peeling is improved, and the damage rate in the process of sesame peeling is reduced at the same time, the sesame is quickly and effectively dried, and the color and luster of the sesame are guaranteed. degree, to ensure the quality of the finished product.

Owner:黄林海

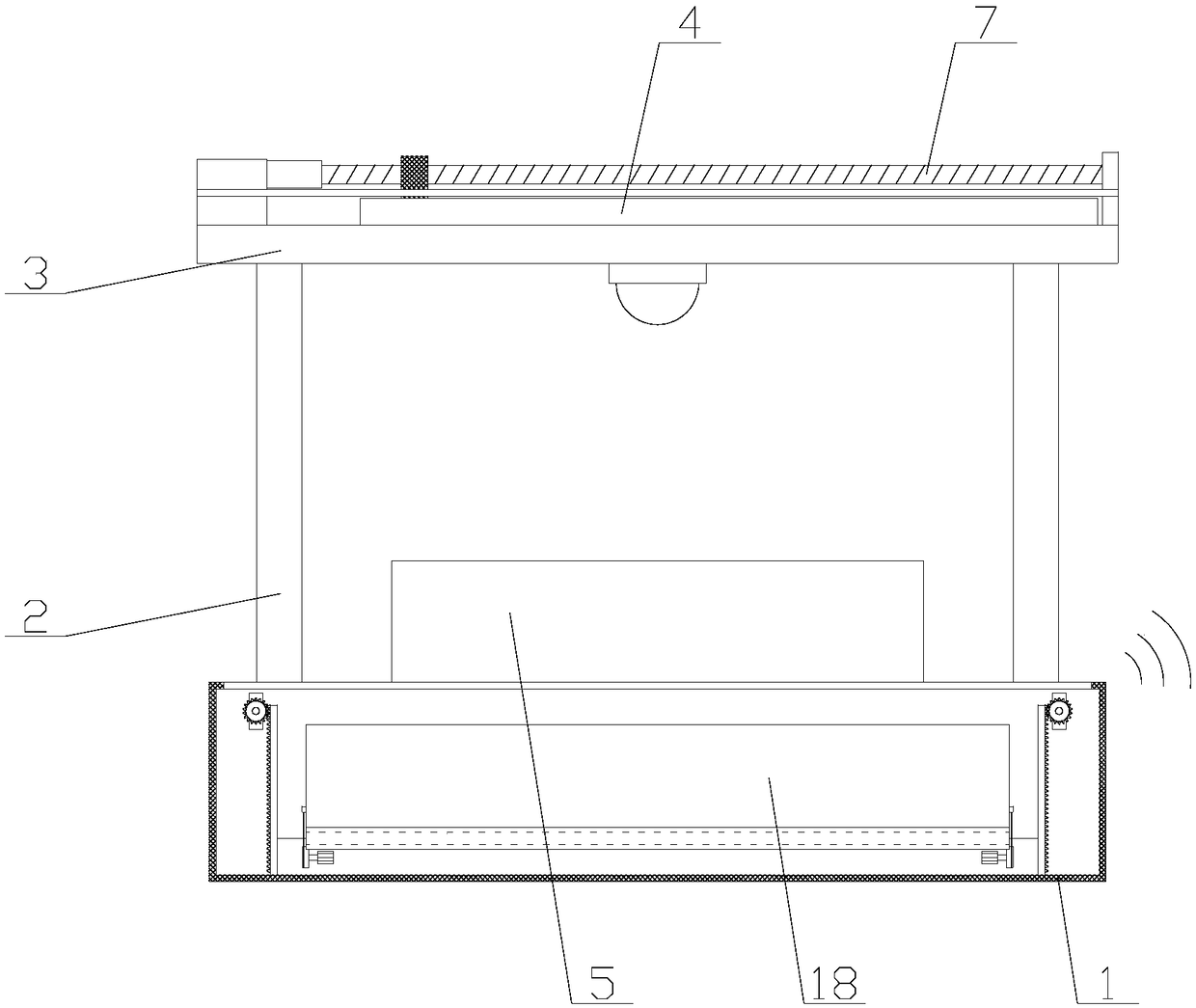

Intelligent bus station having impurity removal and water prevention functions

ActiveCN108847819AImprove practicalityImprove reliabilityPhotovoltaicsSpecial buildingImpurityElectrical and Electronics engineering

The invention relates to an intelligent bus station having impurity removal and water prevention functions. The intelligent bus station comprises a base, studs, a ceiling, a photovoltaic panel and a seat and also comprises an impurity removal mechanism and a water prevention mechanism, wherein the impurity removal mechanism comprises a cleaning assembly and a washing assembly, and the water prevention mechanism comprises a splash-prevention assembly and a turnover assembly. In the intelligent bus station having impurity removal and water prevention functions, cleaning of a cleaning strip on asurface of the photovoltaic panel can be controlled by the impurity removal mechanism, a nozzle is simultaneously controlled to spray water and wash so as to further improve the impurity removal effect, the situations that sunlight cannot be in direct contact with the photovoltaic panel caused by impurity coverage and the power generation effect of the photovoltaic panel are prevented, and impurity removal is more efficient and convenient; by the water prevention mechanism, a bottom plate can be controlled to extend out of the base in a rainy day, splashing accumulated water is shielded, and the clothing of people is prevented from being wet; and moreover, people is convenient to step a baffle plate and enter a bus, the people is more convenient to take a bus, and the practicability and the reliability of the bus station are greatly improved.

Owner:江苏彩虹智能公共设施有限公司

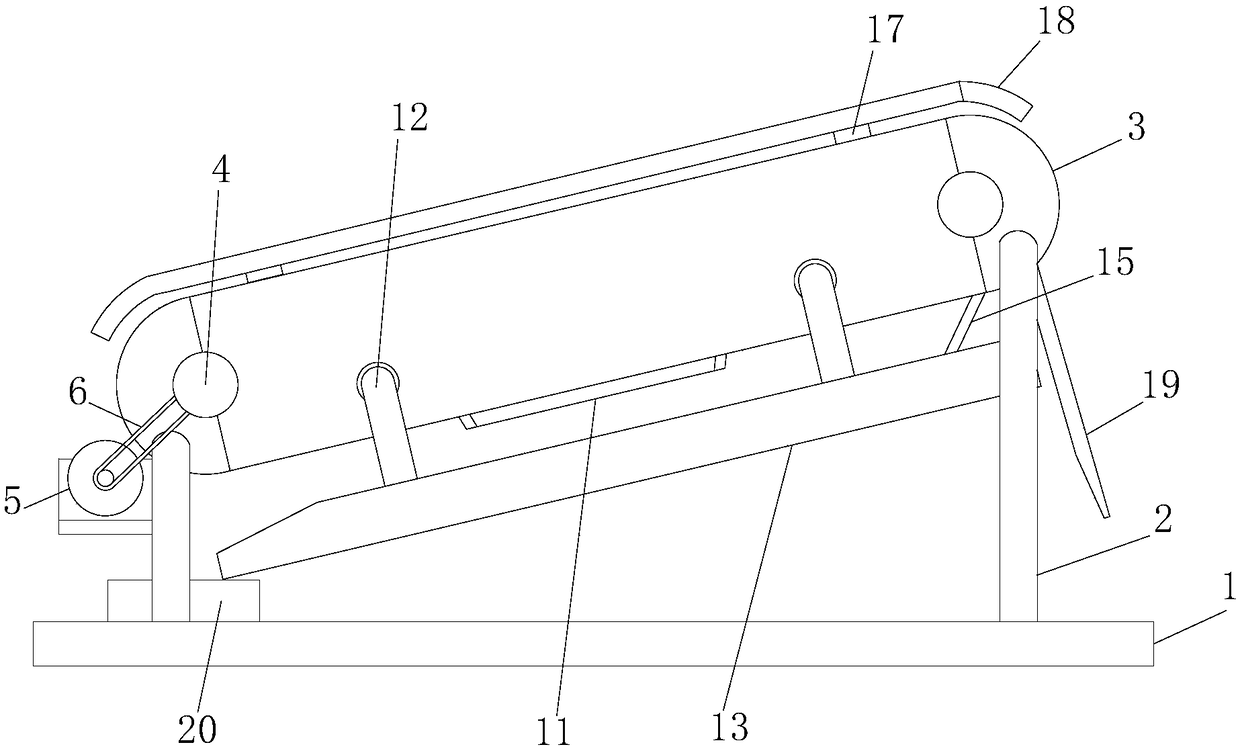

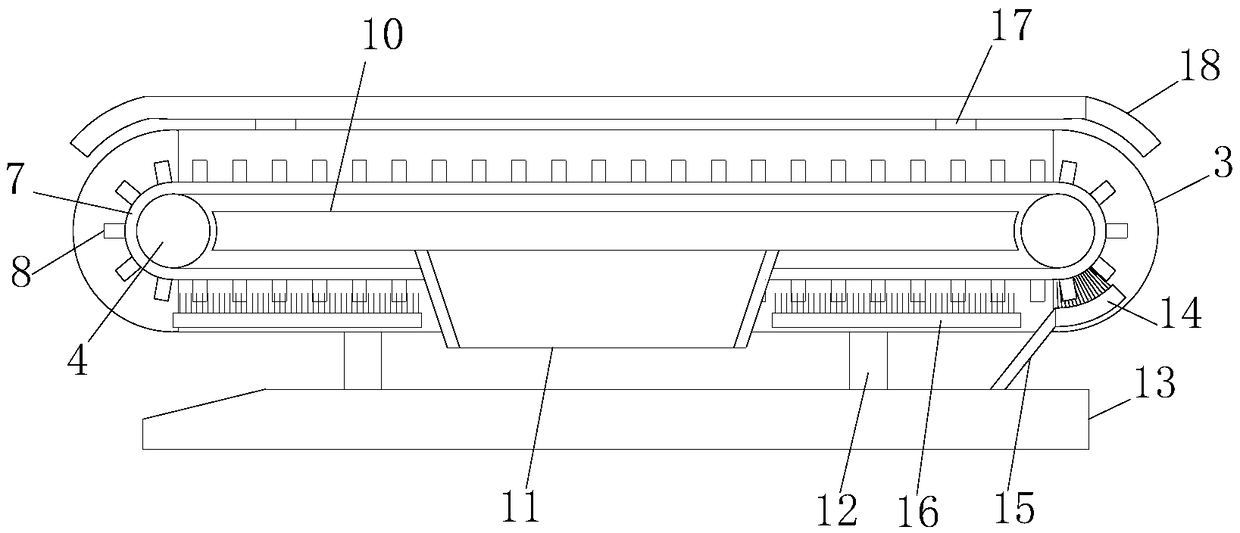

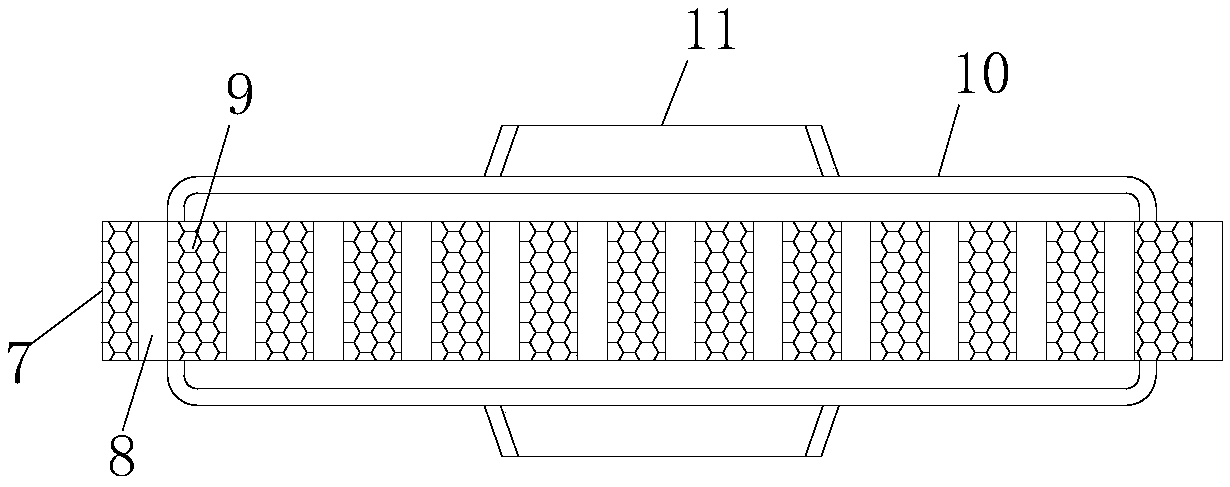

Sand stone conveyor with impurity removing function

InactiveCN109230209AImprove the efficiency of impurity removalAvoid cloggingSievingConveyorsEngineeringSieve

The invention discloses a sand stone conveyor with an impurity removing function. The sand stone conveyor comprises a base seat, supporting legs are symmetrically welded on a top part of the base seat, a fixed baffle plate is symmetrically welded on top parts of the supporting legs, rotating shafts are movably connected on left and right sides of the fixed baffle plate in a plugged manner, an electric motor is mounted on the supporting leg on a left side of the top part of the base seat, a transmission belt is connected between an output end of the electric motor and the rotating shaft positioned on a left side of the fixed baffle plate, a conveyor belt is connected between the rotating shafts in a transmitted manner, toothed plates are mounted on the conveyor belt at equal intervals, theconveyor belt is provided with sieve holes that are arranged at equal intervals, and a collecting box is arranged between the rotating shafts. In the sand stone conveyor with the impurity removing function, impurities such as gravels and the like in sand stones can be separated via arrangement of a mechanism convenient for impurity removal with normal sand stone conveying remaining unaffected, separated impurities can be conveniently discharged via gravity of the sand stones, and impurity removing efficiency can be improved.

Owner:湖州全优电工材料有限公司

Quenching furnace with impurity removal function

InactiveCN112593060AWith impurity removal functionRealization of impurity removal functionTransportation and packagingRotary stirring mixersElectric machineDrive shaft

The invention relates to a quenching furnace with an impurity removal function. The quenching furnace comprises a main body, a cover plate, a heating chamber, a lifting plate, a quenching chamber, twoair cylinders, a stirring mechanism and an impurity removal mechanism, wherein the impurity removal mechanism comprises a filter screen, a transmission assembly, two driving assemblies and two impurity removal assemblies; each impurity removing assembly comprises a circular ring, a collecting box, a connecting pipe, a first branch pipe, a second branch pipe, a piston, a spring, a fixing ring, a first bearing, two fixing rods and a plurality of suction nozzles; each driving assembly comprises a transmission shaft, a one-way bearing, a driving shaft, a driving disc, a driving rope and two second bearings; and the stirring mechanism comprises a motor, a stirring shaft, a transmission gear, a third bearing and a plurality of stirring plates. According to the quenching furnace with the impurity removal function, the impurity removal function on quenching liquid is achieved through the impurity removal mechanism, the situation that impurities in the quenching liquid influence the quenchingquality is avoided, and the stirring function on the quenching liquid is achieved through the stirring mechanism, so that a workpiece makes full contact with the quenching liquid, and accordingly thequenching efficiency is improved.

Owner:魏欣菊

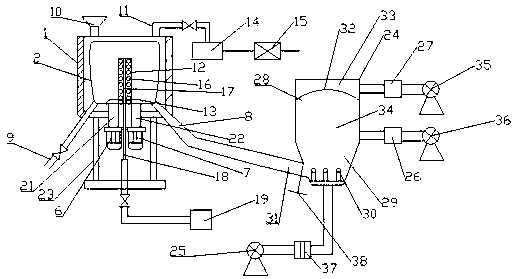

Processing system for sesame seeds used for preparing sesame seed candies

InactiveCN107751928AQuality assuranceImprove peeling efficiencyHuskingHullingSesamum orientaleBreakage rate

The invention discloses a sesame treatment system for sesame sugar, which comprises a decontamination device, a peeling device, a separation device and a drying device. A sesame auger is installed in the immersion tank, the peeling device includes a vertical cylinder and an inner cylinder, the separation device includes a fixed frame and a water spray pipe, a sieve bucket is installed on the fixed frame, and the drying device includes a drying bucket, an air supply device, a collection room and impurities. room. Through the sesame treatment system for sesame sugar of the present invention, the impurities in the sesame can be completely removed, the sesame can be completely separated from the skin kernel, the damage rate in the process of peeling the sesame can be reduced, and the sesame can be quickly and effectively dried, and the sesame can be guaranteed Sesame color and gloss ensure the quality of finished products.

Owner:黄林海

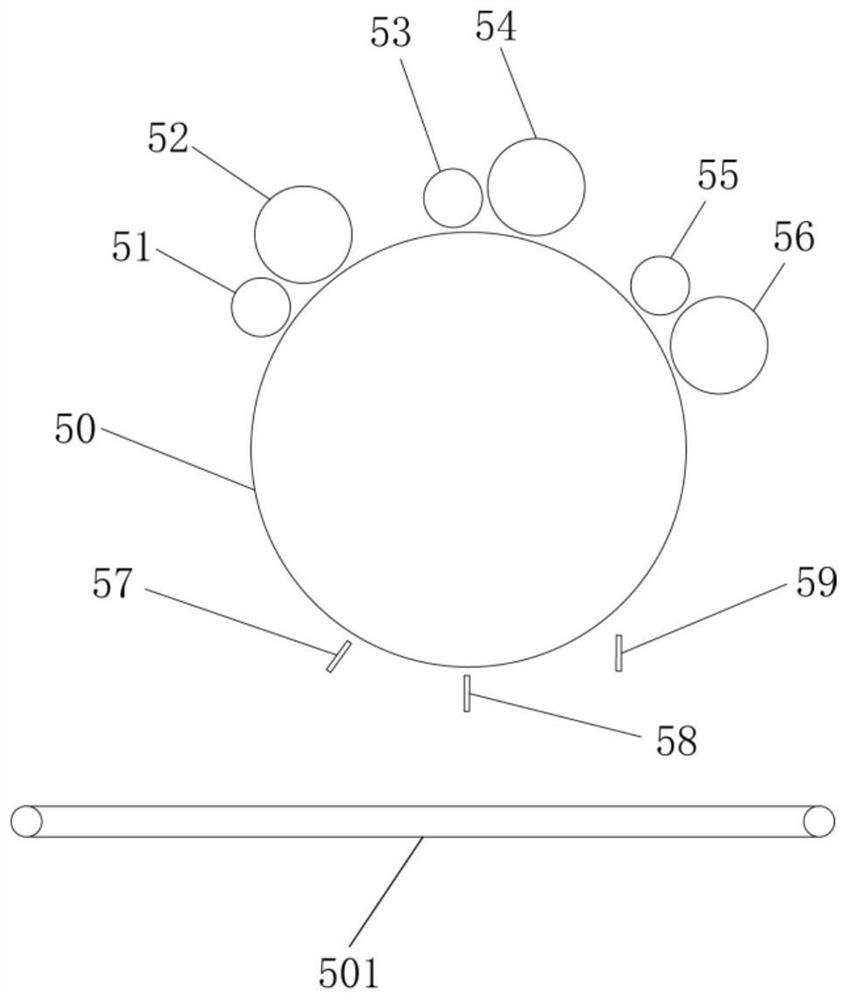

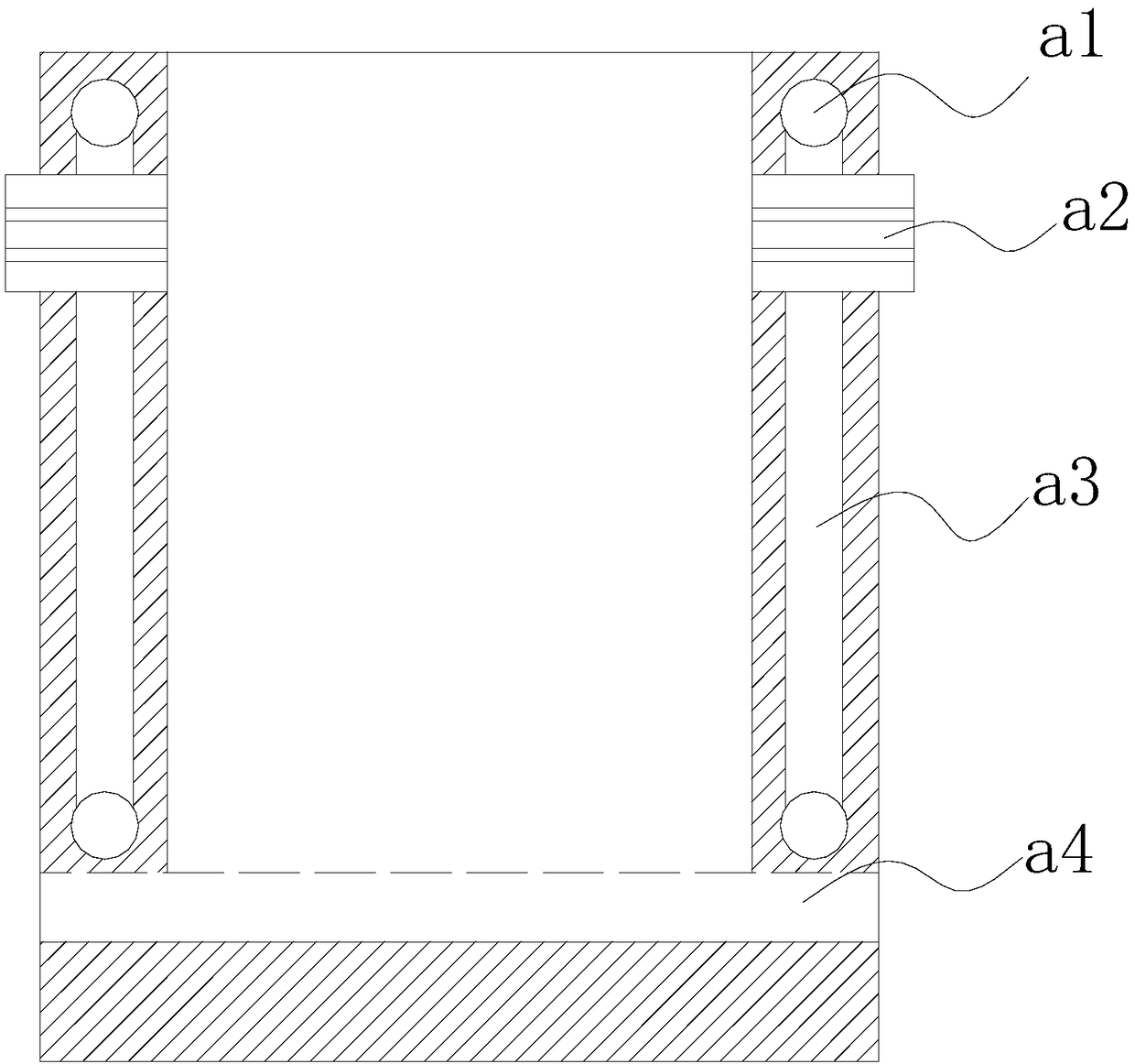

Cashmere carding machine with impurity removing function

PendingCN109338520AWith impurity removal functionProtection against impuritiesCarding machinesEngineeringDrive motor

The invention discloses a cashmere carding machine with an impurity removing function. The cashmere carding machine comprises machine plates, a blocking cover, a driving motor and an air blowing machine, the two machine plates are symmetrically arranged on the machine plates, and doffers and cylinders are arranged in the machine plates in parallel; the doffers are arranged on the cylinders, the blocking cover is arranged on the upper surfaces of the machine plates and is of a cuboid structure, and the blocking cover and the two long sides flush with the upper surfaces of the machine plates arein hollow arrangement; grooves are formed in the upper surfaces of the machine plates, an air pipe is embedded in the grooves and arranged horizontally, and a plurality of through holes arranged in aline form are formed in the surface, facing the blocking cover, of the air pipe; spraying heads are installed in the through holes, and the spraying sections of the spraying heads are in a triangle shape spreading outward. The cashmere carding machine with the impurity removing function is reasonable in structure, has the advantages that wool spraying is reduced, and the production environment can be protected, and can be used widely.

Owner:河北杰格布羊绒纺织有限公司

Electroplating equipment with impurity removal function

The invention relates to electroplating equipment with an impurity removal function. The electroplating equipment comprises a bottom plate, a main body, a top plate, a hook, two lifting devices, four support blocks, an impurity removal mechanism and two stirring mechanisms, wherein the impurity removal mechanism comprises an impurity removal box, a filter screen, a connecting pipe and two circulating assemblies, the stirring mechanism comprises a moving plate, a first limiting rod, a second limiting rod, a first spring and two transmission assemblies. According to the electroplating equipment with the impurity removal function, through the impurity removal mechanism, the function of removing impurities from a plating solution is achieved, the impurity content of the plating solution is reduced, the influence on the electroplating quality is avoided, and therefore the reliability of the equipment is improved; and through the stirring mechanism, the function of stirring the plating solution in the main body is realized, and the flowing speed of the plating solution is increased, so that the speed of covering a workpiece with the plating solution can be increased, the electroplating working efficiency is improved, the reliability of equipment is improved, cations in the plating solution are uniformly distributed, and the electroplating quality is improved.

Owner:南京鸿音工程技术有限公司

Melting device for rotary blowing in waste glass recycling

InactiveCN108975656AWith centralized adsorption functionLower installation heightGlass furnace apparatusGlass productionSlagControl room

The invention discloses a melting device for rotating blowing in waste glass recycling. A structure of the melting device comprises supporting legs, a melting chamber, a feeding tray, a slag outlet, adischarge opening, and a control chamber. The melting chamber and the control chamber are an integrated structure, the feeding tray is vertically welded at the upper end of the melting chamber and located at the right end of the control chamber, and the discharge opening is fixedly welded at the left end of the melting chamber at 45 degrees. A fan blade and a rotating shaft realize the dispersalof suspended matters to enable the suspended matters to converge on both sides, and the converged suspended matters are adsorbed by oil-absorbing sheets fastened on sliding plates on the two sides, and finally the sliding plates discharge the contaminated oil-absorbing sheets through a partition groove to the slag outlet along a sliding track. The melting device realizes that the melting device with a function of removing impurities, and ensures the high purity and pure color of a glass solution.

Owner:林学琴

A hydraulic station with a function of removing impurities and a good shock absorption effect

ActiveCN110792645BImprove shock absorptionAffect normal workServomotorsVibration suppression adjustmentsHydraulic pumpEngineering

The invention relates to a hydraulic station with a good shock absorption effect with the function of removing impurities, which includes a main body, a base, a connection box, a shock absorbing mechanism, a removing mechanism, an oil outlet pipe, connecting pipes, an oil return pipe and a hydraulic pump. The shock mechanism includes an air bag, two shock absorbing assemblies and two auxiliary assemblies. The shock absorbing assembly includes a shock absorbing rod, a connecting plate and a first spring. assembly and two swing assemblies, the swing assembly includes a support shaft, a nozzle and a hose, the hydraulic station with a good shock absorption effect with the impurity removal function performs an impurity removal function on the hydraulic oil through the impurity removal mechanism, reducing the hydraulic pressure The impurity content in the oil improves the quality of the hydraulic oil. Through the shock-absorbing mechanism, it realizes the function of shock-absorbing the equipment, reduces the shaking range of the equipment, and avoids excessive shaking that affects the normal operation of the hydraulic station.

Owner:DONGYING HENGYUAN MACHINERY MFG

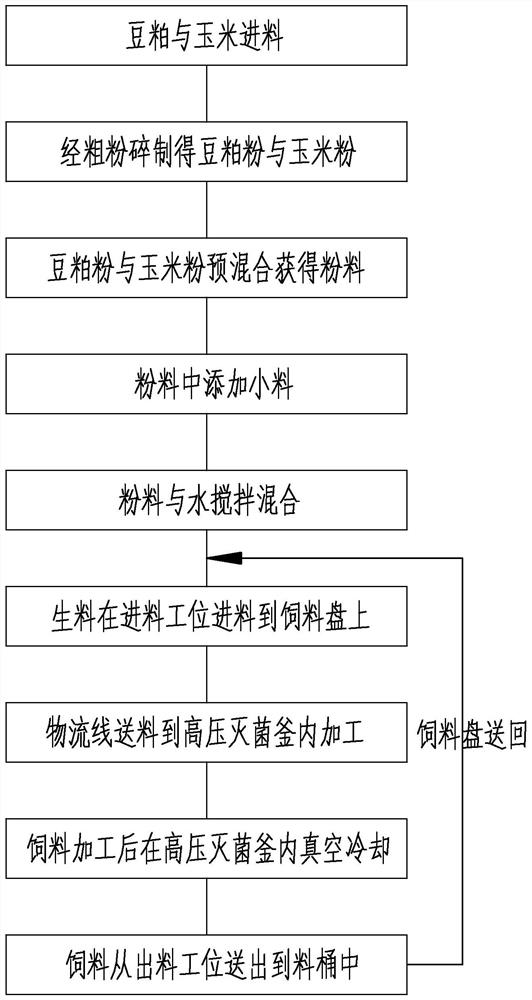

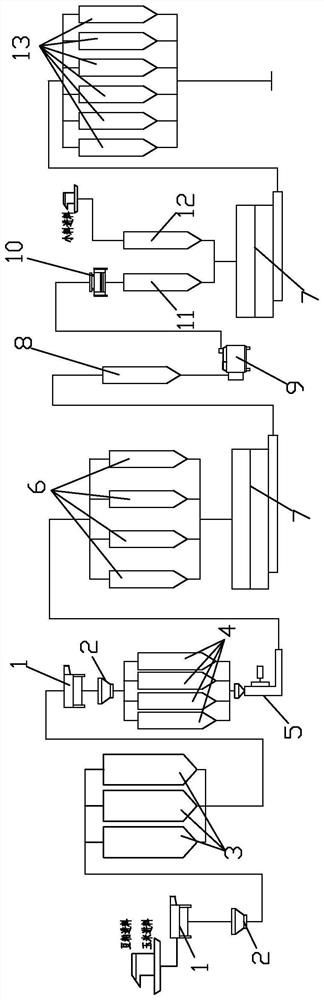

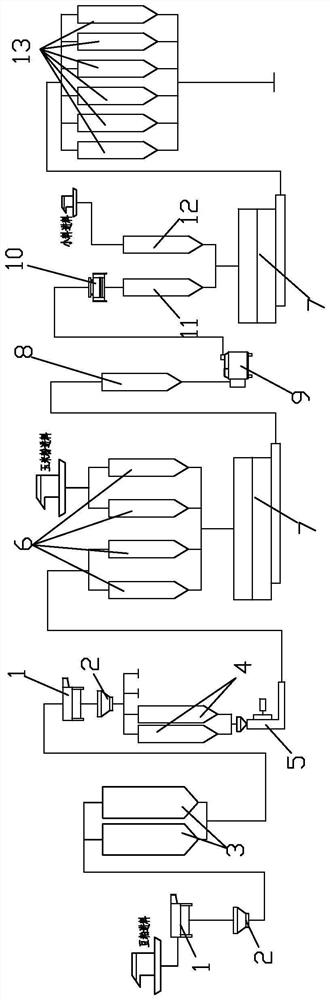

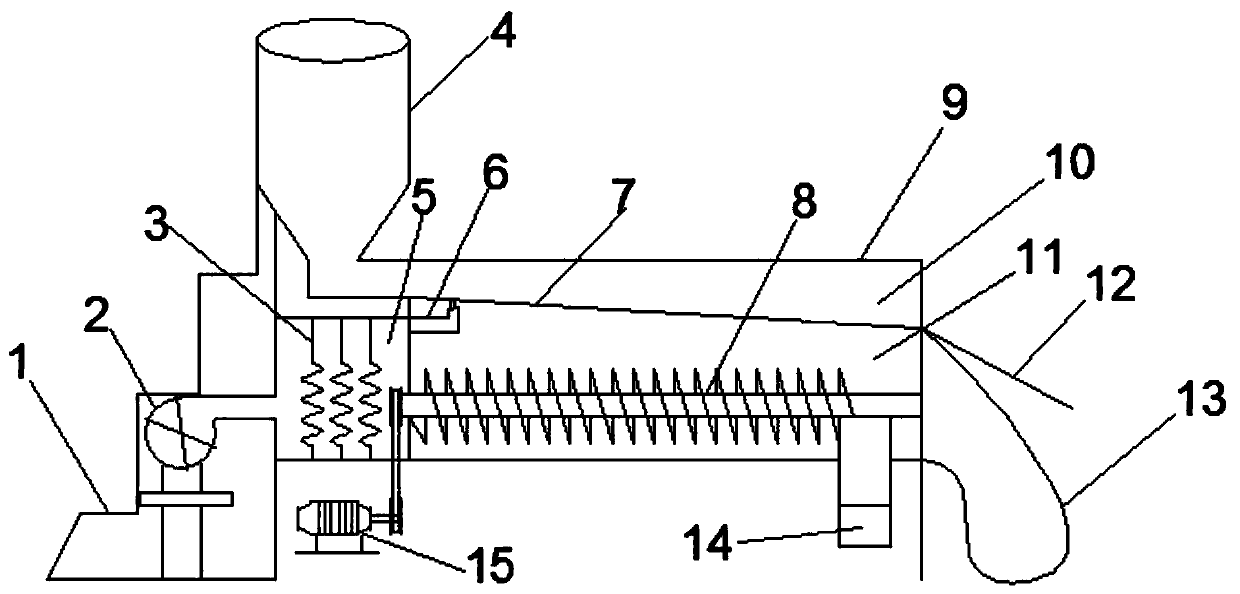

High-pressure sterilization type artificial feed production process applied to industrial silkworm breeding

PendingCN114258982AIncrease productivityEasy to digestFood processingAnimal feeding stuffFeed processingProcess engineering

The invention discloses a high-pressure sterilization type artificial feed production process applied to industrial silkworm breeding, which comprises the following steps: (1) raw material treatment: crushing raw materials, and mixing the crushed raw materials to obtain powder; (2) feed processing: mixing and stirring the powder and water, and performing high-pressure sterilization processing to obtain the feed; and (3) cooling the feed. A systematic and continuous production method is designed and comprises three coherent steps of raw material treatment, processing and feed cooling, uniformly mixed powder is obtained after raw material treatment, the powder and water are stirred and mixed, the feed is processed and cooled in a high-pressure sterilization mode, the purpose of large-scale, systematic and continuous feed production is achieved, and the production efficiency is improved. And the production efficiency is obviously improved. The high-pressure sterilization mode can achieve sterilization and disinfection effects on the feed, the content of bacteria on the surface of the feed is controlled, silkworms are easy to digest after eating the feed, and the illness probability is remarkably reduced.

Owner:SHENGZHOU MOSANG HI TECH CO LTD

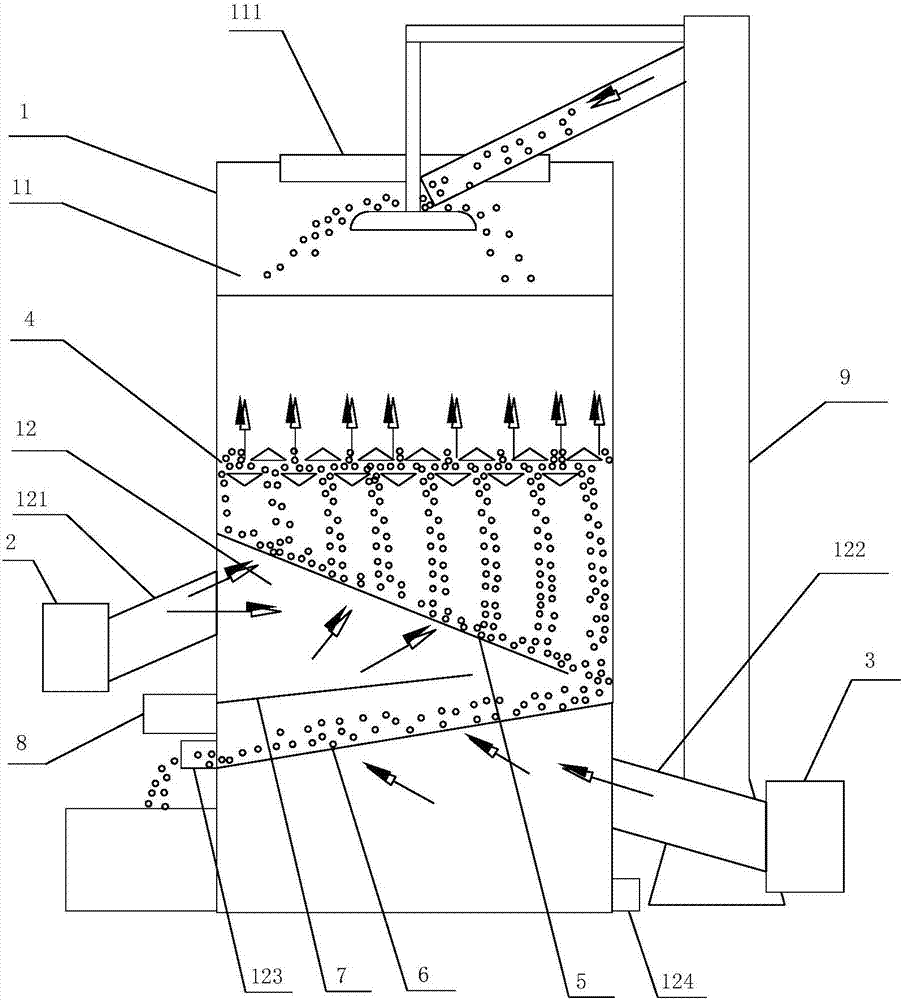

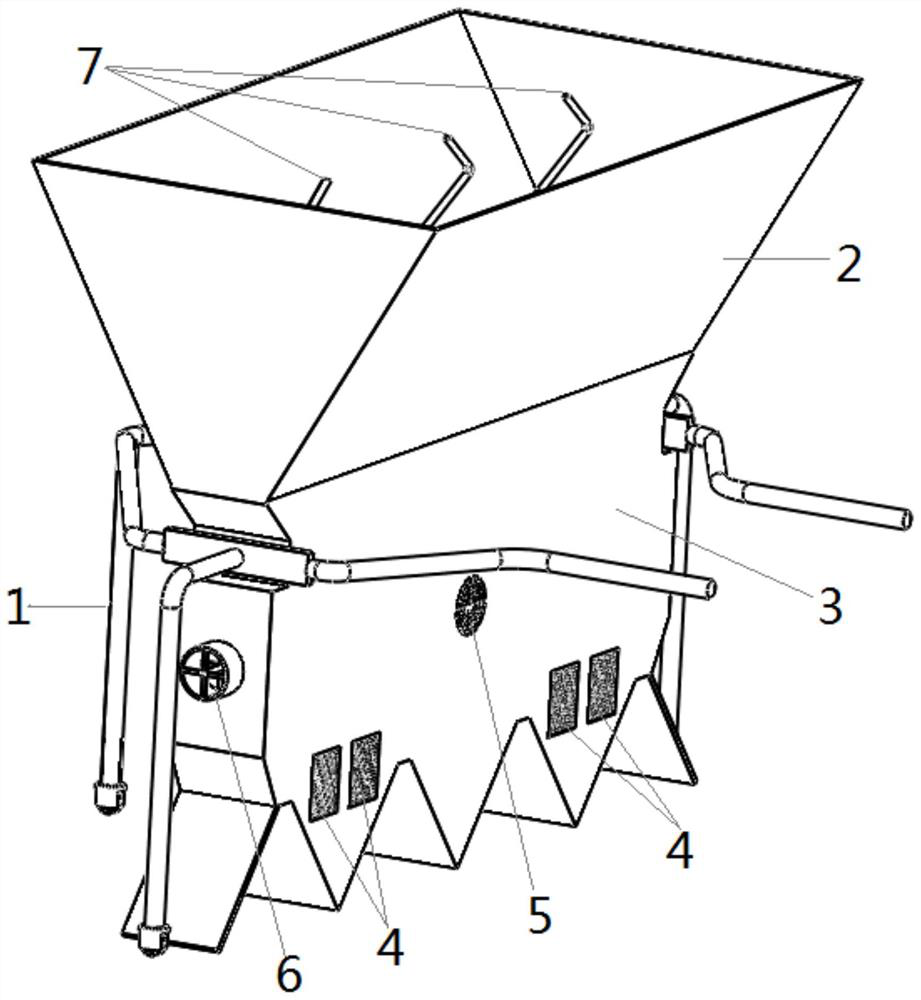

Granular crop impurity removing and drying integrated machine

The invention discloses a granular crop impurity removing and drying integrated machine. The machine comprises a machine body, a bin body, an air blower, a heating device, a spiral stirring wheel anda screen, the bin body is arranged at the upper left portion of the machine body, and the machine body is provided with a heating chamber, a drying chamber and an impurity removing layer; the heatingdevice is arranged in the heating chamber, the air blower is connected with the heating chamber, and the spiral stirring wheel is arranged in the drying chamber, and the impurity removing layer is arranged above the drying chamber. The impurity removing and drying integrated machine is suitable for the general small-yield farmers, in the autumn harvest season, by depending on the conventional weather airing, the crops get wet in the rain and are washed away due to the untimely rush harvesting when encountering a shower, and are easy to go bad and even go mouldy when being stacked together fora long time, in order to solve the above problems, the granular crop impurity removing and drying integrated machine can be dried in a room, can conduct impurity removal and drying operations on different crops, such as peanuts, wheat, rice, etc., can reduce the waste of the crops, guarantees that the crops are smoothly put into storage after being dried, saves time and labor, and greatly improvesthe autumn harvest efficiency.

Owner:ANHUI HUACHUANG MODERN AGRI TECH

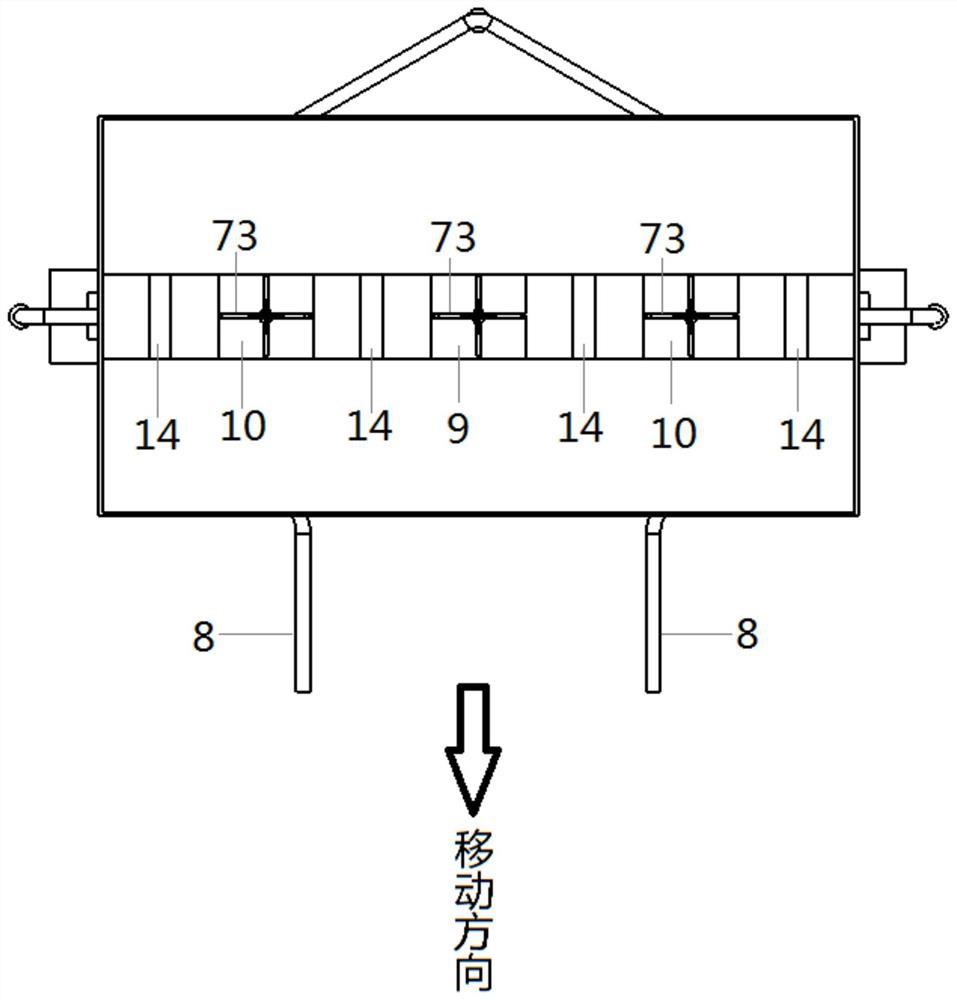

Grain drying device and drying method thereof

ActiveCN108477296BImprove functionalityWith impurity removal functionSeed preservation by dryingStructural engineeringMechanical engineering

The invention discloses a grain drying device and a drying method thereof, which include a tripod and a grain temporary storage and distribution device, and the grain temporary storage and distribution device includes a temporary storage feeding port and a grain distribution box connected as an integral structure. The temporary storage opening is a prism-shaped structure with a large upper part and a smaller lower part. The grain distribution box includes a first box body arranged inside it and two second box bodies arranged symmetrically with respect to the first box body. One box and two second boxes, one side box wall of one of the second boxes and its adjacent grain distribution box, and the other side box wall of the other second box and its adjacent grain distribution box all form a grain The diversion shaping channel is used to divert and shape the temporarily stored grain in the temporary feeding port through the grain diversion shaping channel under the action of gravity. The invention can remove the impurity in the grain tanning process, and shape the grain to form a grain hump in the shape of an isosceles trapezoid, increase the light-receiving area of the grain, and improve the grain tanning efficiency.

Owner:湖南怡田美农业科技有限公司

Multi-stage screening type tea winnowing machine with impurity removal function

PendingCN114653589AWith impurity removal functionEasy feedingGas current separationMechanical engineeringTea leaf

The multi-stage screening type tea winnowing machine with the impurity removing function comprises a machine body, supporting legs are fixedly connected to the four corners of the bottom end of the machine body, an impurity discharging opening is fixedly connected to one side of the bottom end of the machine body, and a discharging opening is fixedly connected to the other side of the bottom end of the machine body; three sets of screening plates are movably hinged to the interior of the machine body, and four sets of screening fans are installed on the two sides of the interior of the machine body. According to the multi-stage screening type tea winnowing machine with the impurity removing function, the screening plates can be driven to vibrate up and down through bounce of the telescopic rods and the connecting springs, and tea leaves obtained after winnowing enter the second set of screening plates to be winnowed till being discharged from the discharging opening; according to the tea winnowing machine, multi-layer screening is achieved through the three sets of screening plates, the impurity removal effect is enhanced, the tea winnowing quality is improved, and the problem that the impurity removal effect is poor is solved.

Owner:安化县银峰茶业有限责任公司

Rapeseed cyclone flash dryer

InactiveCN105222557BExtension of timeFull heat exchangeDrying gas arrangementsDrying solid materialsCycloneThermal energy

The invention discloses a cyclone type flashing drying machine for oilseed rapes. The cyclone type flashing drying machine comprises a drive mechanism, a high-pressure centrifugal fan, a spiral-plate type hot blast heater, a valve type feeding device, a drying device, a cyclone collection device and a star-type discharging device. An air outlet of the hot blast stove is connected with the lower end of a pipe of the valve type feeding device and an inlet of an annular channel at the bottom end of a drying cylinder. The top of the cyclone collecting device is provided with a spiral airflow inlet pipe and an air guide and outlet pipe which are connected with the drying device and an inlet pipe of a fan. The lower end of the cyclone collection device is connected with the star type discharging device through a trapped pipe on the lower portion of the cyclone collection device. The spiral plate type hot blast stove comprises a spiral plate type heat exchanger which is provided with at least a pair of spiral channels arranged in a spaced manner so that cold fluid and heat fluid can flow helically and flow upwards in two runners respectively. By means of the structure, the heat utilization rate is high, and clean airflow can be obtained; meanwhile the valve type feeding device is adopted, no devices for stirring, chopping and the like are adopted, and the quality and integrity of material particles in the feeding and drying processes when the drying machine operates are guaranteed.

Owner:HUNAN AGRICULTURAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com