Melting device for rotary blowing in waste glass recycling

A rotary and waste glass technology, which is applied in glass manufacturing equipment, glass production, glass furnace equipment, etc., can solve the problems of complicated transparent glass in glass solution, affecting processing, affecting the color of the solution, etc., and achieves the goal of ensuring high purity and pure chroma Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

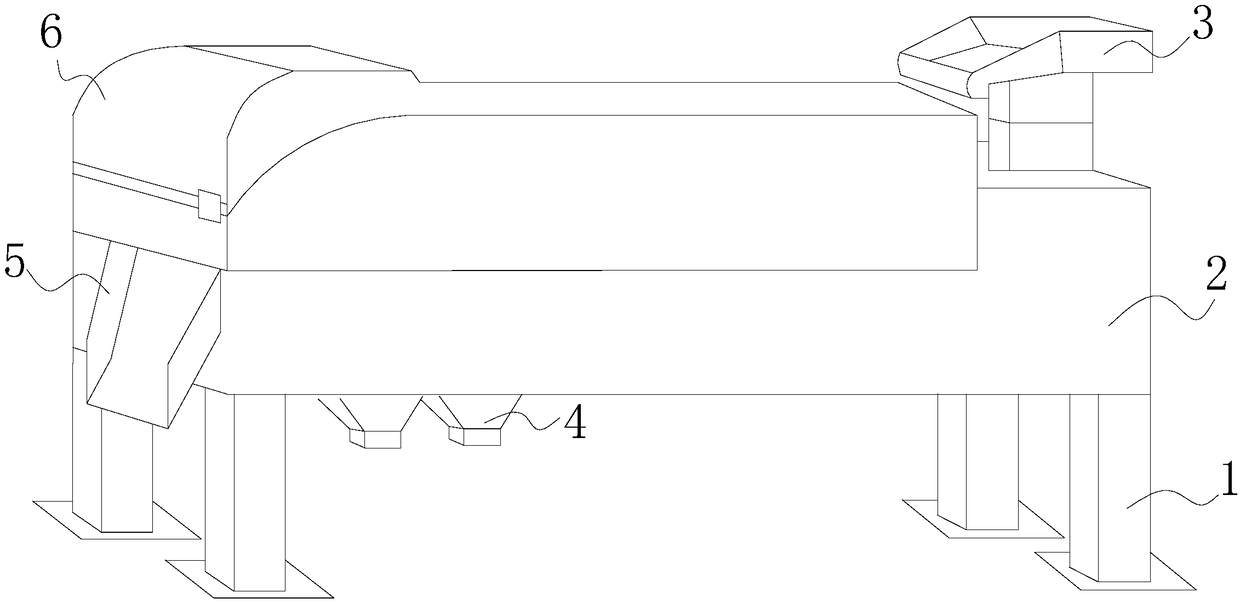

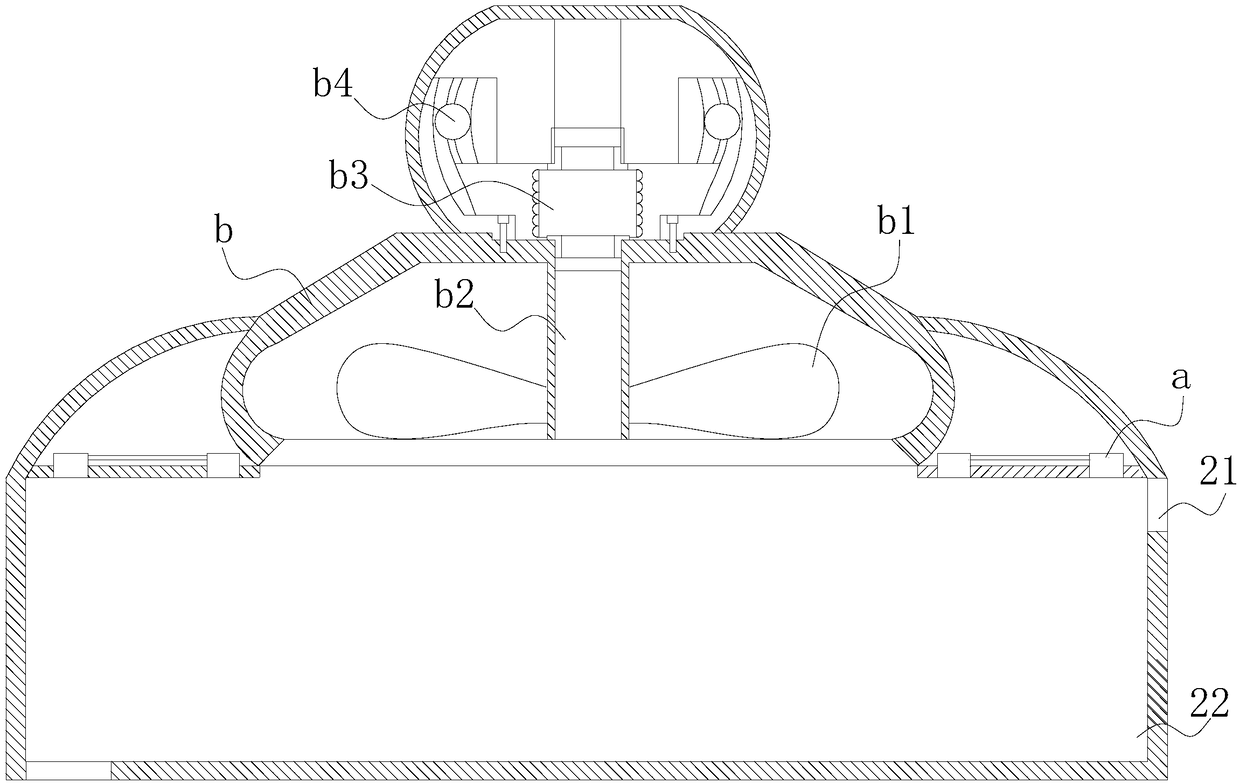

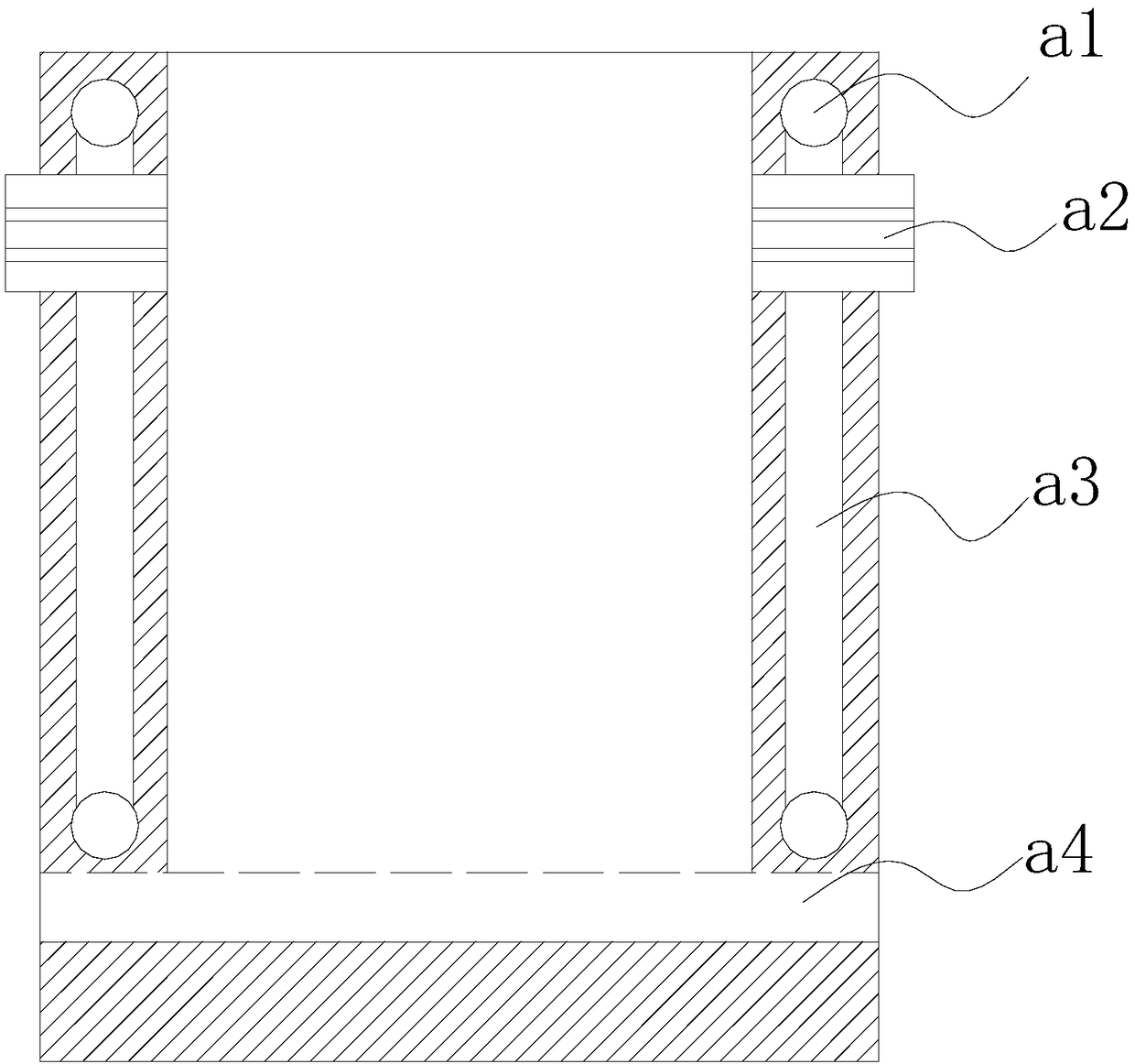

[0031] Such as Figure 1-Figure 2 As shown, the present invention provides a rotary blowing melting device for waste glass recycling. Chamber 6, the melting chamber 2 and the control chamber 6 are an integrated structure, the upper end of the melting chamber 2 is located at the right end of the control chamber 6, and a feeding tray 3 is vertically welded, and the discharge port 5 is fixed at 45° Welded on the left end of the melting chamber 2, the four supporting feet 1 are welded on the four corners of the bottom end of the melting chamber 2, the bottom end of the melting chamber 2 is close to the side of the discharge port 5 There are two slag outlets 4 with a funnel-shaped structure, and the inside of the control room 6 is composed of a pollutant adsorption device a and a gas generating device b, wherein there are two pollutant adsorption devices a, and between the two A gas generating device b is fixedly installed between them, and the gas generating device b is matched w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com