Multifunctional cereal drying equipment

A grain drying and multi-functional technology, applied in the direction of grain drying, drying, drying machine, etc., can solve the problems of not paying attention to grain quality, slow drying speed, and single function, so as to achieve fast drying speed and improve quality , Improve the effect of heat exchange speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below, the technical solution of the present invention will be described in detail through specific examples.

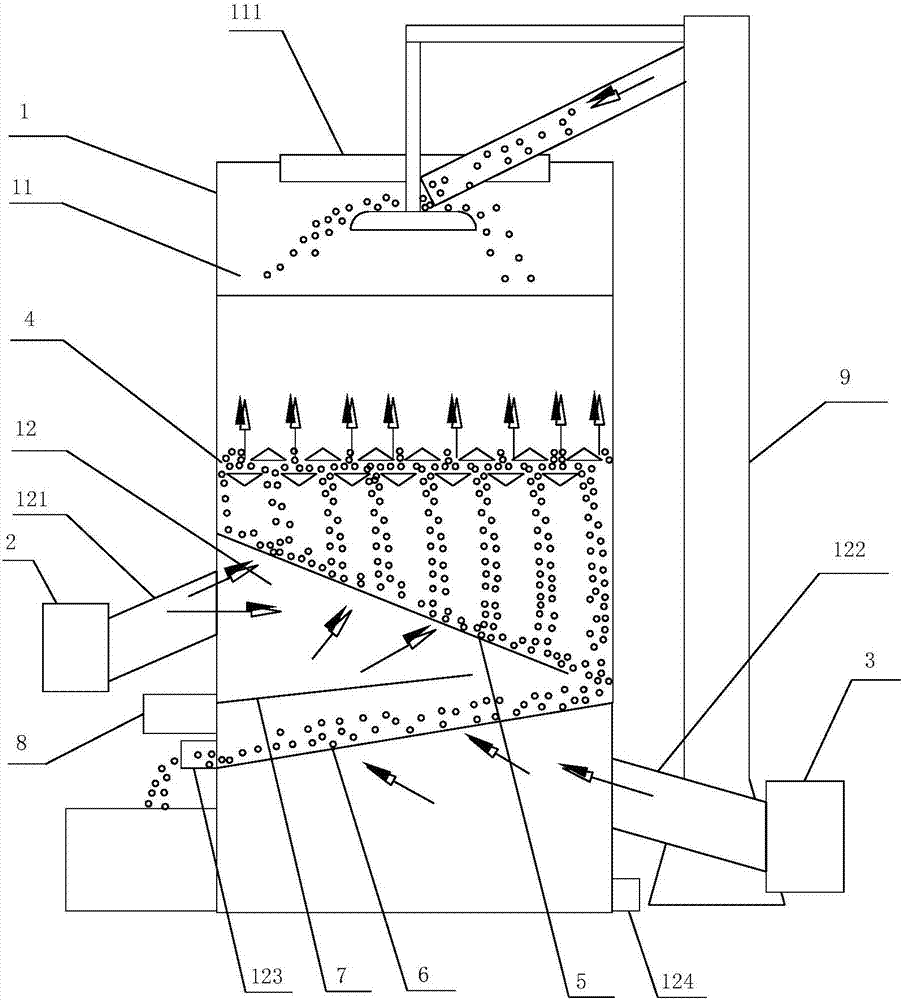

[0027] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a multifunctional grain drying equipment proposed by the present invention.

[0028] refer to figure 1 , a kind of multifunctional grain drying equipment that the embodiment of the present invention proposes, comprises; Drying box 1, first air blower 2, second air blower 3, heating device, lifting device 9, wherein:

[0029] The drying box 1 is provided with a preheating bin 11 and a drying bin 12 arranged up and down, and the preheating bin 11 is provided with an inlet 111; the grain enters the preheating bin 11 through the inlet 111, and the preheating bin 11 and the drying bin Between the dry bins 12, a plurality of strip passages 4 arranged side by side in the horizontal direction are provided; the heat of the drying bins 12 enters the preheating bin 11 from the strip pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com