High-pressure sterilization type artificial feed production process applied to industrial silkworm breeding

A high-pressure sterilization, artificial feed technology, applied in the molding or processing, application, animal feed and other directions of animal feed, can solve the problem of limiting the efficiency and scale of silkworm raising, unable to achieve factory silkworm raising, and low annual output of silkworm cocoons, etc. problems, to achieve the effect of improving feed quality, promoting impurity removal efficiency, and improving raw material purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

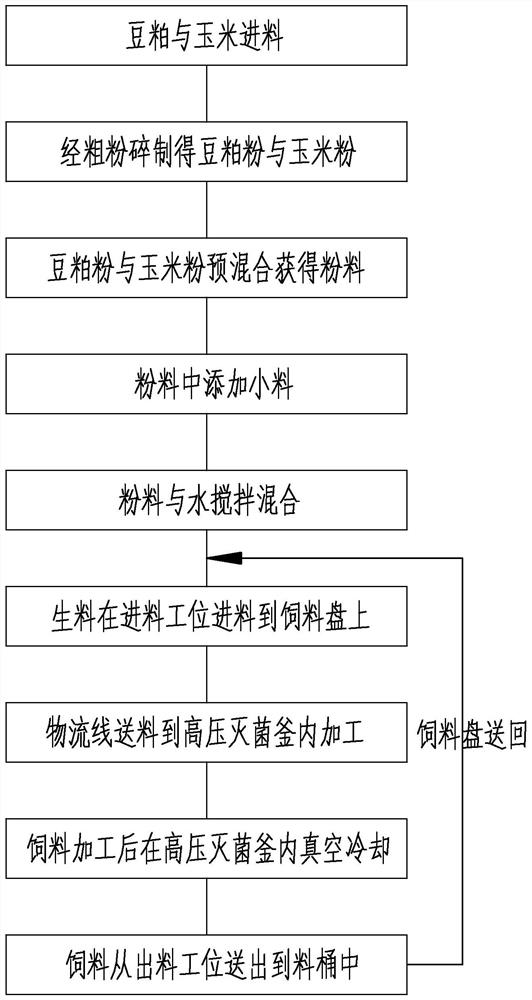

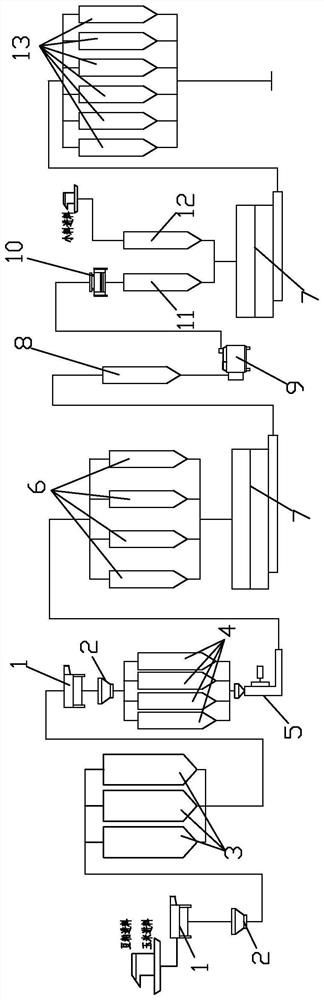

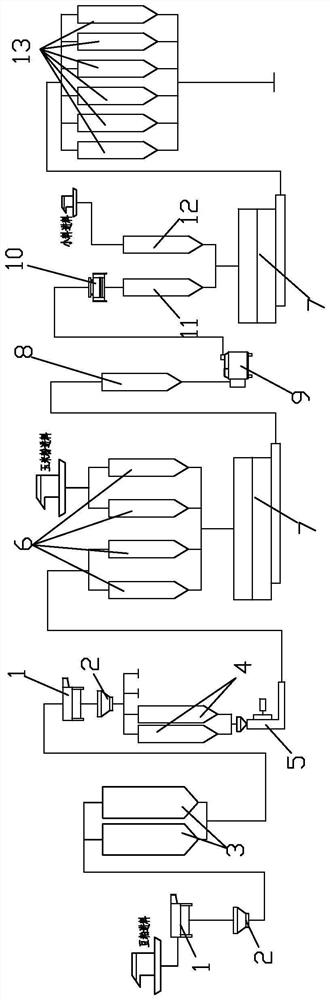

[0059] An autoclaved artificial feed production process applied to industrialized sericulture, comprising the steps of:

[0060] (1) Raw material processing: first crush the raw materials, and then mix the raw materials to obtain powder; the raw materials used include soybean meal and corn. Soybean meal is used as a protein raw material to add protein components to the feed, and corn is used as a sugar raw material to add sugar components to the feed, so that the basic components of the feed supplement the protein and sugar components needed for the growth of silkworms. The two raw materials are convenient to obtain, low in cost, high in protein content and sugar content, and meet the requirements of feed production.

[0061] Its step-by-step process includes:

[0062] 1. Raw materials entering the warehouse: the soybean meal raw material vehicle and the corn raw material vehicle are weighed separately, the weight of the whole vehicle is recorded, and then the soybean meal an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com