Method for preparing calcium hydroxide with high purity and high activity

A calcium hydroxide, high-activity technology, applied in the direction of calcium/strontium/barium oxide/hydroxide, etc., can solve the problems of difficult separation, large quantities, etc., and achieve the effect of easy removal of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

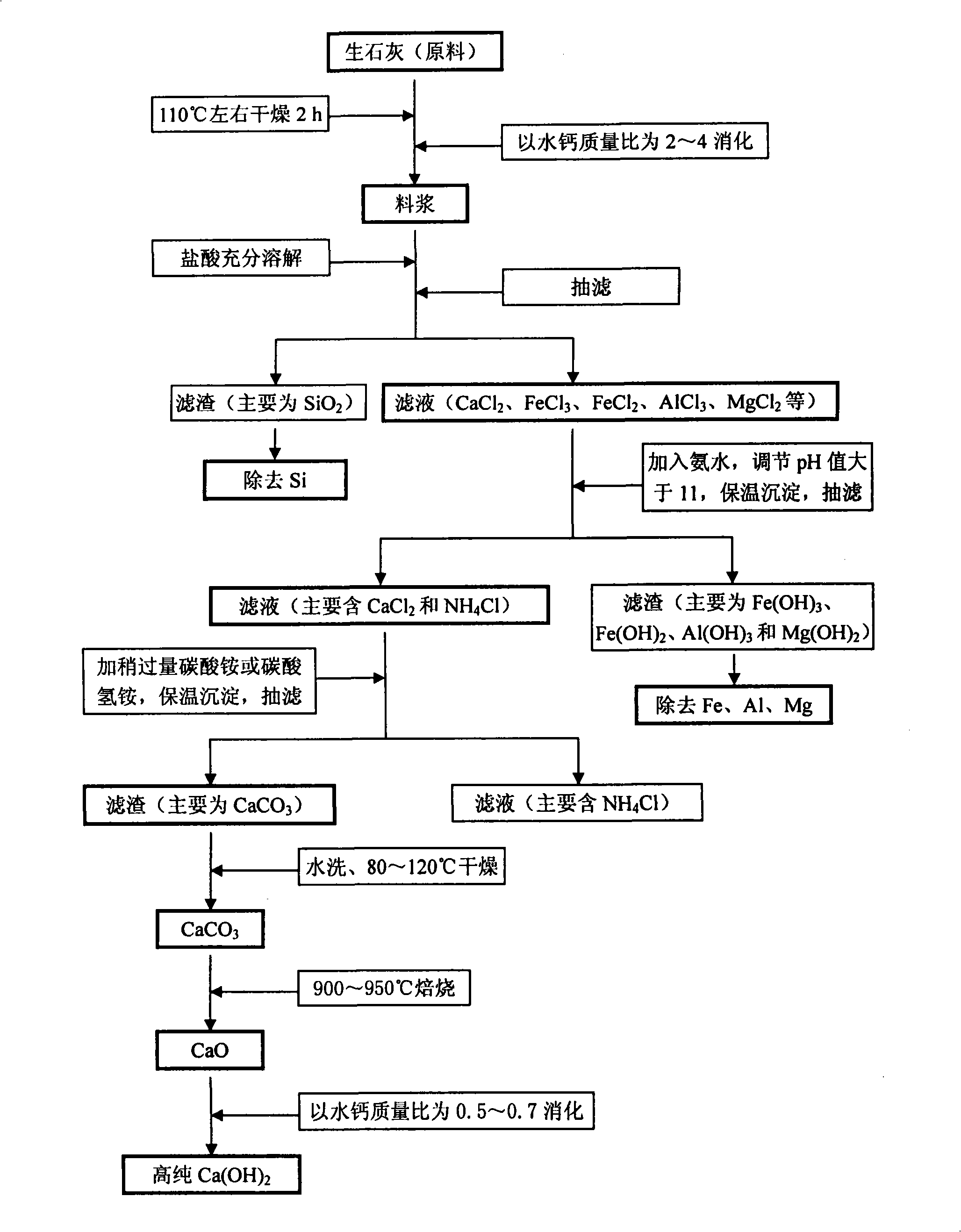

Method used

Image

Examples

Embodiment 1

[0034] Take the content of CaO as 76.42wt.%, Fe 2 O 3 The content is 1.00wt.%, Al 2 O 3 40g quicklime sample with a content of 0.12wt.% and a MgO content of 2.74wt.%, add 80ml of water and stir for digestion, continue stirring, add 200ml of hydrochloric acid with a concentration of 18wt.% to dissolve until there is no suspended matter in the solution, filter, and filter it in the filtrate Add 50ml of concentrated ammonia water (concentration of 25wt.%), the pH of the solution reaches 12.5, keep it at 80°C for 2h, filter with suction, add 260ml of 20wt.% ammonium carbonate solution to the filtrate while stirring, and keep it at 80°C. Let stand for 2h, filter by suction, and wash the calcium carbonate obtained until there is no Cl in the filtrate - It was detected, dried at 120°C and calcined at 930°C for 1 hour to obtain calcium oxide. The prepared calcium oxide is digested at a water-to-calcium mass ratio of 0.6 to obtain high-purity and high-activity calcium hydroxide.

[0035] A...

Embodiment 2

[0037] Take the same raw material as in Example 1, after stirring and digesting, dissolving in hydrochloric acid, and filtering, add 21ml of concentrated ammonia water (concentration of 25wt.%) to the filtrate, the pH of the solution reaches 11.2, and other treatment processes are the same as in Example 1, to obtain high Purity and high activity calcium hydroxide.

[0038] After testing, the obtained intermediate products and final products, in which the whiteness of calcium carbonate is 103.2, the crystal grain size is below 5μm; the CaO content in the obtained CaO product is 98.72wt.%, the content of MgO is 0.68wt.%, Fe The content of Al oxides are all outside the detection range, the yield of CaO is 99.33wt.%, and the activity is 412ml; high purity Ca(OH) after digestion 2 Its whiteness is 100.3.

Embodiment 3

[0040] Take the same raw materials as in Example 1, after stirring and digesting, dissolving in hydrochloric acid, and filtering, add 13ml of concentrated ammonia (concentration of 25wt.%) to the filtrate, and the pH of the solution will reach 10.0. The other processing procedures are the same as in Example 1, to obtain high Purity and high activity calcium hydroxide.

[0041] After testing, the obtained intermediate products and final products, in which the whiteness of calcium carbonate is 102.3, the crystal grain size is about 5μm; the CaO content in the obtained CaO product is 98.13wt.%, the content of MgO is 0.95wt.%, Fe The content of Al oxides are all outside the detection range, the yield of CaO is 99.37wt.%, and the activity is 369ml; high purity Ca(OH) after digestion 2 Its whiteness is 98.1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com