Magnesium modified chromium-based catalyst for vinyl polymerization and preparation method of magnesium modified chromium-based catalyst

A chromium-based catalyst and a technology for ethylene polymerization, which are applied in the field of magnesium-modified chromium-based catalysts for ethylene polymerization and their preparation, can solve the problems of low polymerization activity, long induction period, hydrogen-adjusted sensitivity and poor copolymerization performance, and the like. High polymerization activity, short induction period, hydrogen modulation sensitivity and good copolymerization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

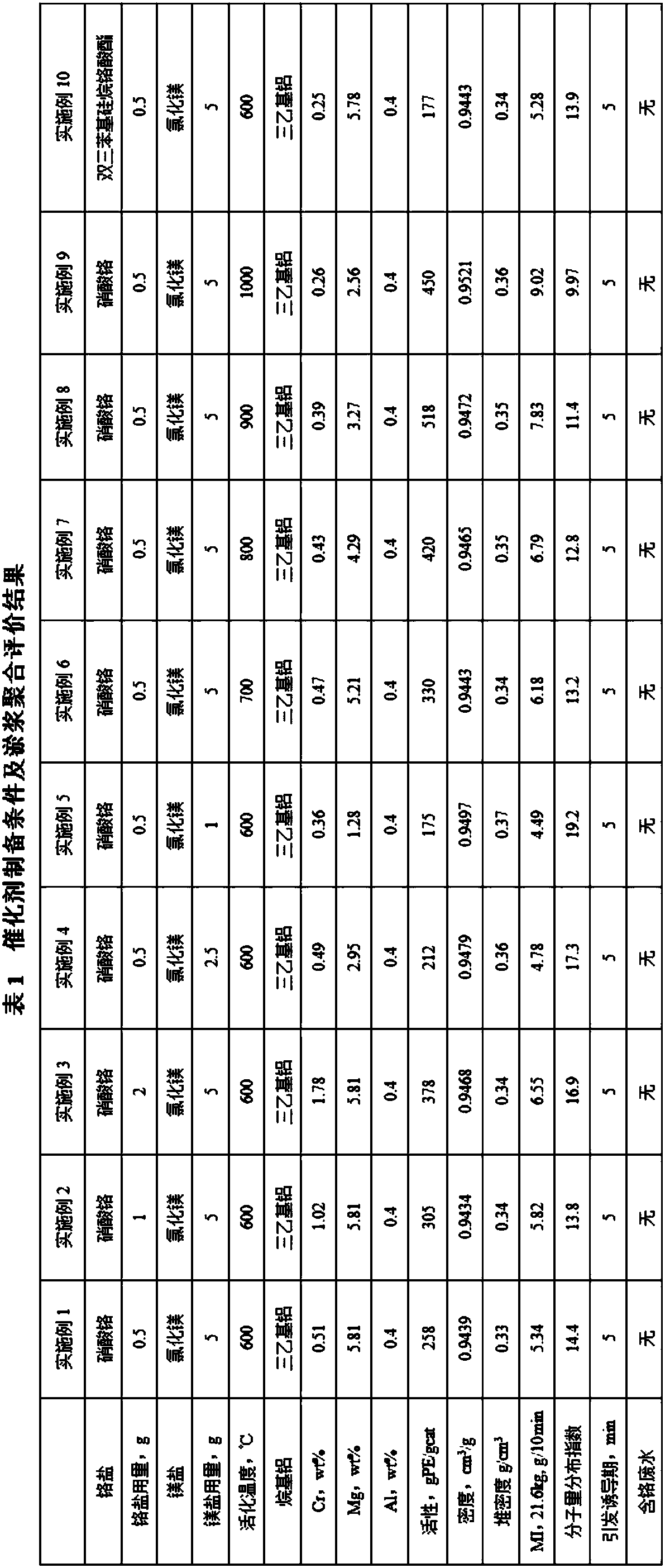

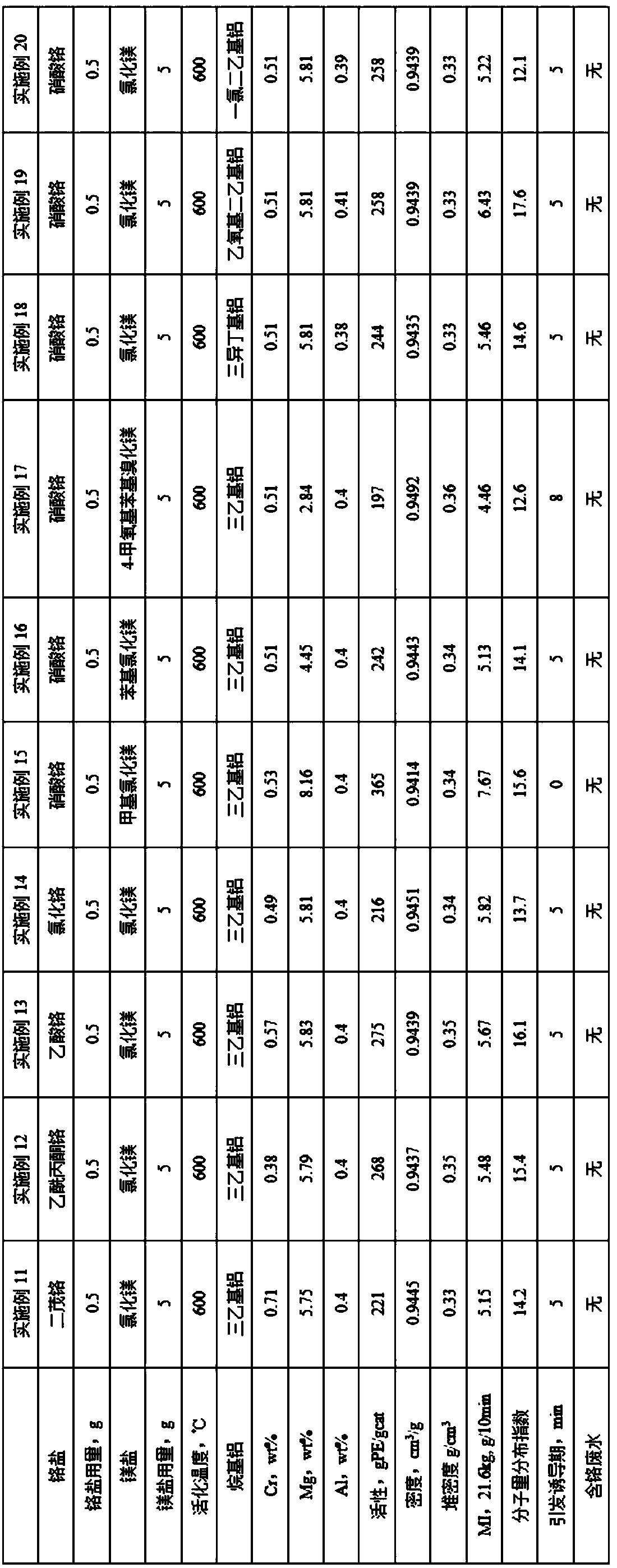

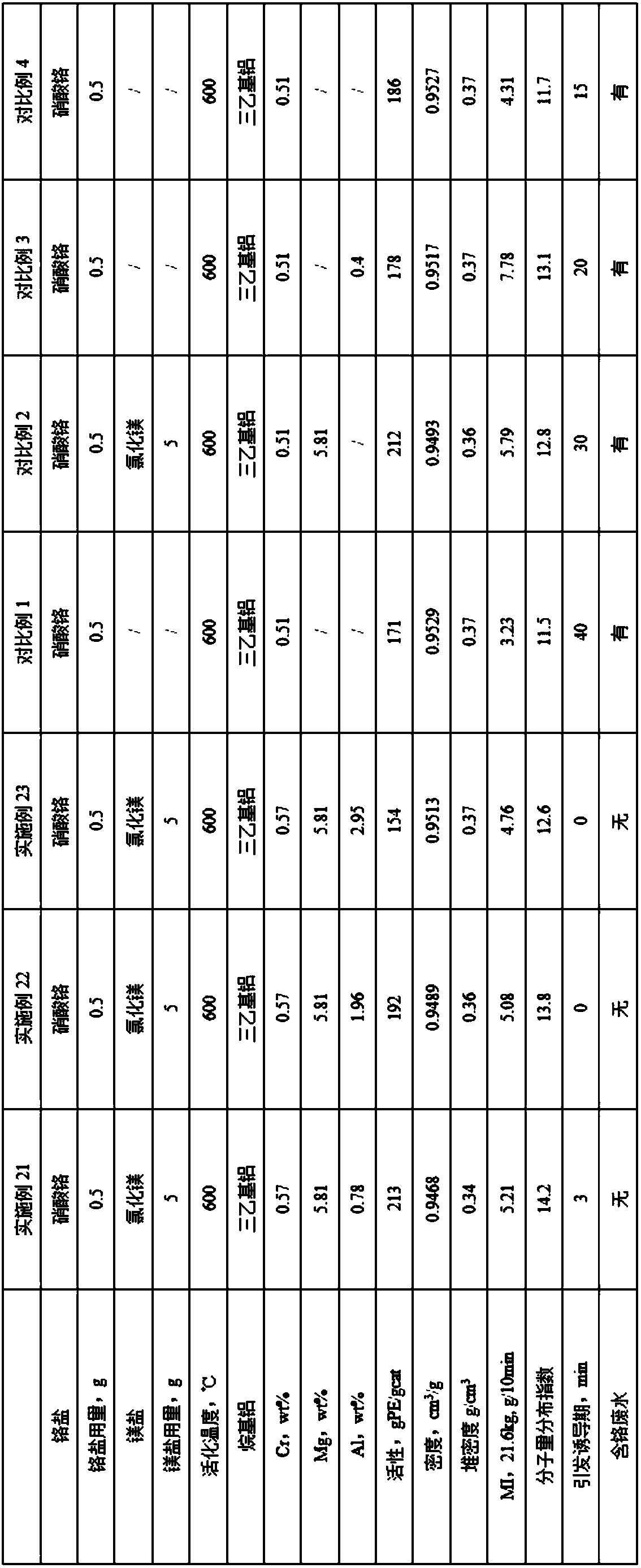

Examples

Embodiment 1

[0038] A kind of preparation method of magnesium-modified chromium series catalyst for ethylene polymerization, concrete preparation steps are as follows:

[0039] Step S1, preparation of modified carrier: add 5.0 g of magnesium chloride (MgCl2), 0.5 g of chromium nitrate and 150 mL of tetrahydrofuran into a 250 mL three-necked flask fully replaced by N2, stir and react at room temperature for 2 hours, then add 10.0 g of silica gel (WRGrace 955, The specific surface area is 240~375cm 2 / g, the pore diameter is 20~35nm, the pore volume is 1.2~1.8cm 3 / g, particle size is 20~50nm), continue to stir for 6 hours, beating is finished for standby; the mixture after stirring is spray-dried with a spray dryer, spraying conditions: inlet temperature 150°C, outlet temperature 98°C, to obtain granular Composite carrier;

[0040] Step S2, Activation: After activating the modified carrier at 600°C with dry air for 10 hours, cool to 300°C, and pass through dry nitrogen for standby;

[00...

Embodiment 2

[0046] Except that the add-on of chromium nitrate is changed into 1.0g from 0.5g, the preparation method of catalyst component is the same as embodiment 1.

Embodiment 3

[0048] Except that the add-on of chromium nitrate is changed into 2.0g from 0.5g, the preparation method of catalyst component is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com