Method for extracting phenolic substance from coal tar or direct coal liquefaction oil

A technology for directly liquefying oil and phenolic substances from coal is applied in the field of coal chemical industry, and can solve the problems of low recovery rate of phenol, high energy consumption for recovery of extractant and back-extractant, and low recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Add 67.0g of ethanolamine aqueous solution with a concentration of 60% and 40.0g of coal tar fraction oil with a distillation range of 120-340°C and a total phenol content of 47.7% into a 250ml three-necked flask with stirring, and fully stir at 60°C and normal pressure After 1 hour, 23.0 g of dephenolized oil and 83.3 g of octopamine-containing aqueous solution were obtained after liquid separation. Put the octopamine-containing aqueous solution into a 150ml flask, and pass through industrial CO at 60°C and normal pressure 2 The gas was acidified, cooled after 1h, and separated to obtain 19.9g of crude phenol oil and 71.6g of CO rich 2 ethanolamine in water; will be enriched with CO 2 The organic amine aqueous solution was placed in a flask and heated to 80°C for desorption, and stirred at normal pressure for 1 hour to obtain 64.9 g of regenerated ethanolamine aqueous solution. All contain a small amount of ethanolamine and water in the dephenolized oil and crude phe...

Embodiment 2~7

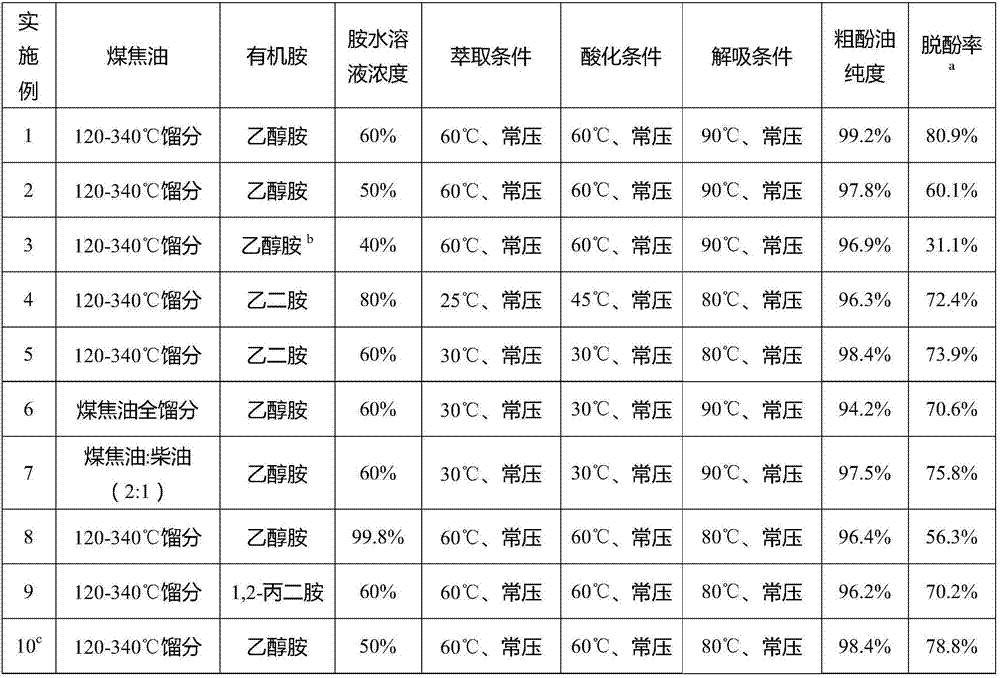

[0065] Embodiments 2-7: The device, method and steps are the same as in Embodiment 1, and other implementation conditions and results are listed in Table 1.

Embodiment 8

[0066] Embodiment 8: device, method and step are identical with embodiment 1, but make extraction agent with pure ethanolamine, add water and dissolve into 50% aqueous solution in extraction phase, again with industrial CO 2 The gas is used to acidify it, and other implementation conditions and results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com