Method for preparing hydroxylamine or hydroxylamine salt from ketone, ammonia and hydrogen peroxide

A hydrogen peroxide and hydroxylamine salt technology, applied in the direction of hydroxylamine, nitrogen and non-metallic compounds, etc., can solve the problems of high energy consumption, low conversion rate of ketoxime equilibrium, complex process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

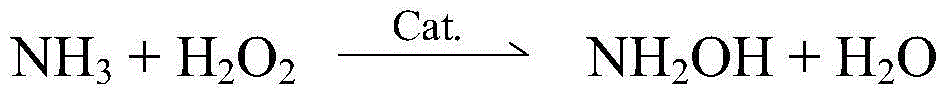

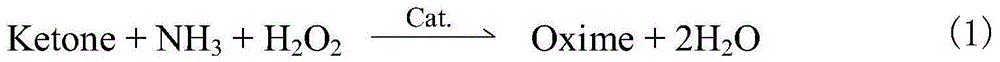

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] Example 1: Cyclohexanone-cyclohexane solution, hydrogen peroxide, and circulating water containing titanium-silicon molecular sieves were respectively continuously added to a 1000ml reactor equipped with a mechanical stirring and condensing reflux device through a double plunger micropump. The flow meter is added continuously; the concentration of hydrogen peroxide is 27.5%, the flow rate is 68.0g / h, the mass concentration of cyclohexanone solution is 37.5%, the flow rate is 130.8g / h, the flow rate of circulating water is 285.6g / h, and the flow rate of ammonia gas is 18.7g / h; The temperature is 69°C, and the pressure is maintained at normal pressure; the product overflows out of the reactor, and after separation by decantation, the catalyst is reused with the water phase, and the cyclohexane solution containing cyclohexanone oxime is sent to the storage tank for standby, and is determined by gas chromatography. It is sent into the countercurrent hydrolysis-centrifugal ex...

Embodiment 2

[0091] Embodiment 2: Reaction steps such as embodiment 1, the difference is that the ketoxime in the reaction is butanone oxime. Among them, the conversion rate of butanone oxime is 61.8%, and the selectivity of hydroxylamine sulfate is 99.5%.

Embodiment 3

[0092] Embodiment 3: The reaction steps are as in embodiment 1, the difference is that the inorganic acid in the reaction is hydrochloric acid. The conversion rate of cyclohexanone oxime was 57.2%, and the selectivity of hydroxylamine hydrochloride was 98.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com