Automatic control method of butadiene polymerization

A technology of polymerization reaction and butadiene, which is applied in the direction of non-electric variable control, control/regulation system, and simultaneous control of multiple variables to achieve the effects of improving stability, reducing energy consumption and material consumption, and avoiding detonation and supercooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

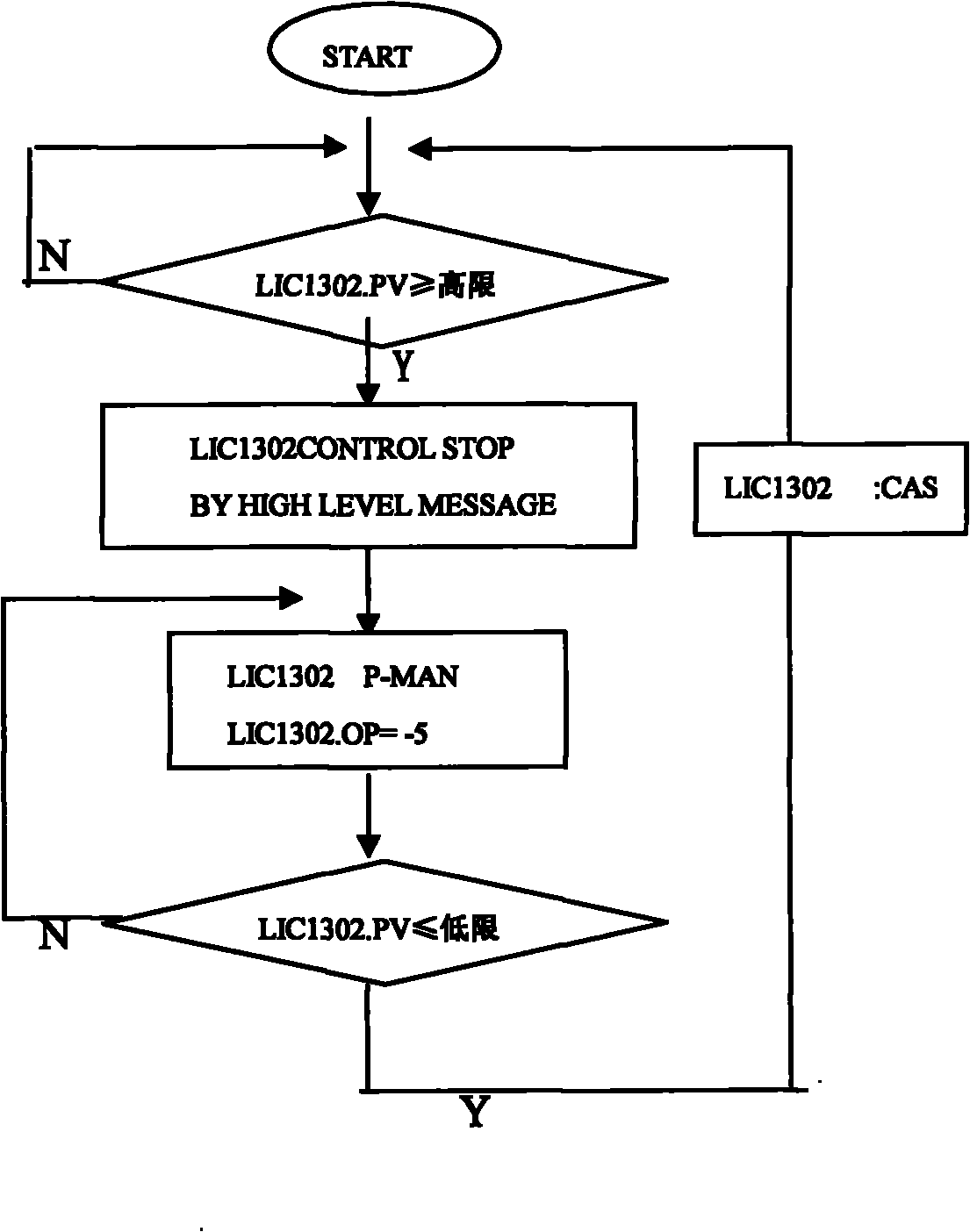

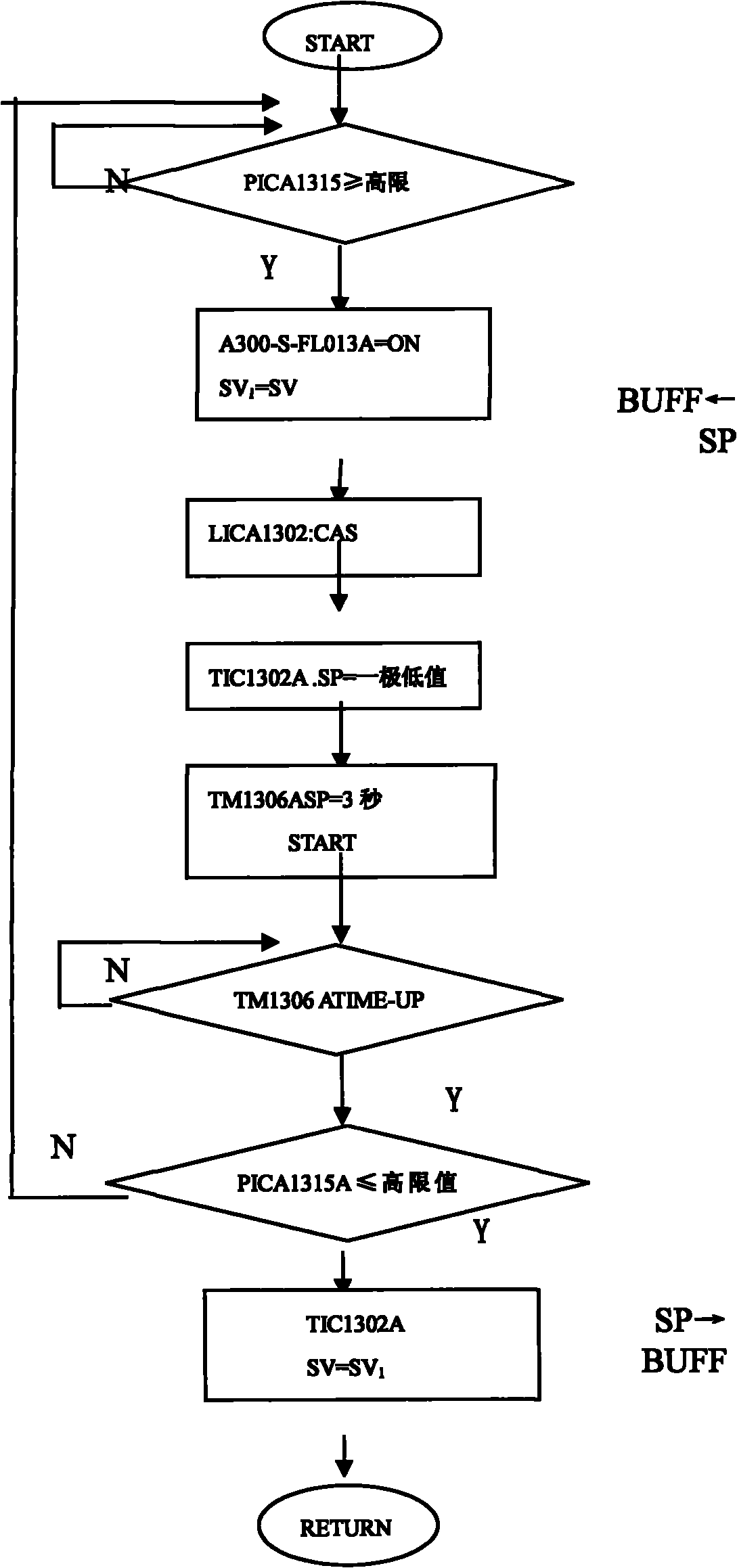

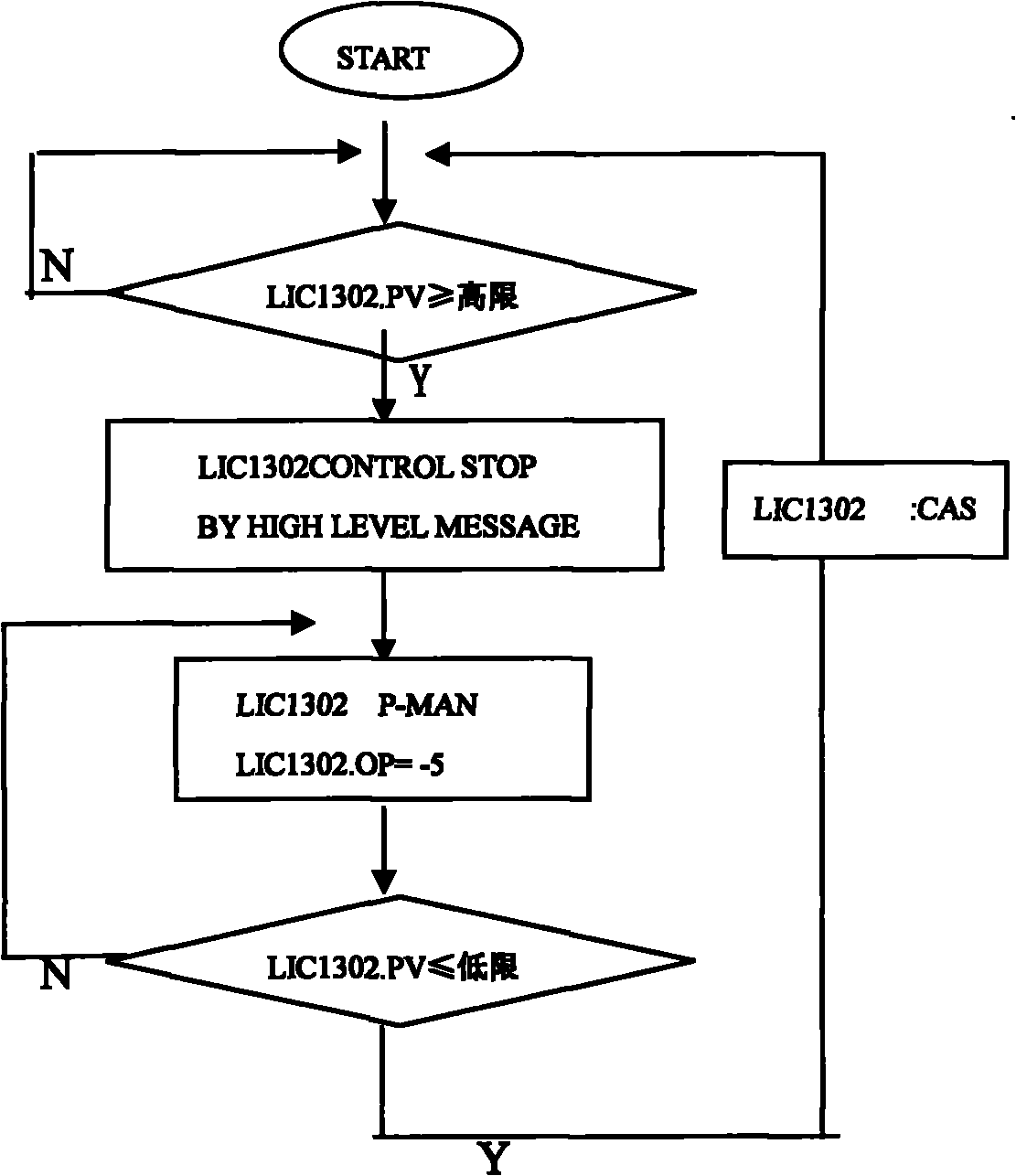

[0012] In the specific implementation process, four situations are explained from the temperature-liquid level cascade adjustment, the specific control of temperature rise and pressure increase, the control of the ammonia liquid level in the reactor jacket, and the control process when the reactor pressure is super high:

[0013] (1) Temperature-liquid level cascade adjustment

[0014] During the reaction, the program will select the liquid level regulator as the program cascade adjustment or program manual adjustment according to the ammonia liquid level in the jacket. According to the temperature of the reactor and the situation of the ammonia position, the following processes are divided:

[0015] 1) When the temperature in the reactor changes

[0016] a) The temperature in the reactor changes, and the measured value of the temperature changes;

[0017] b) The output of temperature changes, and the given value of ammonia liquid level changes (the output of temperature is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com