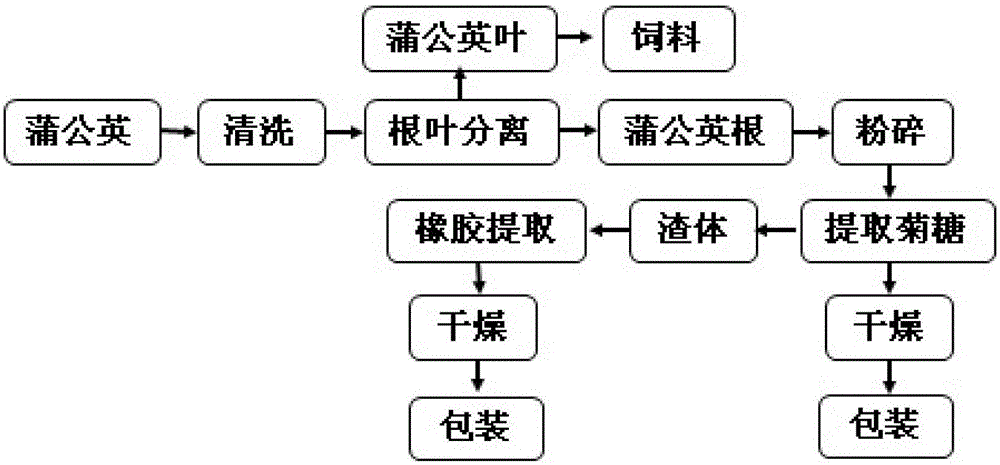

A method for continuously and efficiently extracting dandelion rubber and inulin from dandelion rubber grass

A dandelion rubber and cyclic extraction technology is applied in the field of continuous and efficient cyclic extraction of dandelion rubber and inulin from dandelion rubber grass, which can solve the problems of low resource utilization efficiency, high energy consumption and material consumption, single product, etc., and achieve a rich process product line. , the effect of reducing energy consumption and material consumption and improving resource utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] After cleaning the dandelion rubber grass, separate the leaves and roots, weigh 100g of dandelion wet root (moisture content ≈ 40%), and crush it to a sheet-like adhesion body with a thickness of 0.5mm and a diameter of about 2mm. Then, according to the weight ratio of water and dandelion wet root of 6:1, put the crushed dandelion wet root into the extraction reaction kettle, add 600ml of distilled water, and extract at the boiling point. The extract is light yellow semi-finished inulin , the extract was treated by conventional processes such as decolorization, and then spray-dried to obtain 10 g of white finished inulin.

[0022] In order to improve the extraction rate, the extraction preferably adopts 6 stages of countercurrent extraction process, and the extraction time of each stage is 15 minutes. According to the above process to extract inulin, 10g of inulin can be extracted from every 100g of dandelion wet root (moisture content ≈ 40%). Based on the inulin conte...

Embodiment 2

[0024] Dry the inulin dregs obtained after extraction in Example 1 (45g, moisture content 8%), and then put the dried inulin dregs into the extraction reaction kettle according to the weight ratio of the solvent to the inulin dregs of 6:1 And add 310ml of toluene, extract at 40°C, inject the extract into the steam tank for steam distillation to recover the solvent, the steam pressure is 350ka, and dandelion rubber is precipitated at the same time, and floats on the water surface, open the valve below the steam tank, rubber and water Get rid of together, obtain 3g dandelion rubber through drying and weighing. The final slag is dried and weighed to be 38g (moisture content <10%)

[0025] In order to improve the extraction rate, the extraction adopts a 6-section countercurrent extraction process, and the extraction time of each section is 15 minutes. According to the above process to extract dandelion rubber, 3g of dandelion rubber can be obtained per 100g of dandelion wet root ...

Embodiment 3

[0027] After cleaning the dandelion rubber grass, separate the leaves and roots, weigh 100g of dandelion wet root (water content ≈ 60%), and crush it to a sheet-like adhesion body with a thickness of 0.5mm and a diameter of about 5mm. Then according to the weight ratio of water and dandelion wet root being 10:1, put the crushed dandelion wet root into the extraction reaction kettle, add 1000ml of distilled water to extract, the extract is light yellow semi-finished inulin, and The extract was treated by conventional processes such as decolorization, and then spray-dried to obtain 12 g of white finished inulin.

[0028] In order to improve the extraction rate, the extraction preferably adopts a 7-stage countercurrent extraction process, and the extraction time of each stage is 30 minutes. According to the above process to extract inulin, 12g of inulin can be extracted per 100g of dandelion wet root (water content ≈60%). Based on the inulin content of 40wt% (dry root weight), t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com