Hydraulic sliding sleeve

A hydraulic sliding sleeve and hydraulic technology, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of limited number of fracturing stages, limited displacement, packer can not guarantee complete sealing, etc. Achieve the effect of increasing fracturing scale, improving reliability and realizing selective production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

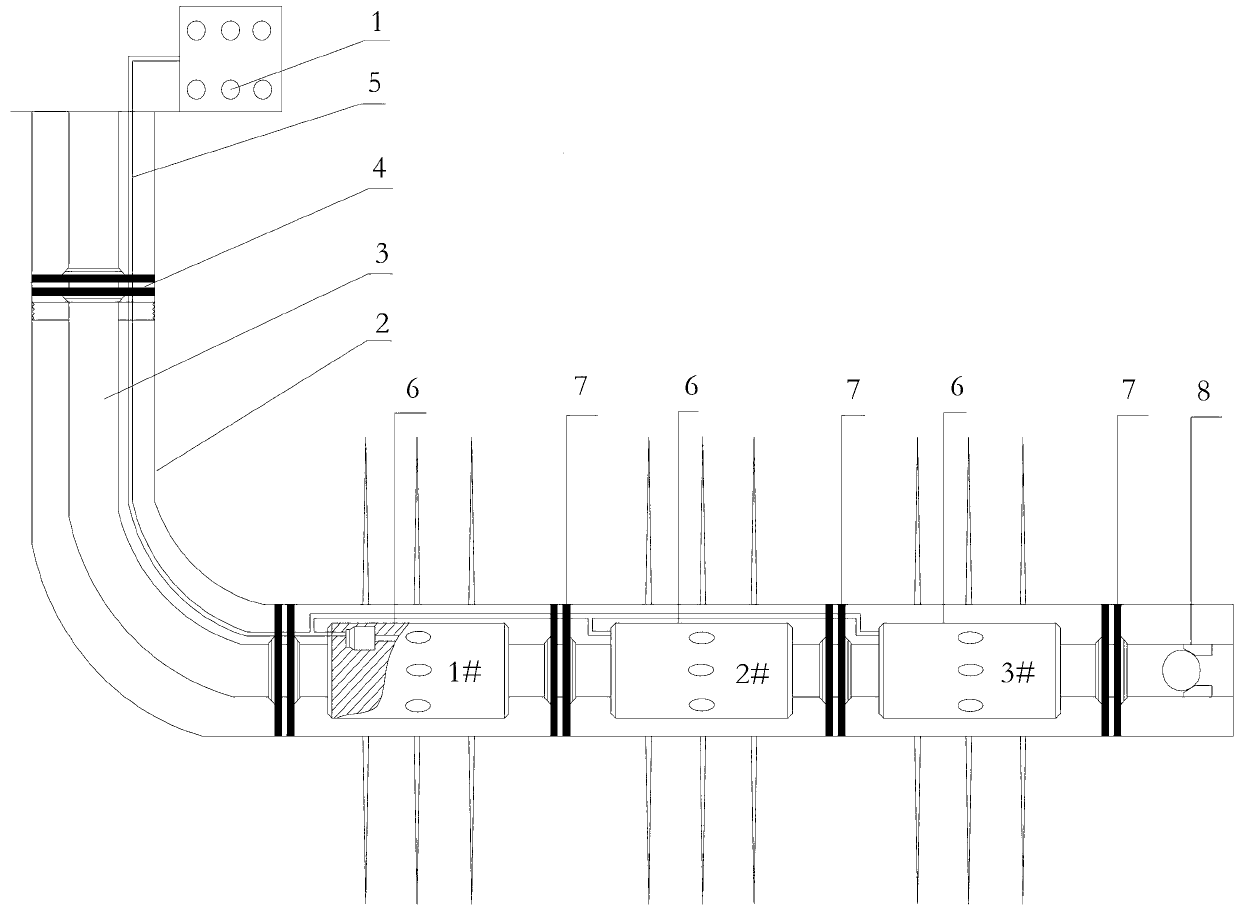

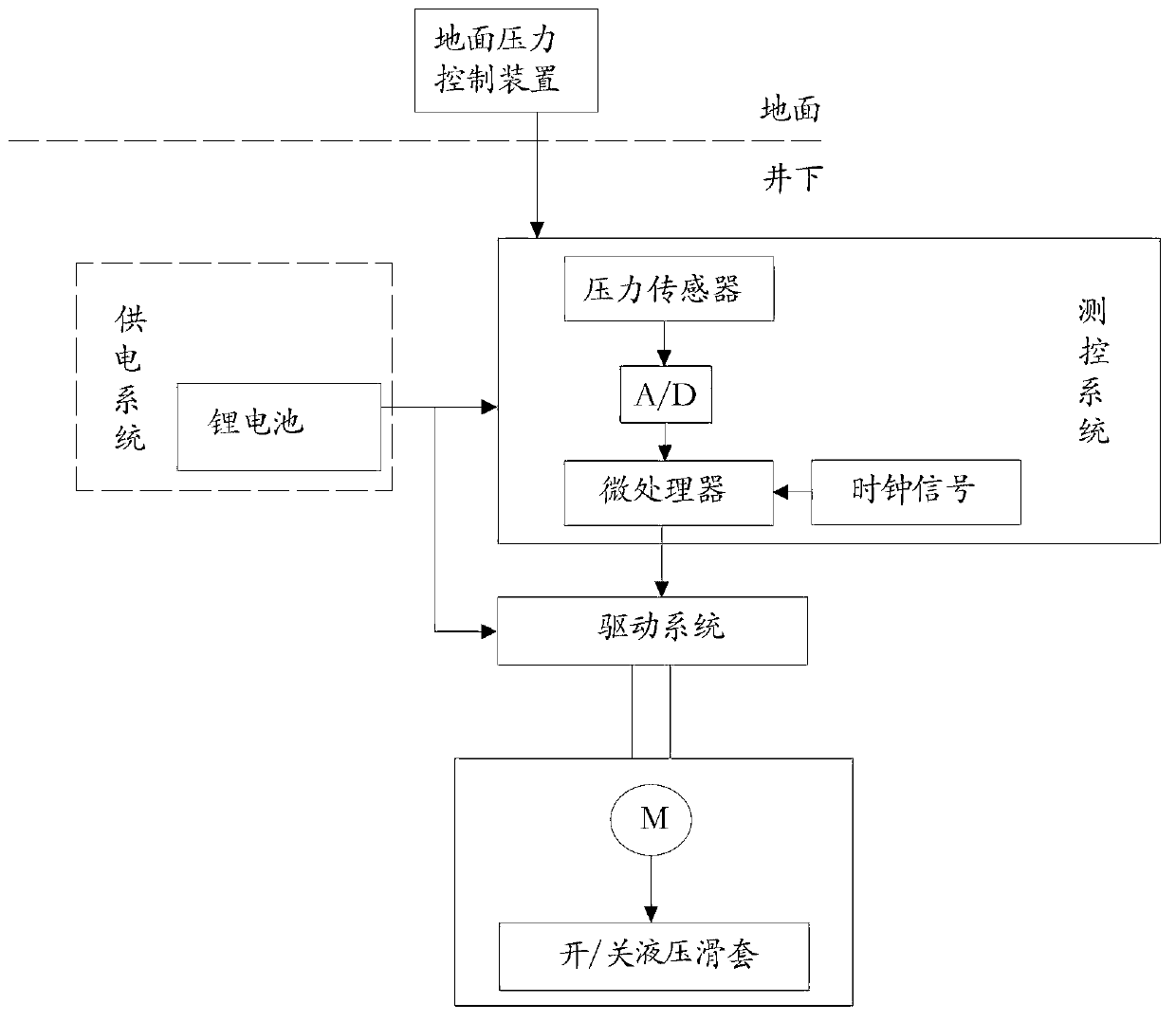

[0038] as attached figure 1 As shown, the completion string of the embodiment of the present invention includes a surface hydraulic control device, a casing 2, an oil pipe 3 arranged inside the casing 2, a hydraulic pipeline 5, and a tieback hanger 4, which are sequentially connected with the oil pipe 3 in the horizontal section Multiple fracturing construction units and the sealing unit at the bottom of the pipe string;

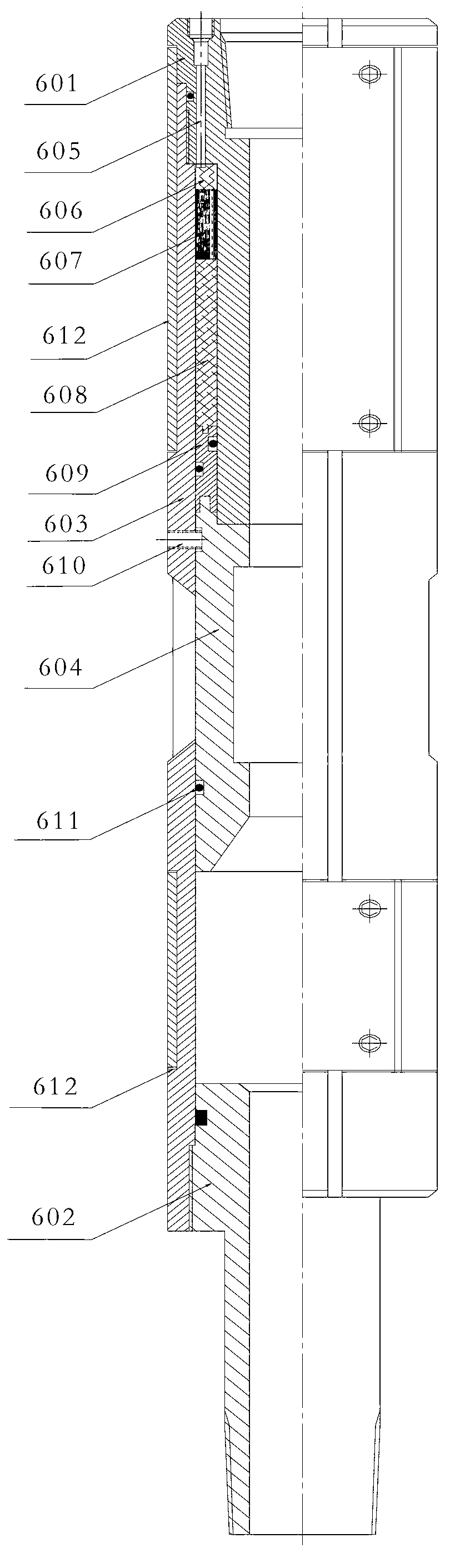

[0039] The fracturing construction unit is sequentially provided with a hydraulic packer 7 and a hydraulic sliding sleeve 6; the bottom end seating unit of the pipe string is sequentially provided with a hydraulic packer 7 and a ball seat 8 connected to the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com