Method for production of high-purity m-cresol

A technology for the production of m-cresol and m-cresol, applied in chemical instruments and methods, ion exchange regeneration, preparation of organic compounds, etc., can solve problems such as low quality m-cresol products and complicated process flow, and achieve good economic benefits, Simple production process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

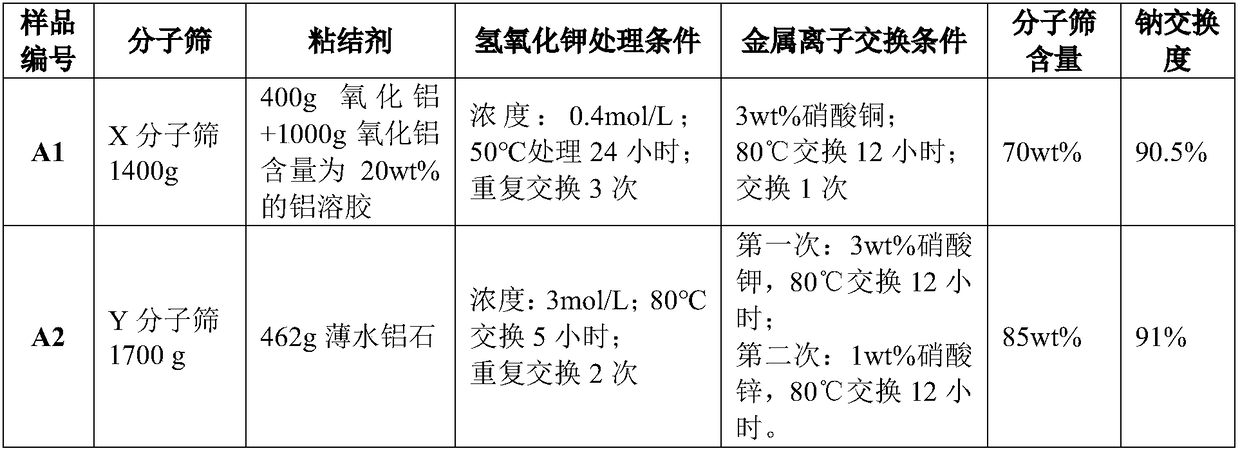

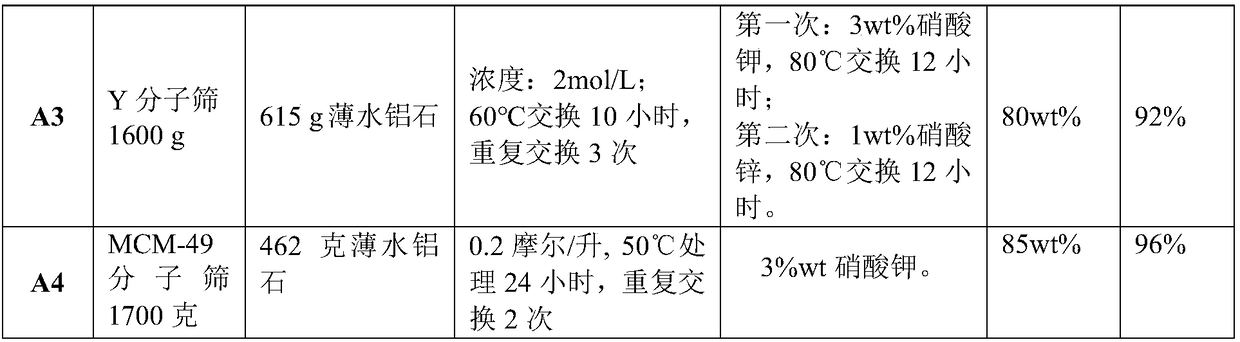

[0061] The preparation of embodiment 1 molecular sieve adsorbent sample

[0062] Mix the molecular sieve and the binder in a certain proportion, add an appropriate amount of 5% dilute nitric acid as an auxiliary agent, extrude into a strip, dry at 120°C, and bake at 550°C for 10 hours to obtain a shaped sample. Cut the above molded sample into 1-2 mm to obtain a columnar matrix. Add 1,500 grams of the parent body into 5,000 mL of potassium hydroxide solution, treat at a certain temperature for a period of time and a certain number of times, and then wash with deionized water until neutral. Dry at 120°C and bake at 500°C for 10 hours to prepare potassium hydroxide modified samples. Add 1500 grams of potassium hydroxide modified sample into 5000 mL of metal nitrate aqueous solution containing a certain concentration for ion exchange modification, treat it at a certain temperature for a period of time and a certain number of times, and wash it with deionized water until neutral....

Embodiment 2

[0068] The preparation of embodiment 2 isomerization catalyst samples

[0069] Mix the molecular sieve and the binder in a certain proportion, add an appropriate amount of 5% dilute nitric acid as an auxiliary agent, extrude into a strip, dry at 120°C, and bake at 550°C for 10 hours to obtain a shaped sample. The above-mentioned molded sample is cut into 1-3 mm to prepare a columnar matrix. A certain amount of columnar matrix is placed in a certain amount of metal solution for ion exchange modification, then dried at 120°C and calcined at 600°C for 3 hours to obtain an isomerization catalyst.

[0070] The serial number of the obtained product, the added amount of molecular sieve and binder, the concentration of the solution used for ion exchange, the content of molecular sieve and the content of metal oxide in the isomerization catalyst are shown in Table 2.

[0071] Table 2

[0072]

Embodiment 3~12

[0073] The production of embodiment 3~12 m-cresols

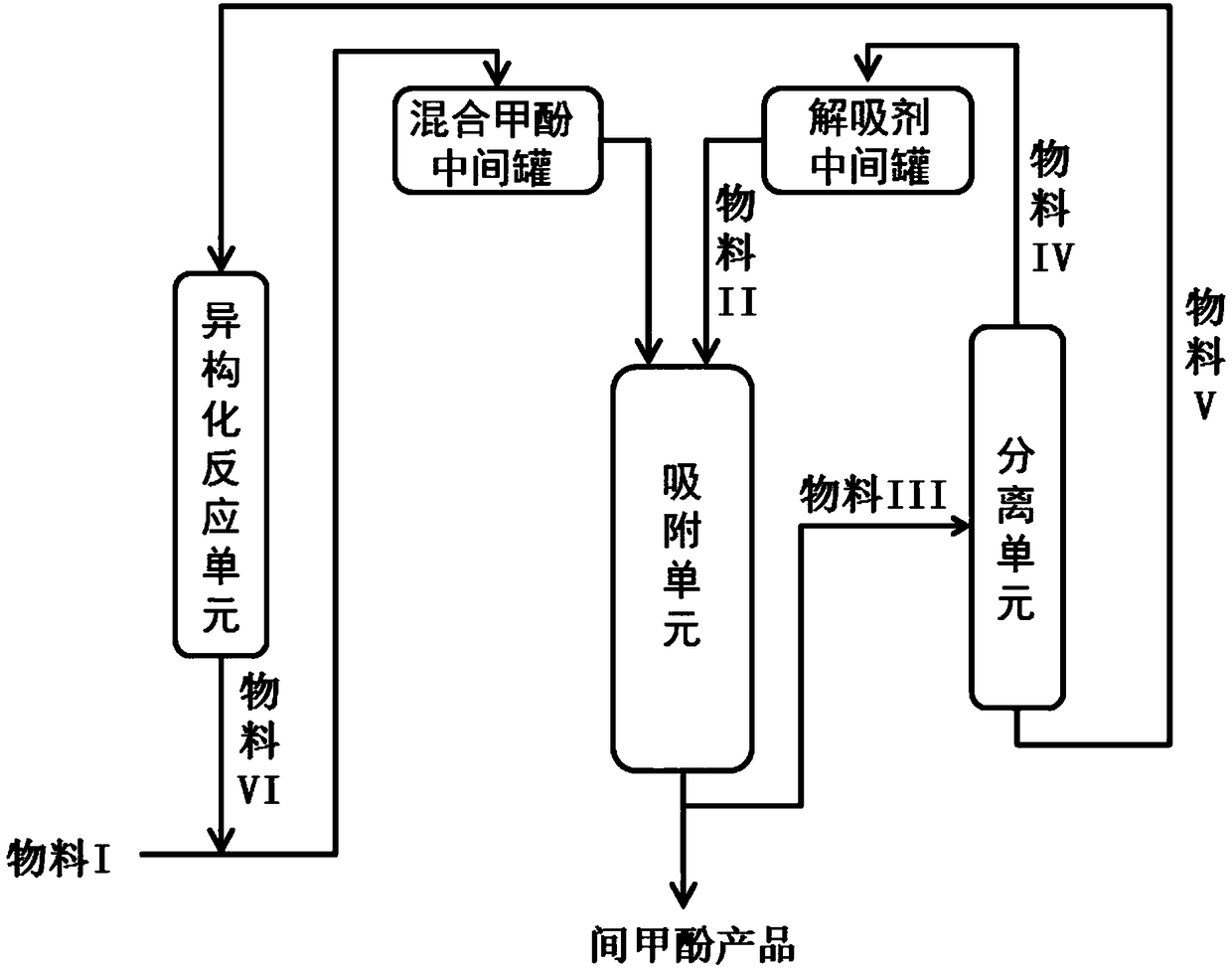

[0074] Using the molecular sieve adsorbent sample in embodiment 1 and the isomerization catalyst sample in embodiment 2, according to the attached figure 1 The flow diagram is shown for the production of m-cresol. Among them, the isomerization reaction is carried out on a fixed bed reaction device; the weight space velocity is 0.5 to 5 hours -1 , The reaction temperature is 320-450°C, and the diluent gas is water vapor.

[0075] In Examples 3 to 12, the conditions of the adsorption unit, the conditions of the isomerization reaction unit, and the reaction results in each example are shown in Table 3. In Examples 3-12, the purity of the obtained m-cresol products is greater than 99.5%.

[0076] table 3

[0077]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com