Wet bonding resistant alcohol soluble self-bonded paint and preparation method thereof

A self-adhesive paint and alcohol-soluble technology, which is applied in coatings, epoxy resin coatings, polyamide coatings, etc., can solve the problems of short storage period, narrow production process, and unstable quality of enameled wire products, and achieve good homogeneity and Storage stability, good anti-wet stickiness, long use and storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

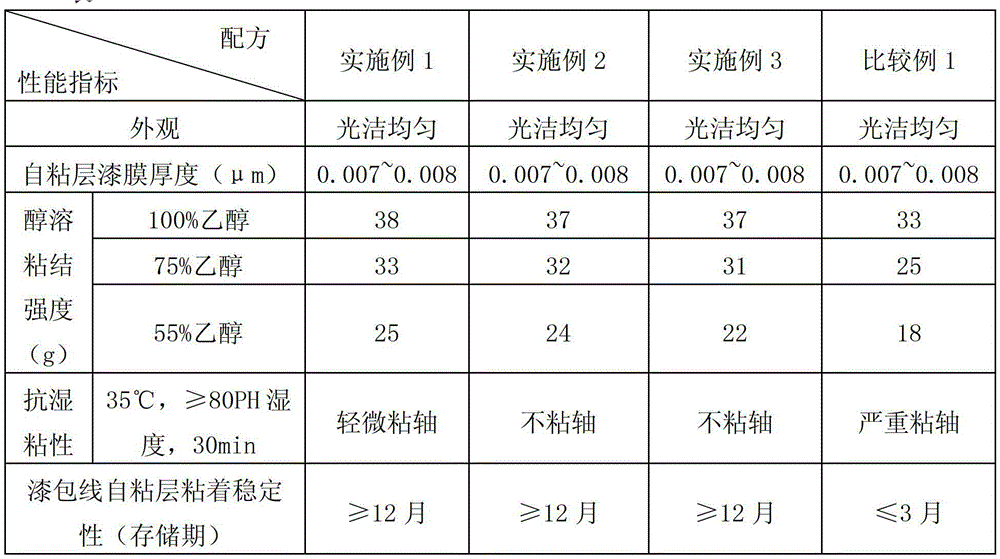

Examples

Embodiment 1

[0019] An alcohol-soluble self-adhesive paint that resists moisture sticking, the composition is as follows by weight: 35 parts of m-p-cresol, 48 parts of xylene, 5 parts of butanol, 4.9 parts of ES-08 alcohol-soluble nylon, 4.9 parts of IC Soluble nylon, 1.2 parts of 607 epoxy resin, 1.2 parts of 604 epoxy resin, 0.12 parts of oleic acid amide.

[0020] The preparation method of the alcohol-soluble self-adhesive paint of anti-humidity sticking, its step comprises as follows:

[0021] (1) According to the weight ratio, add 35 parts of m-p-cresol, 48 parts of xylene, and 5 parts of butanol into the reaction kettle with a stirrer, stir and mix evenly, and turn on the heating to 45-50°C, and gradually add 4.9 parts ES-08 alcohol-soluble nylon, 4.9 parts of IC alcohol-soluble nylon, stirring at the same time to raise the temperature to 90-100°C, keep it warm for 2.5h, until ES-08 alcohol-soluble nylon and IC alcohol-soluble nylon are completely dissolved, then cool down to 50-60°C...

Embodiment 2

[0026] An alcohol-soluble self-adhesive paint with anti-moisture sticking, the composition is as follows in parts by weight: 39 parts of m-p-cresol, 41 parts of xylene, 7 parts of butanol, 4.6 parts of ES-08 alcohol-soluble nylon, 4.6 parts of IC alcohol Soluble nylon, 1.5 parts of 607 epoxy resin, 1.5 parts of 604 epoxy resin, 0.13 parts of oleic acid amide.

[0027] The preparation method of the alcohol-soluble self-adhesive paint of anti-humidity sticking, its step comprises as follows:

[0028] (1) According to the weight ratio, add 39 parts of m-p-cresol, 41 parts of xylene, and 7 parts of butanol into the reaction kettle with a stirrer, stir and mix evenly, and turn on the heating to 45-50°C, and gradually add 4.6 parts ES-08 alcohol-soluble nylon, 4.6 parts of IC alcohol-soluble nylon, stirring at the same time to raise the temperature to 90-100°C, keep it warm for 3 hours until ES-08 alcohol-soluble nylon and IC alcohol-soluble nylon are completely dissolved, then cool...

Embodiment 3

[0033] An anti-moisture-sticking alcohol-soluble self-adhesive paint, the composition is as follows in parts by weight: 44 parts of m-p-cresol, 35 parts of xylene, 9 parts of butanol, 4.4 parts of ES-08 alcohol-soluble nylon, 4.4 parts of IC alcohol Soluble nylon, 1.8 parts of 607 epoxy resin, 1.8 parts of 604 epoxy resin, 0.15 parts of oleic acid amide.

[0034] The preparation method of the alcohol-soluble self-adhesive paint of anti-humidity sticking, its step comprises as follows:

[0035] (1) According to the weight ratio, add 44 parts of m-p-cresol, 35 parts of xylene, and 9 parts of butanol into the reactor with a stirrer, stir and mix evenly, and turn on the heating to 45-50 ° C, gradually add 4.4 parts ES-08 alcohol-soluble nylon, 4.4 parts of IC alcohol-soluble nylon, stirring at the same time to raise the temperature to 90-100 ° C, keep warm for 3 hours until ES-08 alcohol-soluble nylon and IC alcohol-soluble nylon are completely dissolved, then lower the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com