Method for producing methyl phenol

A technology of cresol and molecular sieve, which is applied in the field of cresol production, can solve problems such as waste water and equipment corrosion, reduce the temperature difference between inlet and outlet, ensure the safety and reliability of the process, and avoid by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

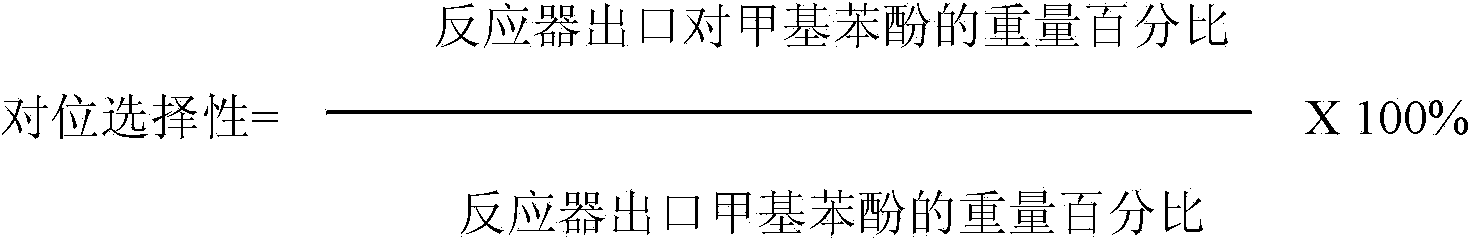

Image

Examples

Embodiment 1

[0037] The preparation process of the molecular sieve catalyst is as follows: 170 grams of hydrogen-type MCM-22 molecular sieves with a molar silicon-aluminum ratio of 30 are mixed with 100 grams of silicon dioxide weight 30% silica sol, a certain amount of calcium acetate is added to mix evenly, and an appropriate amount of 10% Dilute nitric acid is used as extrusion aid to extrude into strips. Dry at 120°C and bake at 550°C for 4 hours. The above catalyst was cut into 1-3 mm to prepare columnar catalyst matrix A0. 20 grams of matrix catalyst A0 was added to 50 ml of nitric acid solution with a weight content of 10%, and soaked at room temperature for 12 hours. Dry at 120°C and bake at 500°C for 2 hours to prepare A1. Molecular sieve catalyst A was obtained by steaming 20 grams of Al in a 100% steam atmosphere for 10 hours at a temperature of 350° C. and roasting at 550° C. for 3 hours. The weight content of molecular sieve in the prepared catalyst is 85%, and the weight co...

Embodiment 2

[0039] The preparation process of the molecular sieve catalyst is as follows: 170 grams of hydrogen-type MCM-49 molecular sieves with a molar silicon-aluminum ratio of 28 are mixed with 100 grams of silicon dioxide weight 30% silica sol, a certain amount of barium calcium nitrate is added to mix evenly, and an appropriate amount of 10 % dilute nitric acid as extrusion aid, extrusion molding. Dry at 120°C and bake at 550°C for 4 hours. The above catalyst was cut into 1-3 mm to prepare columnar catalyst matrix B0. 20 grams of matrix catalyst B0 was added to 50 ml of nitric acid solution with a weight content of 10%, and soaked at room temperature for 12 hours. B1 was prepared by drying at 120°C and calcining at 500°C for 2 hours. Molecular sieve catalyst B was obtained by steaming 20 grams of B1 in a 100% steam atmosphere for 4 hours at a temperature of 400° C. and roasting at 550° C. for 3 hours. The weight content of molecular sieve in the prepared catalyst is 85%, and the w...

Embodiment 3

[0041] The preparation process of the molecular sieve catalyst is as follows: 170 grams of ammonia-type ZSM-5 molecular sieve with a molar silicon-aluminum ratio of 80 is mixed with 100 grams of silicon dioxide weight 30% silica sol, a certain amount of lanthanum nitrate is added to mix evenly, and an appropriate amount of 10% Dilute nitric acid is used as extrusion aid to extrude into strips. Dry at 120°C and bake at 550°C for 4 hours. The above catalyst was cut into 1-3 mm to prepare columnar catalyst matrix C0. 20 grams of matrix catalyst C0 was added to 50 ml of nitric acid solution with a weight content of 10%, and soaked at room temperature for 12 hours. Dry at 120°C and bake at 500°C for 2 hours to obtain C1. Molecular sieve catalyst C was obtained by steaming 20 grams of C1 in a 100% steam atmosphere for 2 hours at a treatment temperature of 500° C. and roasting at 550° C. for 3 hours. The weight content of molecular sieve in the prepared catalyst is 85%, and the wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com