Lubricating oil composition used in rotary screw rod air compressor and preparation method thereof

A lubricating oil composition and air compressor technology, applied in the field of lubricating oil, can solve the problems of restricting the normal operation of screw air compressors, insufficient extreme pressure and anti-wear performance, high carbon deposition tendency, etc., to achieve enhanced anti-oxidation and anti-corrosion capabilities, Effect of improving anti-oxidation performance and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] Correspondingly, the present invention also provides a kind of preparation method for the lubricating oil composition of rotary screw air compressor, comprises the following steps:

[0062] Weigh the following components:

[0063] 0.1wt% ~ 3.0wt% antioxidant;

[0064] 0.01wt% ~ 1.5wt% metal rust inhibitor;

[0065] 0.01wt% ~ 1.5wt% metal deactivator;

[0066] 0.5wt%~3.0wt% extreme pressure antiwear agent;

[0067] 0.1wt% ~ 2.0wt% pour point depressant;

[0068] 10ppm~500ppm defoamer;

[0069] and the balance of hydrorefined mineral oil;

[0070] Blending the above components to obtain a lubricating oil composition for a rotary screw air compressor;

[0071] The antioxidant is selected from 2,6-di-tert-butyl-p-cresol, phenyl-α-naphthylamine, dialkyldiphenylamine, butyloctyldiphenylamine and 3,5-di-tert-butyl-4 - one or more of hydroxyphenyl acetates;

[0072] The metal deactivator is selected from one or more of benzotriazole, benzotriazole derivatives, thiadiazo...

Embodiment 1

[0082] Weigh the following components:

[0083] 0.5 wt% butyl octyl diphenylamine;

[0084] 0.5 wt% of 3,5-di-tert-butyl-4-hydroxyphenyl acetate;

[0085] 0.05 wt% oleoyl amino acid;

[0086] 0.05wt% T551 metal deactivator;

[0087] 0.5wt% tricresyl phosphate;

[0088] 0.1wt% T803B pour point depressant;

[0089] 30ppm T901 defoamer;

[0090] And the balance of hydrorefined mineral oil GS600N;

[0091] First, add hydrogenated refined mineral oil into a blending kettle with stirring and heating functions, stir and blend at 50°C, then add the above-mentioned various additive components, and after blending for 3 hours, the obtained

[0092] Lubricating oil composition for rotary screw air compressors.

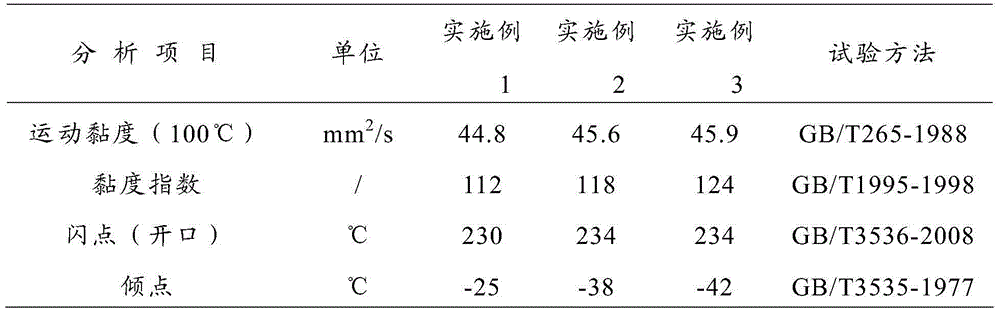

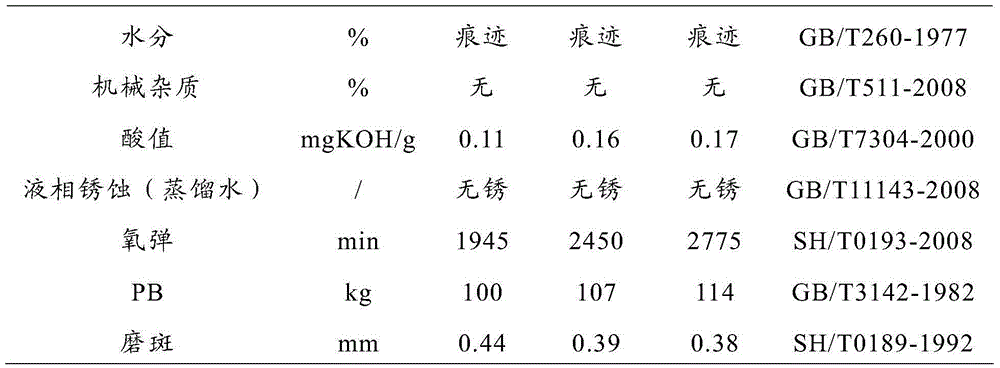

[0093] According to the method described above, the performance evaluation of the obtained rotary screw air compressor oil was carried out. See Table 1 for the results. Table 1 shows the main performance evaluation results of the oil products provided by Examples 1-3 of th...

Embodiment 2

[0099] Weigh the following components:

[0100]1.0wt% butyl octyl diphenylamine;

[0101] 0.6 wt% of 3,5-di-tert-butyl-4-hydroxyphenyl acetate;

[0102] 0.05 wt% oleoyl amino acid;

[0103] 0.07wt% T551 metal deactivator;

[0104] 1.0wt% tricresyl phosphate;

[0105] 0.3wt% T803B pour point depressant;

[0106] 40ppm T902 defoamer;

[0107] And the balance of hydrogenated refined mineral oil Ssangyong 250N;

[0108] First, add hydrogenated refined mineral oil into a blending kettle with stirring and heating functions, stir and blend at 70°C, then add the above-mentioned various additive components, and after blending for 1 hour, obtain a lubricant for rotary screw air compressors oil composition.

[0109] According to the method described above, the performance evaluation of the obtained rotary screw air compressor oil was carried out, and the results are shown in Table 1.

[0110] It can be seen from Table 1 that the lubricating oil product provided by Example 2 of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wear scar diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com