Antiwear hydraulic oil specially used for injection molding machine and preparation method thereof

An anti-wear hydraulic oil, injection molding machine technology, applied in the field of hydraulic system, can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0027] hydraulic oil 1

[0028] Raw material composition (mass percentage): (A) high viscosity index base oil 46#99.4%;

[0029] (B) High base value synthetic calcium sulfonate 0.2%; (E) Antioxidant and anticorrosion agent (ZDDP) 0.3%; (F) Neutral calcium dinonyl naphthalene sulfonate 0.2%; (G) Anti-foaming methyl silicone oil Agent 200ppm.

[0030] Preparation of hydraulic oil 1: take high viscosity index base oil 46#, heat it to 50-60°C, add other ingredients, stir at 50-60°C for 1.0-1.5 hours to obtain the desired hydraulic oil product.

[0031] hydraulic oil 2

[0032] Composition of raw materials (mass percentage): (A) high viscosity index base oil 46#99.2%; (B) 0.2% of high alkali value synthetic calcium sulfonate; (C) antioxidant 2,6 di-tert-butyl p-cresol and Alkylated diphenylamine 1:1 mixture 0.1%; (E) antioxidant and anticorrosion agent (ZDDP) 0.3%; (F) neutral calcium dinonyl naphthalene sulfonate 0.2%; (G) methyl silicone oil antifoaming agent 200ppm.

[0033...

experiment example 2

[0041] Hydraulic oil 3

[0042] Raw material composition (mass percentage): (A) high viscosity index base oil 46#98.8%;

[0043] (B) High base value synthetic calcium sulfonate 0.3%; (C) 0.3% mixture of antioxidant 2,6-di-tert-butyl-p-cresol and alkylated diphenylamine 1:1; (E) antioxidant and anti-corrosion agent (ZDDP) 0.4%; (F) neutral calcium dinonyl naphthalene sulfonate 0.2%; (G) methyl silicone oil antifoaming agent 200ppm.

[0044] The preparation method of hydraulic oil 3 is the same as that of hydraulic oil 1.

[0045] Hydraulic oil 4

[0046] Raw material composition (mass percentage): (A) high viscosity index base oil 46#99.1%; (C) antioxidant 2,6 di-tert-butyl p-cresol and alkylated diphenylamine 1: 1 mixture 0.3%; ( E) 0.4% of antioxidant and anticorrosion agent (ZDDP); (F) 0.2% of neutral calcium dinonyl naphthalene sulfonate; (G) 200ppm of methyl silicone oil antifoaming agent.

[0047] The preparation method of hydraulic oil 4 is the same as that of hydrau...

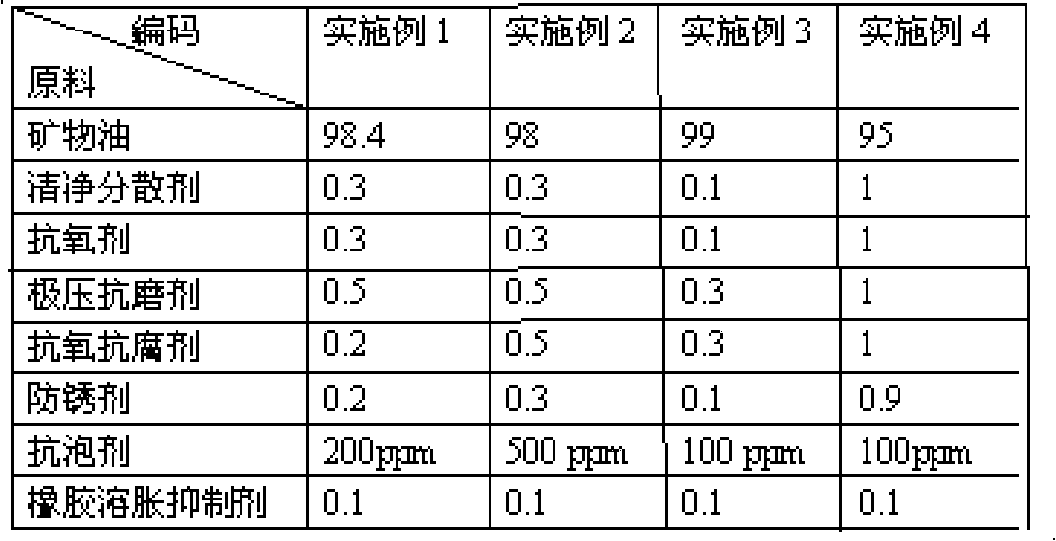

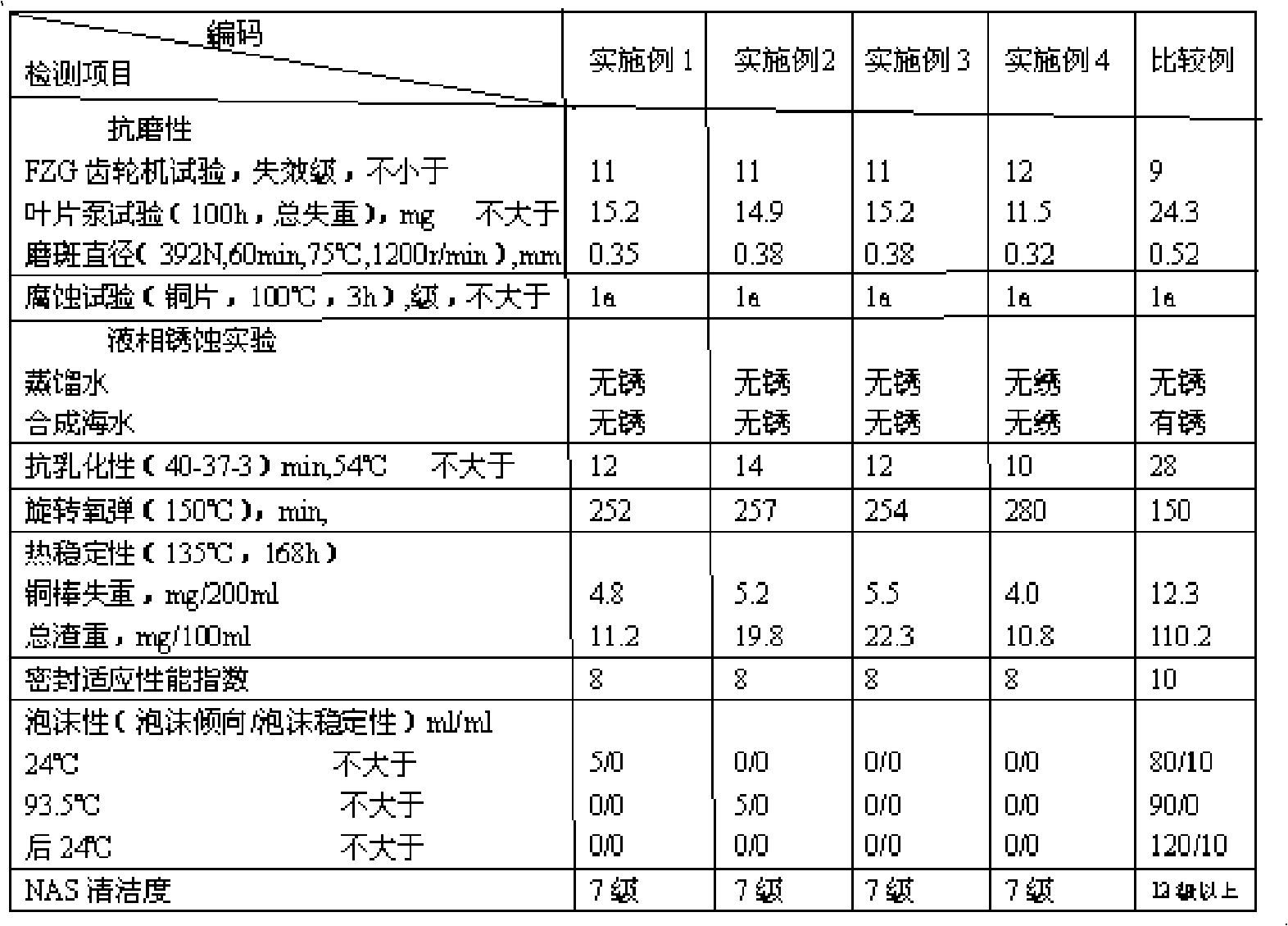

specific Embodiment approach

[0059] Below in conjunction with embodiment, the content of the present invention is described more specifically. It should be understood that the implementation of the present invention is not limited to the following examples, and any modifications and / or changes made to the present invention will fall within the protection scope of the present invention.

[0060] In the present invention, unless otherwise specified, all parts and percentages are weight units, and all equipment and raw materials can be purchased from the market or commonly used in this industry.

[0061] Description of test method

[0062] According to the national standard GB11118.1-94, the anti-wear hydraulic oil of the following examples is tested, and the items include: GB / T5096 test method for copper sheet corrosion of petroleum products; GB / T7305 test method for anti-emulsification performance of petroleum and synthetic fluids; adding inhibitor minerals GB / T11143 test method for antirust performance o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com